Description

Many products are not yet available—feel free to contact us for more options.

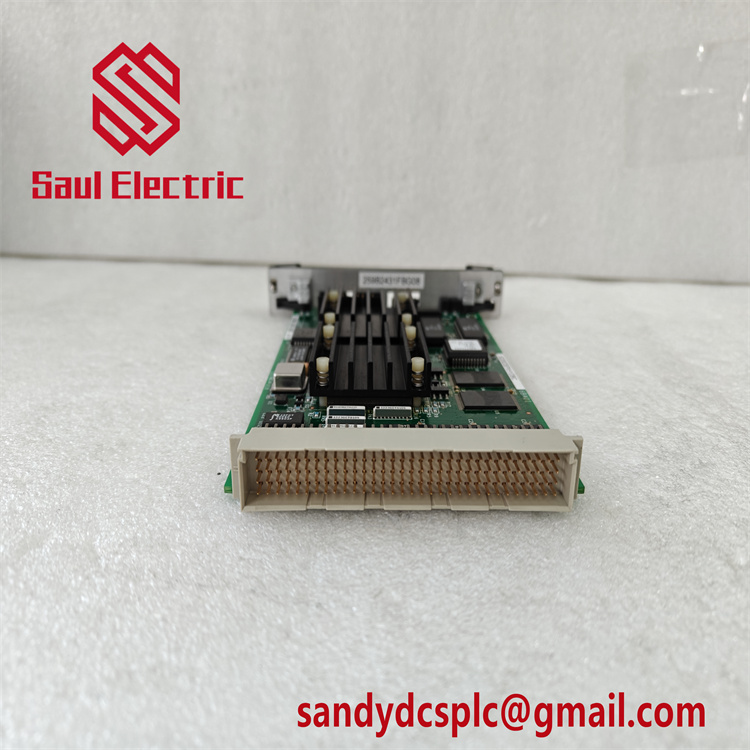

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Product Overview

The GE IS200SRTDH1A is a precision terminal board designed for industrial temperature monitoring systems, specifically engineered to interface with resistance temperature detectors (RTDs) in GE’s Mark VI/Mark VIe Speedtronic turbine control platforms. As a critical component in hazardous environments, it ensures stable signal transmission between RTD sensors and upstream modules like IS220PRTDH1A, enabling accurate temperature measurements for steam/gas turbines and industrial processes. The GE IS200SRTDH1A features robust electrical isolation and compact DIN-rail compatibility, making it ideal for power generation, oil refineries, and chemical plants where reliability under extreme conditions is paramount.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200SRTDH1A |

| Manufacturer | GE (General Electric) |

| Product Type | RTD Terminal Board |

| Compatible Modules | IS220PRTDH1A (primary interface) |

| Hazardous Area Certification | Approved for Class I/Div 2 with IS220PRTDH1A |

| Input Type | 2/3/4-wire RTD connections (Pt100, Pt1000) |

| Isolation Voltage | 1500V AC (channel-to-ground) |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 340mm × 180mm × 100mm (13.4″ × 7.1″ × 3.9″) |

| Weight | 2.0kg (4.4 lbs) |

| Certifications | UL, CE Marked |

| Installation | DIN rail (EN 60715 compliant) |

| Cable Requirements | Shielded twisted pair, local electrical code compliance |

Key Features and Advantages

High-Precision Signal Integrity: The GE IS200SRTDH1A eliminates ground loops and electromagnetic interference (EMI) via 1500V optical isolation, critical for maintaining ±0.1°C accuracy in turbine temperature monitoring. Its gold-plated terminals ensure minimal contact resistance for stable RTD signal transmission.

Hazardous Environment Resilience: Certified for Class I/Div 2 hazardous locations when paired with IS220PRTDH1A, the terminal board withstands corrosive gases, dust, and humidity levels up to 95% non-condensing. Conformal coating on PCBs extends service life in offshore platforms or steel mills.

Simplified Integration: Plug-and-play compatibility with GE Mark VIe systems reduces configuration time. Modular design supports hot-swapping during maintenance, minimizing turbine downtime. Front-panel LEDs provide real-time status for power, communication, and fault alerts.

Application Areas

Power Generation: In gas/steam turbines, the GE IS200SRTDH1A interfaces with RTDs monitoring bearing temperatures and exhaust gases, enabling predictive maintenance to prevent overheating failures.

Oil & Gas Refineries: Deployed in compressor stations for pipeline temperature monitoring, ensuring SIL-2 compliance in safety-critical shutdown systems.

Chemical Processing: Supports batch reactors and distillation columns where precise temperature control (±1°C) is vital for reaction efficiency and safety.

Related Products

IS200TBAIH1CDD – Analog Input Terminal Board

GE IS200JPDFGIADD Processing Module(XIONGBA) | XIONGBA

IS200TRPGH2BDD – Primary Gas Turbine Trip Output Board

Installation and Maintenance

Installation Preparation: Mount vertically on DIN rails with ≥50mm clearance from heat sources. Use shielded cables (e.g., Belden 8761) for RTD connections, ensuring insulation meets NEC/CEC standards. Verify grounding resistance <1Ω before power-up.

Maintenance Recommendations: Clean terminals annually with isopropyl alcohol to prevent oxidation. Inspect cable integrity quarterly; replace if shield damage exceeds 30%. Calibration drift checks recommended every 6 months using a precision RTD simulator.

Product Assurance

The GE IS200SRTDH1A includes a 1-year global warranty covering material defects. GE provides 24/7 technical support and on-site service within 48 hours for critical failures. All boards undergo MIL-STD-810G vibration testing and ISO 9001-certified production, with field failure rates <0.2%.

HS:7326909000- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com