Description

Many products are not yet available—feel free to contact us for more options.

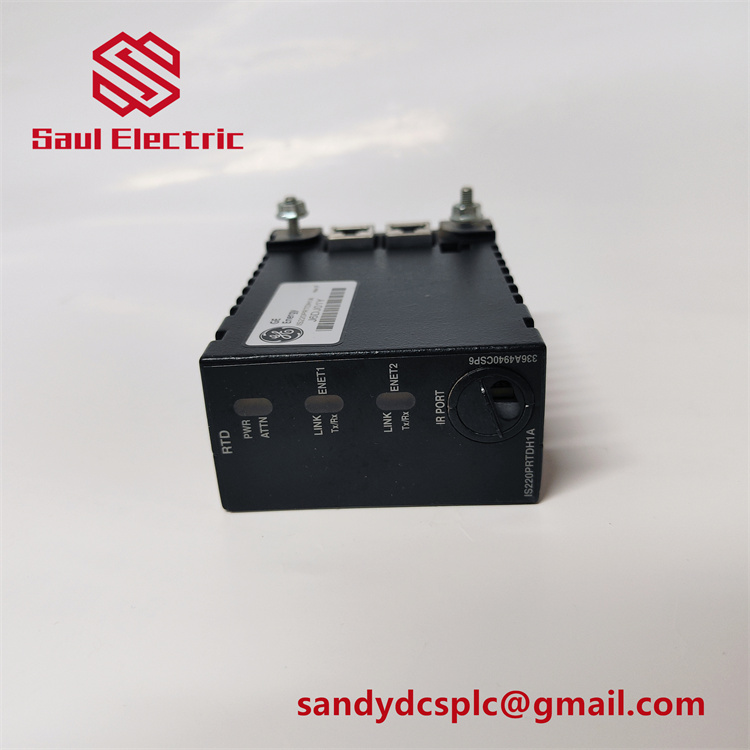

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Product Overview

The GE IS220PAOCH1B is a high-precision analog output module engineered for GE’s Mark VIe distributed control system, a cornerstone platform in industrial automation for critical machinery. As a key component of the Mark VIe family, the IS220PAOCH1B converts digital signals from the controller into analog outputs (0–20 mA) to drive actuators, valves, and other process control devices, ensuring seamless integration in turbine control systems, power generation units, and industrial automation workflows.

Designed for reliability in harsh environments, the GE IS220PAOCH1B features eight isolated output channels with 16-bit resolution, enabling precise control over process variables such as pressure, flow, and temperature. Its dual RJ45 Ethernet ports support high-speed data communication, while built-in diagnostics continuously monitor output integrity and thermal conditions, providing real-time feedback to prevent failures. The module’s compact form factor (132 mm x 94 mm x 35 mm) allows for space-efficient installation in standard Mark VIe racks, making it ideal for retrofitting existing systems or scaling new configurations.

Compliant with international safety standards like ATEX Zone 2 and UL certification for hazardous locations, the IS220PAOCH1B is certified for use in explosive atmospheres, ensuring operational safety in oil refineries, chemical plants, and offshore platforms. Its redundant power input and hot-swap capability minimize downtime during maintenance, while the 24V DC power supply ensures stable operation across a wide temperature range (-40°C to 70°C). By integrating the GE IS220PAOCH1B, users achieve enhanced process control accuracy, reduced maintenance costs, and compliance with rigorous industrial regulations.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS220PAOCH1B |

| Manufacturer | GE |

| Product Type | Analog Output Module |

| Output Channels | 8 (isolated) |

| Output Range | 0–20 mA |

| Resolution | 16-bit |

| Input Voltage | 24V DC ±10% |

| Communication Interfaces | Dual RJ45 Ethernet (10/100 Mbps) |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Isolation | 2.5 kV DC between channels |

| Current Compliance | 18 V DC |

| Weight | 0.2 kg |

| Certifications | ATEX Zone 2, UL (hazardous locations) |

Main Features and Advantages

Precision Control:

The GE IS220PAOCH1B delivers 16-bit resolution for analog outputs, ensuring fine-grained control over critical process variables. Its 0–20 mA output range is compatible with most industrial actuators, enabling seamless integration into existing systems.

The GE IS220PAOCH1B delivers 16-bit resolution for analog outputs, ensuring fine-grained control over critical process variables. Its 0–20 mA output range is compatible with most industrial actuators, enabling seamless integration into existing systems.

Rugged Design:

With a wide temperature operating range (-40°C to +70°C) and compliance with ATEX and UL standards, the module withstands extreme environmental conditions, making it suitable for hazardous industrial settings.

With a wide temperature operating range (-40°C to +70°C) and compliance with ATEX and UL standards, the module withstands extreme environmental conditions, making it suitable for hazardous industrial settings.

Hot-Swap Capability:

The module can be replaced without powering down the system, minimizing downtime during maintenance. This feature is critical for industries where continuous operation is essential.

The module can be replaced without powering down the system, minimizing downtime during maintenance. This feature is critical for industries where continuous operation is essential.

Advanced Diagnostics:

Built-in temperature sensors and output current monitoring provide real-time feedback on module health, allowing proactive maintenance to prevent unplanned shutdowns.

Built-in temperature sensors and output current monitoring provide real-time feedback on module health, allowing proactive maintenance to prevent unplanned shutdowns.

Redundant Communication:

Dual Ethernet ports support redundant network configurations, ensuring reliable data transmission even in the event of a single port failure.

Dual Ethernet ports support redundant network configurations, ensuring reliable data transmission even in the event of a single port failure.

Application Areas

Power Generation:

In thermal and gas turbine power plants, the GE IS220PAOCH1B controls fuel valves, steam turbines, and generator excitation systems, ensuring precise regulation of power output. Its ATEX certification makes it suitable for use in potentially explosive environments.

In thermal and gas turbine power plants, the GE IS220PAOCH1B controls fuel valves, steam turbines, and generator excitation systems, ensuring precise regulation of power output. Its ATEX certification makes it suitable for use in potentially explosive environments.

Oil and Gas:

Deployed in offshore platforms and refineries, the module drives control valves in pipeline systems and compressor stations, maintaining optimal flow rates while adhering to safety protocols in hazardous zones.

Deployed in offshore platforms and refineries, the module drives control valves in pipeline systems and compressor stations, maintaining optimal flow rates while adhering to safety protocols in hazardous zones.

Chemical Processing:

Used in reactor control systems, the IS220PAOCH1B regulates temperature and pressure by controlling cooling systems and agitators, preventing runaway reactions and ensuring product quality.

Used in reactor control systems, the IS220PAOCH1B regulates temperature and pressure by controlling cooling systems and agitators, preventing runaway reactions and ensuring product quality.

Water Treatment:

Integrated into wastewater treatment plants, the module adjusts pump speeds and chemical dosing systems based on real-time sensor data, optimizing treatment efficiency and reducing energy consumption.

Integrated into wastewater treatment plants, the module adjusts pump speeds and chemical dosing systems based on real-time sensor data, optimizing treatment efficiency and reducing energy consumption.

Marine Propulsion:

In shipboard systems, the GE IS220PAOCH1B manages engine fuel injection and propulsion systems, ensuring reliable performance during long voyages in harsh marine environments.

In shipboard systems, the GE IS220PAOCH1B manages engine fuel injection and propulsion systems, ensuring reliable performance during long voyages in harsh marine environments.

Related Products

IS200TBAIH1CDD – Analog Input Terminal Board

GE IS200JPDFGIADD Processing Module(XIONGBA) | XIONGBA

IS200TRPGH2BDD – Primary Gas Turbine Trip Output Board

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com