Description

. Many products are not yet available. Please contact us to learn more about them

. In case of any inconsistency between the product model and the displayed picture, the model shall prevail. For specific product pictures, please contact us and we will take photos of the goods for confirmation

. We share multiple warehouses around the world, so please understand that it may take several hours to accurately return it to you. Of course, we will respond to your concerns as soon as possible

Product Overview

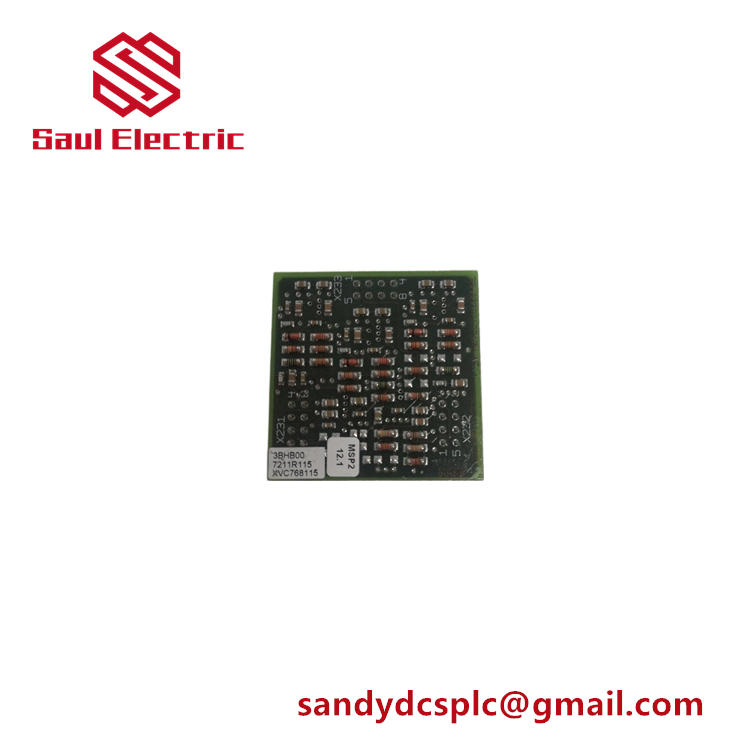

The ABB XVC768116 3BHB007211R116 is a high-performance control module specifically engineered for ABB’s industrial AC drive systems—most notably the ACS880 and ACS600 series, which are widely used in heavy-duty power conversion and motion control applications. As a core logic and interface component, ABB XVC768116 3BHB007211R116 acts as the “control brain” for drive systems, managing power semiconductor switching, real-time torque/speed regulation, and communication with external controllers (e.g., PLCs, DCS). It translates operator or system commands into precise drive outputs, ensuring smooth, efficient operation of high-power industrial equipment.

Designed to withstand the rigors of heavy industry, ABB XVC768116 3BHB007211R116 integrates robust electronic components with advanced thermal management, enabling reliable performance in harsh environments with temperature fluctuations, vibration, and electromagnetic interference. Its seamless compatibility with ABB’s drive ecosystems—including drive software (e.g., Drive composer Pro) and peripheral modules—makes ABB XVC768116 3BHB007211R116 an indispensable solution for applications where precision, durability, and system uptime are critical, such as steel manufacturing, mining, and large-scale HVAC systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | ABB XVC768116 3BHB007211R116 |

| Manufacturer | ABB |

| Product Type | Control Module for ABB Industrial AC Drives (ACS880/ACS600 Series) |

| Compatible Drive Series | ABB ACS880 (medium-voltage), ABB ACS600 (low-voltage) |

| Input Voltage (Logic) | 5 V DC (from drive internal power supply) |

| Operating Temperature | -10°C to 60°C (14°F to 140°F) |

| Communication Interfaces | RS485 (Modbus RTU), Ethernet (optional via adapter), Drive-internal bus |

| Power Consumption | ≤5 W (typical, at 5 V DC input) |

| Isolation Rating | 2.5 kV AC (control circuit to power circuit) |

| Dimensions (W x H x D) | 120 mm x 80 mm x 30 mm (4.72 in x 3.15 in x 1.18 in) |

| Weight | Approximately 0.15 kg (0.33 lbs) |

| Certifications | CE, UL 508, CSA C22.2 No. 14, IEC 61800-5-1 |

| Mounting Type | Drive-internal PCB Slot (compatible with ACS880/ACS600 chassis) |

| Protection Features | Overcurrent protection (logic circuit), overtemperature monitoring |

| Firmware Compatibility | ABB Drive Software v7.0+ (Drive composer Pro compatible) |

Main Features and Advantages

Precision Drive Control: ABB XVC768116 3BHB007211R116 delivers real-time control of drive parameters—including torque, speed, and current—with microsecond-level response times. This precision ensures that connected industrial equipment (e.g., mining conveyors, steel rolling mills) operates at optimal efficiency, reducing energy waste and minimizing mechanical wear. Unlike generic control modules, it is calibrated specifically for ABB’s ACS880/ACS600 drives, eliminating compatibility gaps and ensuring seamless integration with drive hardware.

Robust Industrial Design: Engineered for heavy-industry environments, ABB XVC768116 3BHB007211R116 features a rugged PCB design with conformal coating to resist dust, moisture, and chemical exposure. Its wide operating temperature range (-10°C to 60°C) and vibration resistance (up to 5 g per IEC 60068-2-6) ensure reliability in harsh settings like foundries or offshore platforms, where standard electronic modules would fail. The module’s isolation rating (2.5 kV AC) also protects logic circuits from voltage spikes in high-power drive systems.

Seamless Communication & Integration: ABB XVC768116 3BHB007211R116 supports multiple communication protocols, including Modbus RTU for direct PLC/DCS integration and ABB’s proprietary drive-internal bus for synchronized control of multi-drive systems. It is fully compatible with ABB’s Drive composer Pro software, enabling easy configuration, firmware updates, and diagnostic monitoring—reducing setup time and simplifying maintenance. For advanced network needs, it can connect to Ethernet via optional adapters, supporting Industry 4.0 integration.

Built-In Protective Mechanisms: To safeguard both the module and connected drive systems, ABB XVC768116 3BHB007211R116 includes overcurrent protection for logic circuits and real-time overtemperature monitoring. If abnormal conditions are detected (e.g., excessive current in the logic loop), the module triggers a drive shutdown or alarm, preventing permanent damage to expensive drive components. This proactive protection reduces unplanned downtime and lowers repair costs.

Application Fields

ABB XVC768116 3BHB007211R116 is a critical component in the mining industry, where it controls ABB ACS880 drives powering large equipment like ore conveyors, crushers, and hoists. In underground mines, its rugged design withstands dust, vibration, and temperature swings, while its precision control ensures conveyors operate at consistent speeds—preventing material jams that could halt production. The module’s communication capabilities also allow remote monitoring of drive performance via mine-wide SCADA systems, enabling predictive maintenance.

In steel manufacturing, ABB XVC768116 3BHB007211R116 is used with ACS600 drives to control rolling mills and extrusion machines. These applications require precise torque control to shape steel without defects; the module’s real-time response ensures that rolling speeds adjust instantly to material thickness changes, improving product quality and reducing scrap. Its overtemperature protection is also critical here, as steel mills generate extreme heat that could damage less robust control modules.

The renewable energy sector relies on ABB XVC768116 3BHB007211R116 in wind turbine converters (powered by ACS880 drives). The module manages the conversion of variable-speed wind energy into grid-compatible AC power, adjusting to wind speed fluctuations to maximize energy output. Its compatibility with Ethernet (via adapters) allows integration with wind farm management systems, enabling centralized monitoring of multiple turbines.

Additionally, ABB XVC768116 3BHB007211R116 finds applications in marine propulsion systems, where it controls ACS880 drives powering ship thrusters. Its moisture-resistant conformal coating and vibration resistance make it suitable for marine environments, while its precise speed control ensures smooth maneuvering of vessels—critical for safety in ports or rough seas. It also supports communication with shipboard control systems, enabling integrated navigation and propulsion management.

Related Products

ABB PCS6000

ABB IGCT 5SHY4045L0006 3BHB030310R0001 Module

ABB PPD539A102 3BHE039770R0102

ABB PPD513 | AC800PEC | excitation controller | PP D513

PPD513A25-111615 3BHE039724R2565

HS:8538 9000.00

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com