Description

Many products are not yet available—feel free to contact us for more options.

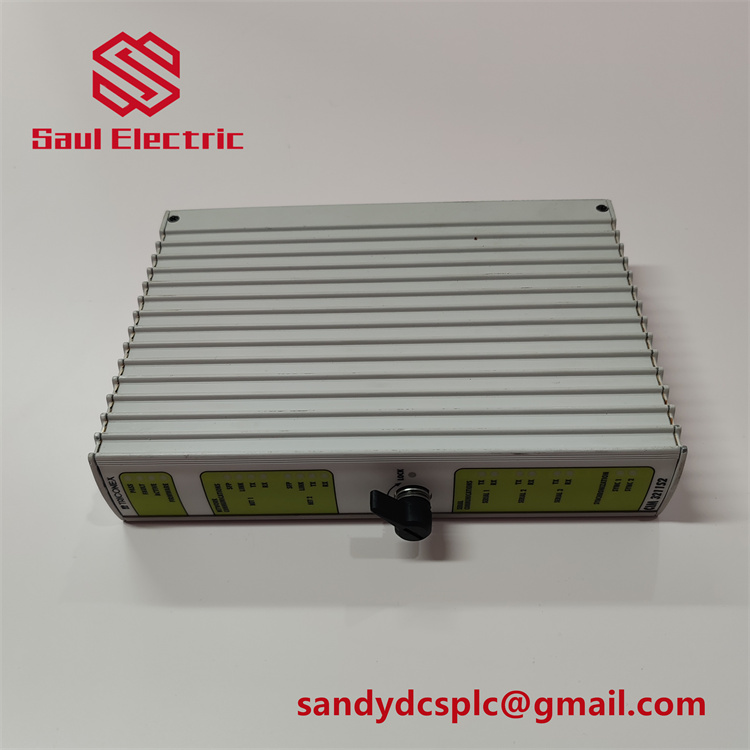

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Triconex 3721 Analog Input Module

Product Overview

The Triconex 3721 is a high-performance analog input module engineered for safety-critical industrial automation systems, delivering precise signal acquisition and robust fault tolerance. As part of the Triconex TMR (Triple Modular Redundancy) platform, this module is designed to meet the rigorous demands of applications requiring SIL 3 certification, such as emergency shutdown systems and process monitoring in oil & gas, petrochemical, and power generation industries.

Featuring 32 differential input channels with DC-coupled design, the Triconex 3721 supports voltage ranges of 0–5 VDC or ±5 VDC, ensuring compatibility with a wide array of field devices. Its programmable resolution (12-bit or 14-bit) and ±0.15% full-scale accuracy enable detailed measurement of process variables like temperature, pressure, and flow. The module’s advanced Total Fault Management (TFM) technology continuously monitors for faults, ensuring seamless operation even in the presence of single-point failures.

Integrated with Triconex’s TMR architecture, the Triconex 3721 employs a 2-out-of-3 voting mechanism to eliminate single points of failure, enhancing system reliability and availability. Its compact form factor and hot-swap capability facilitate easy integration into existing distributed control systems (DCS), reducing downtime during maintenance. Backed by comprehensive diagnostics and industry-standard certifications (CE, UL, FM, CSA), this module is a cornerstone for ensuring operational safety and compliance in mission-critical environments.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | Triconex 3721 |

| Manufacturer | Triconex |

| Product Type | Analog Input Module |

| Input Type | Differential, DC-coupled |

| Voltage Range | 0–5 VDC or ±5 VDC (±6% tolerance) |

| Number of Channels | 32 |

| Resolution | 12-bit or 14-bit programmable |

| Accuracy | ±0.15% of full scale (0–60°C) |

| Input Update Rate | 10 ms |

| Common Mode Rejection | -85 dB (DC–100 Hz) |

| Overvoltage Protection | 150 VDC/115 VAC continuous |

| Operating Temperature | -40°C to +70°C |

| Dimensions | 2.2 cm (height) × 40.8 cm (width) × 40 cm (depth) |

| Weight | 2.06 kg |

| Certification | CE, UL, FM, CSA |

Main Features and Advantages

Triple Modular Redundancy (TMR) Architecture: The Triconex 3721 leverages TMR technology to maintain operation even with two faulty channels, ensuring 24/7 system availability. Each channel independently processes signals, with a mid-value selection algorithm ensuring data integrity.

High-Precision Signal Conditioning: With 14-bit resolution and ±0.15% accuracy, the module captures 细微 process variations, enabling proactive decision-making in critical processes. Its DC-coupled design minimizes noise interference, ideal for noisy industrial environments.

Comprehensive Diagnostics: Built-in self-testing and fault detection mechanisms continuously monitor channel health, providing real-time status updates to facilitate predictive maintenance. Fault indicators and chassis alarms promptly alert operators to issues.

Hot-Swap Capability: The module supports online replacement without disrupting system operation, reducing downtime and enhancing maintenance efficiency. This feature is critical for industries where even brief interruptions can lead to significant losses.

Wide Compatibility: Designed for seamless integration with Triconex’s Tricon system, the Triconex 3721 works with external termination panels (ETPs) and supports industry-standard communication protocols like Modbus RTU, simplifying integration into complex control networks.

Application Areas

The Triconex 3721 excels in safety-critical applications across industries requiring high-integrity control systems:

- Oil & Gas: Used in offshore platforms and refineries for monitoring pressure, temperature, and flow in pipelines, ensuring safe operation of wellheads and separation units.

- Chemical Processing: Deployed in reactor monitoring and distillation columns to maintain precise control over chemical reactions, preventing hazardous conditions.

- Power Generation: Monitors turbine performance and boiler parameters in thermal power plants, enabling early detection of anomalies to avoid catastrophic failures.

- Pharmaceuticals: Ensures compliance with strict quality standards by accurately measuring environmental conditions in cleanrooms and sterile manufacturing environments.

In each scenario, the Triconex 3721’s combination of high accuracy, fault tolerance, and SIL 3 certification makes it a preferred choice for applications where human safety and asset protection are paramount.

Related Products

- Triconex 3703E: A 16-channel analog input module with isolated inputs, ideal for applications requiring enhanced noise immunity.

- Triconex 3704E: High-density analog input module supporting 64 channels, suitable for large-scale process monitoring.

- Triconex 3706A: Specialized for thermocouple inputs, providing direct temperature measurement in extreme environments.

- Triconex 3625: Digital output module designed for fail-safe actuation of valves and motors in safety systems.

- Triconex 3008: TMR controller module for executing control logic and coordinating I/O modules in complex systems.

- Triconex 8310: Power supply module ensuring reliable energy distribution to Tricon chassis components.

These products complement the Triconex 3721 in building comprehensive, scalable safety systems.

Installation and Maintenance

Installation Preparation:

Ensure the control system chassis is powered off and properly grounded before installation. Verify compatibility with the Tricon backplane and external termination panel (ETP). Use Triconex’s TriStation 1131 software to configure input ranges, resolution, and diagnostic settings. The module is keyed for correct alignment in the chassis, preventing misinstallation.

Ensure the control system chassis is powered off and properly grounded before installation. Verify compatibility with the Tricon backplane and external termination panel (ETP). Use Triconex’s TriStation 1131 software to configure input ranges, resolution, and diagnostic settings. The module is keyed for correct alignment in the chassis, preventing misinstallation.

Maintenance Recommendations:

Regularly inspect the Triconex 3721 for physical damage or loose connections. Utilize the module’s built-in diagnostics to monitor channel health and update firmware as recommended by the manufacturer. For faulted channels, perform hot-swap replacement using a certified spare module to maintain system continuity. Schedule annual calibration checks to ensure accuracy remains within specified limits.

Regularly inspect the Triconex 3721 for physical damage or loose connections. Utilize the module’s built-in diagnostics to monitor channel health and update firmware as recommended by the manufacturer. For faulted channels, perform hot-swap replacement using a certified spare module to maintain system continuity. Schedule annual calibration checks to ensure accuracy remains within specified limits.

Product Warranty

The Triconex 3721 comes with a 1-year warranty covering defects in materials and workmanship. This includes free repair or replacement of faulty components, backed by a global network of technical support. Customers receive access to detailed documentation, software updates, and 24/7 assistance from Triconex-certified engineers to address operational challenges. The warranty underscores the module’s reliability and the manufacturer’s commitment to delivering long-term value in safety-critical applications.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com