Description

Many products are not yet available—feel free to contact us for more options.

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Product Overview

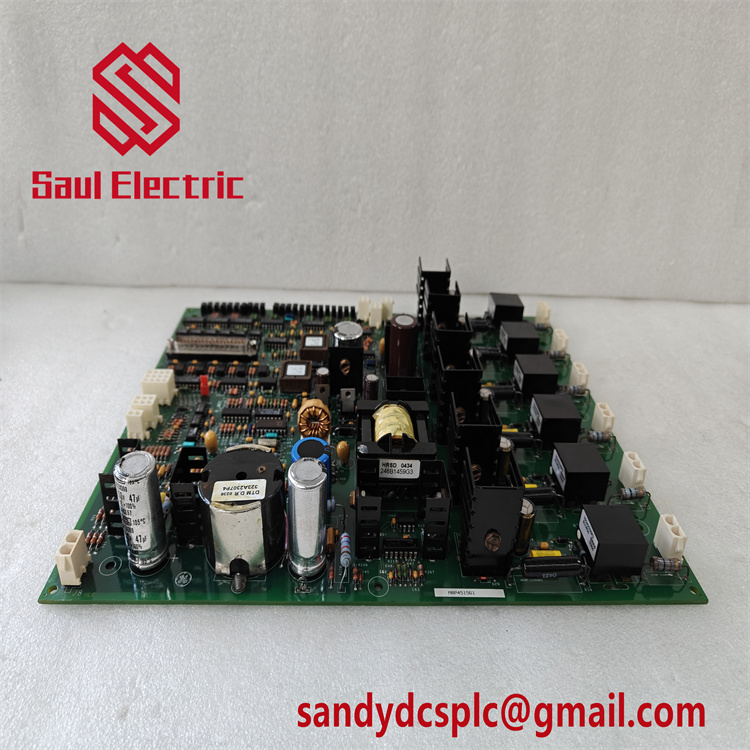

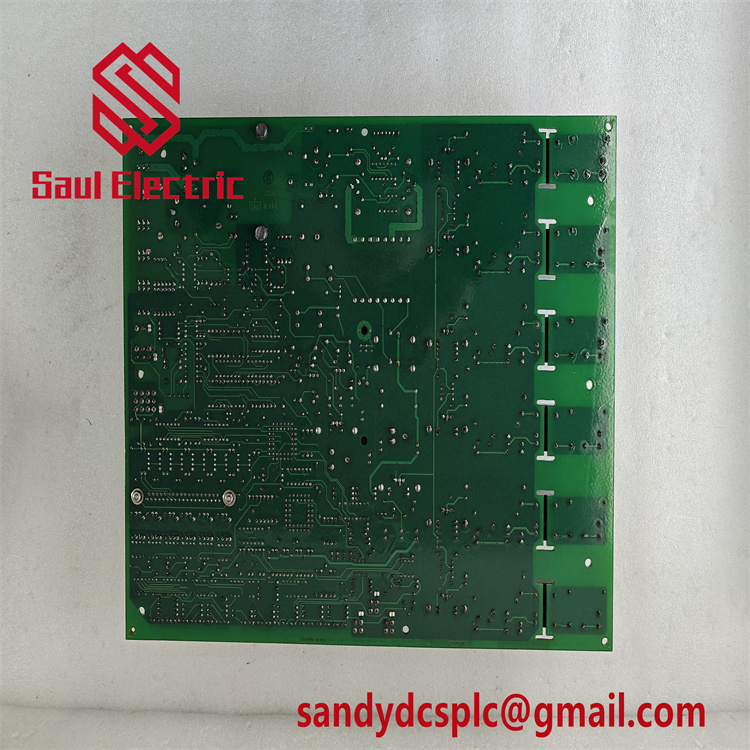

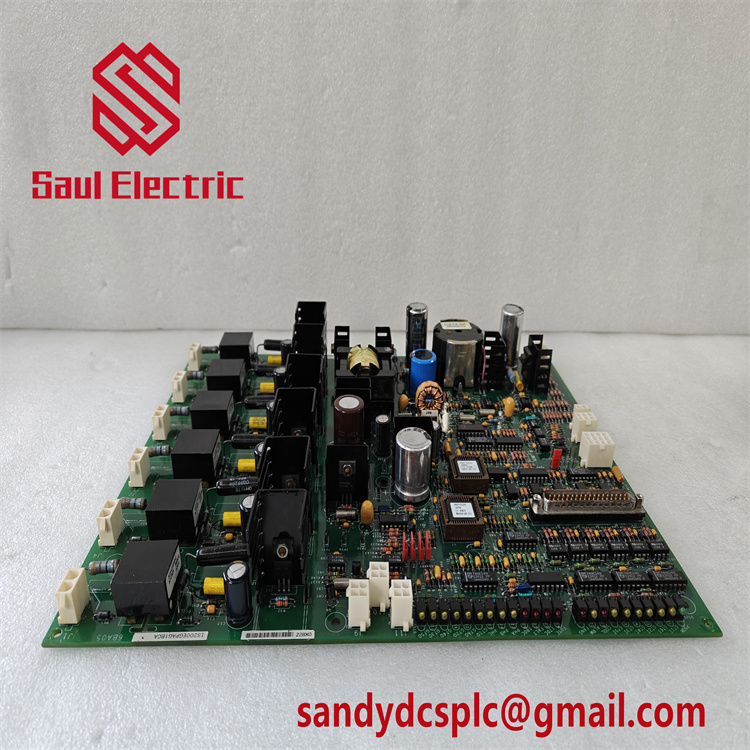

GE IS201SRTDH2A is a high-reliability RTD (Resistance Temperature Detector) terminal board designed by General Electric for the Mark VIe distributed control system. It specializes in processing temperature signals from RTD sensors in hazardous industrial environments, such as oil refineries, power plants, and chemical processing facilities. The module integrates eight RTD input channels with advanced signal conditioning, ensuring ±0.1% measurement accuracy for critical temperature monitoring. Its robust design includes conformal coating for corrosion and dust resistance, meeting Class I/Division 1 hazardous location certifications. GE IS201SRTDH2A supports seamless integration with Mark VIe I/O packs (e.g., IS221PRTDH1B) via Euro-style high-density connectors, enabling real-time data transmission over Ethernet networks. With a compact footprint optimized for DIN rail mounting, it reduces cabinet space while enhancing system resilience in extreme conditions (-40°C to 70°C) .

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS201SRTDH2A |

| Manufacturer | GE Digital |

| Product Type | RTD Terminal Board |

| Input Channels | 8 RTD inputs (3-wire/4-wire) |

| Compatibility | IS221PRTDH1B I/O pack, Mark VIe systems |

| Communication | Modbus TCP/IP via RJ45 Ethernet |

| Power Supply | 24V DC ±10% |

| Operating Temperature | -40°C to 70°C |

| Hazardous Certification | Class I/Division 1 (ATEX/IECEx equivalent) |

| Dimensions | 150mm × 90mm × 30mm (est.) |

| Weight | 0.5kg (est.) |

| Installation | DIN rail or flat surface |

| Signal Accuracy | ±0.1% FS (Full Scale) . |

Main Features and Advantages

Hazardous Environment Resilience: GE IS201SRTDH2A features conformal coating and IP65-rated encapsulation, protecting against chemical splashes, humidity, and explosive atmospheres—critical for oil/gas platforms and chemical plants .

Precision Diagnostics: Integrated ID chips enable automatic hardware recognition by I/O processors, reducing configuration errors. Real-time fault detection (e.g., RTD open-circuit alerts) minimizes unplanned downtime .

Modular Scalability: Direct compatibility with IS221PRTDH1B and other Mark VIe I/O packs allows flexible system expansion. Redundant Ethernet ports ensure continuous data flow for high-availability applications .

Application Fields

- Power Generation: Monitors turbine bearing temperatures and coolant systems in gas/steam power plants, preventing overheating failures .

- Oil & Gas: Deployed on offshore rigs for compressor temperature safety interlocks, ensuring operational integrity in methane-rich environments .

- Industrial Automation: Integrates with DCS/PLC systems (e.g., Mark VIe) for precise furnace or reactor temperature control in metallurgy and chemical processing .

Related Products

IS200TBAIH1CDD – Analog Input Terminal Board

GE IS200JPDFGIADD Processing Module(XIONGBA) | XIONGBA

IS200TRPGH2BDD – Primary Gas Turbine Trip Output Board

PPD513A25-111615 3BHE039724R2565

Installation and Maintenance

Installation Preparation: Mount GE IS201SRTDH2A on DIN rails using UL-certified clamps; verify ground resistance ≤1Ω before power-up. Route RTD cables via shielded conduits to minimize EMI interference .

Maintenance Recommendations: Quarterly calibration checks for RTD inputs; inspect conformal coating integrity annually. Use GE QuickCal software for automated drift compensation .

Product Assurance

GE IS201SRTDH2A includes a 12-month global warranty covering material defects. Lifetime technical support provides firmware updates and emergency replacement within 72 hours. All units undergo 96-hour burn-in testing, achieving MTBF >150,000 hours .

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com