Description

Many products are not yet available—feel free to contact us for more options.

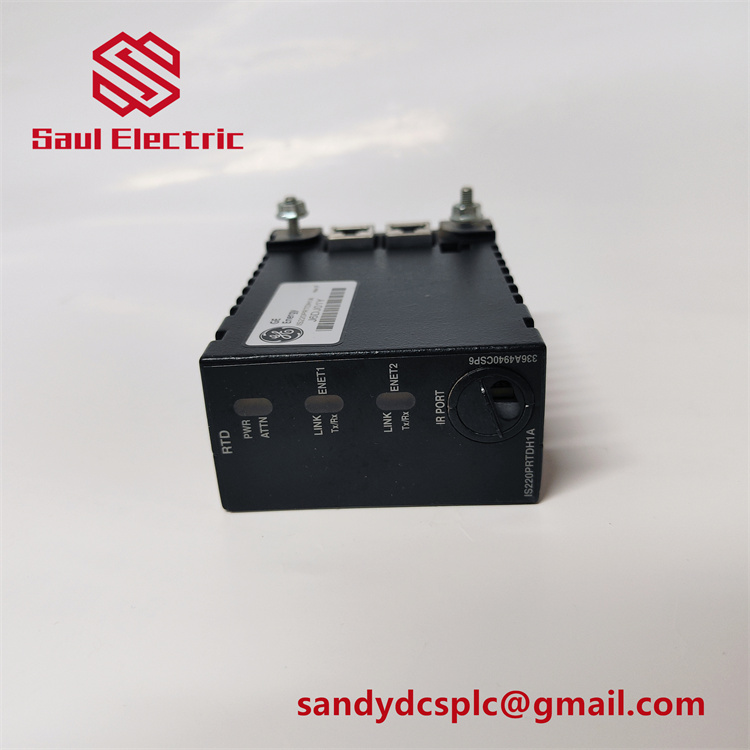

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Product Overview

The GE IS220PPRAH1A is a high-performance power regulation module specifically designed for the GE Mark VIe control system, a leading platform in industrial automation for critical power and process applications. As a core component of the Mark VIe family, GE IS220PPRAH1A delivers precise voltage and current regulation to ensure stable power distribution to key control system components, such as I/O modules, processors, and communication interfaces. Its integration with the Mark VIe architecture enables seamless data exchange and system-wide monitoring, making it an essential element for maintaining operational reliability in demanding industrial environments.

By providing consistent power output even under fluctuating input conditions, GE IS220PPRAH1A minimizes the risk of system downtime caused by power irregularities—a critical advantage for industries where unplanned outages result in significant productivity losses. Additionally, GE IS220PPRAH1A is engineered to meet strict industrial standards for durability and performance, ensuring compatibility with existing Mark VIe installations while supporting future system expansions.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS220PPRAH1A |

| Manufacturer | GE |

| Product Type | Power Regulation Module (Mark VIe Series) |

| Input Voltage Range | 100-240 VAC (50/60 Hz) |

| Output Voltage | 24 VDC (regulated, ±0.5% accuracy) |

| Maximum Output Current | 5 A |

| Physical Dimensions | 140 mm (W) × 220 mm (H) × 80 mm (D) |

| Operating Temperature | -10°C to 60°C (14°F to 140°F) |

| Storage Temperature | -40°C to 85°C (-40°F to 185°F) |

| Communication Interface | Modbus RTU (integrated with Mark VIe backplane) |

| Installation Type | DIN Rail or Panel Mount (compatible with Mark VIe racks) |

| Certifications | UL 508, CE, ATEX (Zone 2) |

| Power Efficiency | ≥90% (at full load) |

| Redundancy Support | Yes (compatible with 1+1 redundant configurations) |

Main Features and Advantages

Precise Power Regulation: GE IS220PPRAH1A offers exceptional output voltage stability (±0.5% accuracy) across varying load conditions, ensuring sensitive Mark VIe control components receive consistent power. This precision prevents voltage spikes or drops that could corrupt data or damage hardware, critical for maintaining system integrity in power generation and process control applications.

Robust Fault Protection: The module integrates comprehensive protection mechanisms, including overvoltage, overcurrent, and overtemperature safeguards. If an abnormal condition is detected, GE IS220PPRAH1A automatically triggers protective actions (such as output shutdown or current limiting) to prevent module failure and protect connected equipment, reducing maintenance costs and downtime.

Seamless Mark VIe Integration: Designed exclusively for the GE Mark VIe platform, GE IS220PPRAH1A leverages the system’s backplane communication to enable real-time status monitoring and remote configuration. Operators can access voltage, current, and temperature data via the Mark VIe HMI, simplifying troubleshooting and reducing the need for on-site intervention.

Industrial-Grade Durability: Constructed with high-quality components and a rugged enclosure, GE IS220PPRAH1A withstands harsh industrial environments, including extreme temperatures, vibration, and electrical noise. This durability ensures long-term reliability, even in applications like gas turbines, steam turbines, and heavy-duty manufacturing lines.

Application field

GE IS220PPRAH1A is primarily deployed in power generation industries, where it serves as a critical power regulation component for GE Mark VIe-controlled gas and steam turbine systems. In these applications, the module ensures consistent power delivery to turbine control units, sensor interfaces, and actuation systems—enabling precise speed, pressure, and load control that is essential for efficient and safe power production. Any power instability in these systems could lead to turbine trips or reduced efficiency, making GE IS220PPRAH1A a vital safeguard against operational disruptions.

Beyond power generation, GE IS220PPRAH1A is also used in heavy industrial sectors, such as oil and gas refining and chemical processing. In these environments, the module powers Mark VIe-based process control systems that manage critical operations like fluid flow, temperature, and pressure regulation. Its ability to operate reliably in harsh conditions (e.g., high temperatures, electrical interference) ensures that process control systems remain operational, minimizing the risk of production delays or safety incidents.

Additionally, GE IS220PPRAH1A finds application in marine propulsion systems and industrial drive controls, where it supports the power needs of Mark VIe-based control architectures. In these mobile or high-vibration environments, the module’s robust design and fault protection features ensure continuous performance, even under dynamic operating conditions.

Related Products

IS200TBAIH1CDD – Analog Input Terminal Board

GE IS200JPDFGIADD Processing Module(XIONGBA) | XIONGBA

IS200TRPGH2BDD – Primary Gas Turbine Trip Output Board

PPD513A25-111615 3BHE039724R2565

Installation and Maintenance

Preparations before Installation: Before installing GE IS220PPRAH1A, verify compatibility with the target GE Mark VIe rack (ensure the rack supports Mark VIe power modules) and check that the input power supply matches the module’s 100-240 VAC range. Inspect the module for physical damage (e.g., bent pins, cracked enclosures) and ensure all mounting hardware (DIN rail clips or panel screws) is compatible with the module’s dimensions. Power off the Mark VIe system and disconnect the main power supply to prevent electrical shock during installation.

Maintenance suggestions: Conduct monthly visual inspections of GE IS220PPRAH1A to check for loose connections, dust accumulation, or signs of overheating (e.g., discolored components). Use a multimeter to verify that the module’s output voltage remains within the 24 VDC ±0.5% range—any deviation may indicate a potential fault. Every 6 months, clean the module’s vents and cooling surfaces to maintain optimal thermal performance, as dust buildup can reduce efficiency and increase the risk of overtemperature shutdowns. If GE IS220PPRAH1A triggers a fault alarm, refer to the Mark VIe system HMI for diagnostic data (e.g., overcurrent, overvoltage) before replacing the module to avoid unnecessary downtime.

Product Guarantee

GE IS220PPRAH1A is backed by a comprehensive quality guarantee, reflecting GE’s commitment to delivering reliable industrial automation components. The module undergoes rigorous testing during manufacturing, including environmental stress testing (temperature, vibration) and electrical performance validation, to ensure compliance with GE’s strict quality standards. In the unlikely event of a defect in materials or workmanship, GE IS220PPRAH1A is covered by a standard warranty (details available upon purchase), which includes repair or replacement of the module at no additional cost to the customer.

GE also provides dedicated technical support for GE IS220PPRAH1A, with a team of industrial automation experts available to assist with installation, troubleshooting, and maintenance queries. Customers can access technical documentation, including user manuals and diagnostic guides, to ensure optimal performance of GE IS220PPRAH1A in their Mark VIe systems. Additionally, GE offers optional extended service contracts for GE IS220PPRAH1A, providing enhanced support (e.g., priority response times, on-site service) to minimize downtime and maximize the module’s operational lifespan.

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com