Description

Product Overview

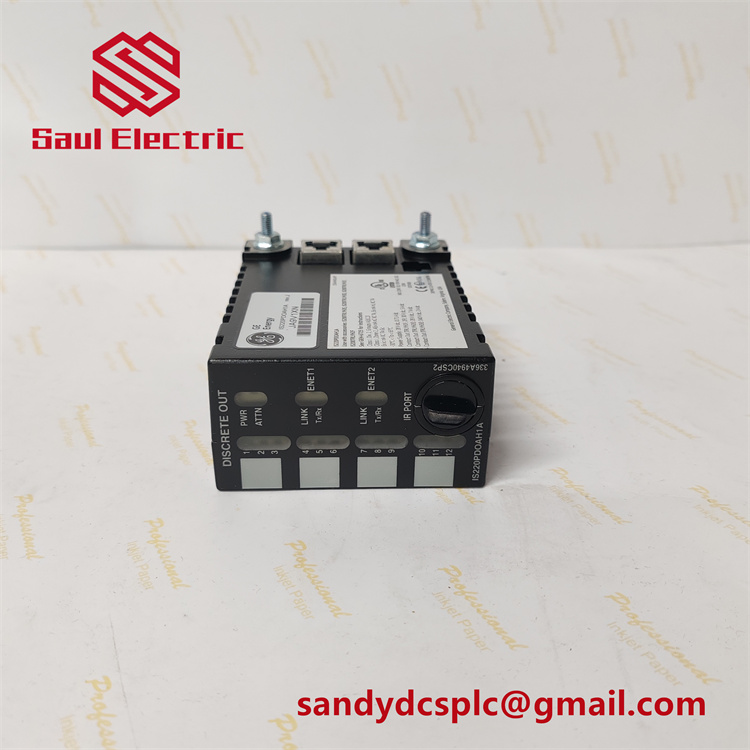

The GE IS220PSCAH1B is a high-performance serial communication I/O module belonging to GE’s Mark VIe control system series, specifically engineered to facilitate reliable data transmission between industrial control systems and field devices. As a critical communication interface in GE’s Speedtronic turbine control architecture, GE IS220PSCAH1B integrates six individually configurable serial transceiver channels with dual Ethernet connectivity, enabling seamless integration of diverse industrial protocols within complex automation ecosystems.

Designed for mission-critical applications, GE IS220PSCAH1B supports RS485 half-duplex, RS232, and RS422 communication standards, making it a versatile solution for connecting legacy and modern devices in power generation and heavy industrial environments. Its multi-layer PCB design with surface-mount components ensures robust performance in harsh conditions, while its compatibility with hazardous location terminal boards extends its usability to explosive environments. The GE IS220PSCAH1B plays a pivotal role in Mark VIe systems by consolidating serial communication functions, reducing system complexity, and enhancing data integrity across industrial networks.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS220PSCAH1B |

| Manufacturer | GE |

| Product Type | Serial Communication I/O Module (Mark VIe Series) |

| Serial Channels | 6 configurable channels |

| Supported Protocols | RS485 half-duplex, RS232, RS422 |

| Ethernet Ports | Dual 100Mb full-duplex RJ45 |

| Power Supply | 22.5-28.6 VDC (max current 0.36 A) |

| Operating Temperature Range | -40 to 70°C (-40 to 158°F) |

| Storage Temperature Range | -40 to 85°C (-40 to 185°F) |

| Physical Dimensions | 8.2 cm (H) × 12.2 cm (W) × 6 cm (D) |

| Weight | 0.36 kg |

| Terminal Connection | DC-62 pin connector |

| Certifications | Compatible with ATEX Zone 2, UL 508 compliant |

| Redundancy Support | Simplex, dual, and triple-redundant configurations |

| Sensitivity | ESD-sensitive device |

Main Features and Advantages

Multi-protocol flexibility: GE IS220PSCAH1B offers six independently configurable serial channels that support RS485, RS232, and RS422 standards, enabling seamless communication with diverse field devices such as sensors, actuators, and meters. This versatility eliminates the need for multiple protocol-specific modules, reducing system complexity and installation costs in mixed-technology environments.

Dual Ethernet redundancy: Equipped with dual 100Mb full-duplex Ethernet ports, GE IS220PSCAH1B ensures high-speed, reliable data transmission to Mark VIe controllers. The redundant network design minimizes communication downtime by automatically switching to alternate paths during network disruptions—a critical feature for maintaining operational continuity in turbine control and other mission-critical applications.

Hazardous environment compatibility: When paired with approved terminal boards (IS200SSCAH1A/2A), GE IS220PSCAH1B operates safely in potentially explosive environments, meeting stringent ATEX Zone 2 requirements. This certification expands its application range to oil and gas facilities, chemical plants, and other hazardous industrial settings.

Robust industrial design: Constructed with multi-layer PCBs and surface-mount components, GE IS220PSCAH1B delivers exceptional durability in harsh conditions, including extreme temperature fluctuations (-40 to 70°C) and high vibration environments. Its self-diagnostic capabilities continuously monitor communication integrity, generating alarms for configurable thresholds to enable proactive maintenance.

Application Fields

GE IS220PSCAH1B is primarily deployed in gas and steam turbine control systems within power generation facilities, where it serves as the critical communication link between Mark VIe controllers and field devices such as vibration monitors, temperature transmitters, and valve positioners. Its multi-protocol support allows seamless integration with both legacy and modern instruments, ensuring comprehensive data acquisition for turbine performance optimization and condition monitoring.

In oil and gas processing plants, GE IS220PSCAH1B enables reliable communication in hazardous areas, connecting Mark VIe systems to pipeline flow meters, pressure sensors, and safety interlocks. Its ATEX Zone 2 compatibility ensures safe operation in potentially explosive atmospheres, while its redundant Ethernet design maintains data flow during network disturbances common in remote pipeline operations.

The module also finds application in chemical processing and heavy manufacturing, where it consolidates serial communication from diverse process instruments into the Mark VIe control architecture. GE IS220PSCAH1B facilitates centralized monitoring and control of batch processes, material handling systems, and environmental monitoring equipment, enhancing operational visibility and control precision across complex industrial ecosystems.

Related Products

- GE IS220PSCAH1A: Predecessor serial communication module with similar functionality but different voltage requirements (27.4-28.6 VDC), compatible with GE IS220PSCAH1B in mixed system upgrades.

- GE IS200SSCAH1A: Terminal board specifically designed for GE IS220PSCAH1B in hazardous location installations, providing secure connections and environmental protection.

- GE IS220PPRFH1B: Profibus gateway module that complements GE IS220PSCAH1B by extending communication capabilities to Profibus-based devices in Mark VIe systems.

- GE IS220PAICH1B: Analog I/O module that works with GE IS220PSCAH1B to provide comprehensive signal acquisition and control in industrial processes.

- GE IS220PDIAH1B: Discrete input module whose status data can be transmitted through GE IS220PSCAH1B to Mark VIe controllers for system-wide monitoring.

- GE IS221PSCAH1B: Coated version of GE IS220PSCAH1B with enhanced environmental protection for extreme dust or moisture conditions.

- GE IS220UCSAH1A: Universal control module that receives data from GE IS220PSCAH1B to execute control logic in Mark VIe systems.

Installation and Maintenance

Installation preparation: Before installing GE IS220PSCAH1B, verify compatibility with the target Mark VIe rack and ensure the power supply meets the 22.5-28.6 VDC requirement. Use ESD protection equipment (wristbands, grounded workstations) when handling the module as it is static-sensitive. Select appropriate terminal boards (IS200SSCAH series for hazardous locations) and confirm all communication cables meet protocol-specific requirements (e.g., shielded twisted-pair for RS485). Power off the system during installation to prevent electrical damage.

Maintenance recommendations: Conduct quarterly visual inspections of GE IS220PSCAH1B to check for loose connections, dust accumulation, or corrosion on terminals. Verify Ethernet link status indicators during routine system checks to ensure redundant communication paths are active. When reconfiguring serial channels, use Control ST software v04.07.08c or higher to maintain compatibility. If communication faults occur, check for proper grounding, cable integrity, and protocol mismatches before replacing GE IS220PSCAH1B. Store spare modules in ESD-protective containers in dry environments (-40 to 85°C storage range).

Product Guarantee

GE IS220PSCAH1B is backed by GE’s rigorous quality assurance program, ensuring reliable performance in critical industrial applications. The module undergoes comprehensive testing, including environmental stress screening, protocol compatibility verification, and hazardous location certification validation. GE IS220PSCAH1B comes with a 1-year warranty covering defects in materials and workmanship, with optional extended coverage available through GE service contracts.

Customers benefit from GE’s global technical support network, providing expert assistance for installation, configuration, and troubleshooting of GE IS220PSCAH1B. GE’s commitment to quality ensures that each module meets strict industrial standards, delivering consistent communication performance to support safe and efficient operation of Mark VIe control systems in diverse industrial environments.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com