Description

Many products are not yet available—feel free to contact us for more options.

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Product Overview

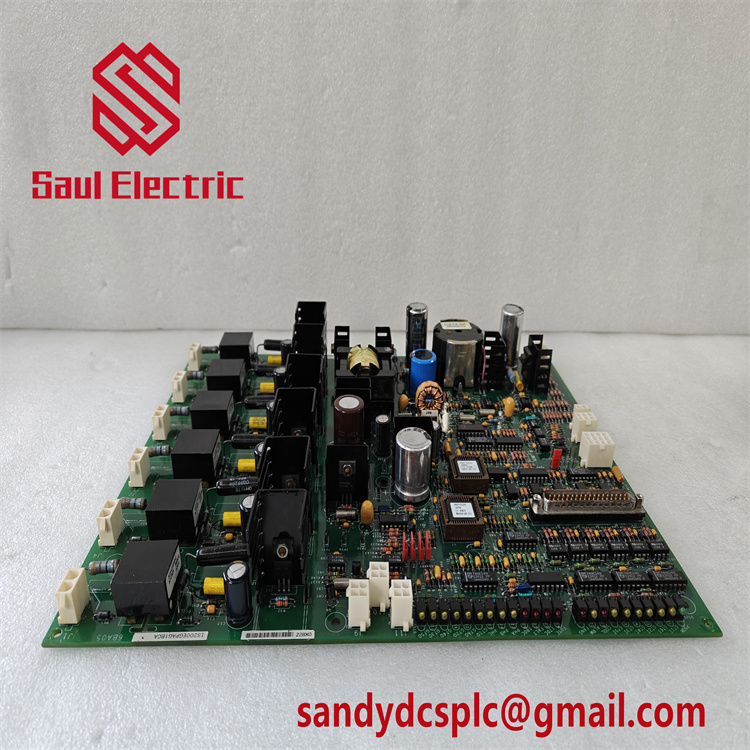

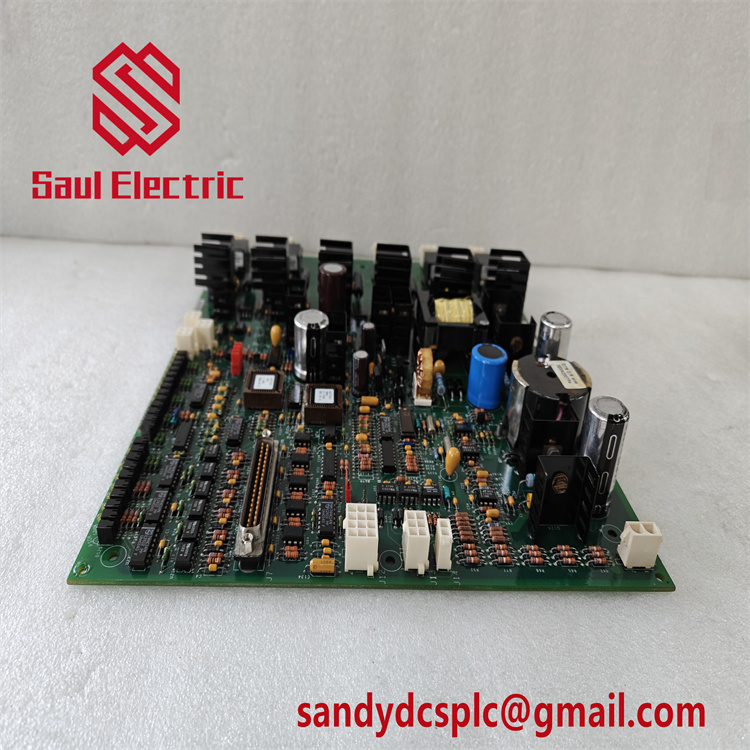

The GE IS201SRTDH1A is a high-precision Resistance Temperature Detector (RTD) input module engineered for critical industrial temperature monitoring within GE’s Mark VIeS safety control system. Designed to interface with platinum RTD sensors (PT100, PT500, PT1000), this module delivers 8 isolated channels for measuring temperatures ranging from -200°C to +850°C with ±0.1% accuracy. Ideal for applications where thermal stability is non-negotiable, such as gas turbine protection, chemical reactor control, and offshore process plants, the GE IS201SRTDH1A ensures real-time data integrity while adhering to SIL 3 (IEC 61508) safety standards.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS201SRTDH1A |

| Manufacturer | General Electric |

| Product Type | Safety RTD Input Module (Fail-Safe Digital) |

| Input Type | 3-wire or 4-wire platinum RTD (PT100, PT500, PT1000) |

| I/O Channels | 8 isolated channels |

| Accuracy | ±0.1% of reading (at 25°C) |

| Resolution | 0.1°C |

| Communication Protocol | VME Bus (32-bit/33 MHz) |

| Power Supply | 24V DC ±10% (reverse polarity protected) |

| Operating Temperature | -40°C to +70°C (-40°F to +158°F) |

| Physical Dimensions | 150mm x 100mm x 40mm (W x H x D) |

| Weight | 350g |

| Interface Type | 50-pin VME connector, removable terminal blocks |

| Redundancy Support | Triple Modular Redundancy (TMR) |

| Compliance | SIL 3 (IEC 61508), ATEX Zone 2, IEC 61400-25 (wind turbine certification) |

Key Features and Advantages

Application Areas

- Power Generation: Monitoring turbine blade temperatures during start-up/shutdown cycles to prevent overheating, and ensuring optimal performance of steam generators.

- Oil & Gas: Detecting temperature anomalies in subsea manifolds and pipeline flow, ensuring safe operation of wellhead control panels and FPSOs.

- Chemical Processing: Maintaining precise reactor temperature profiles to control exothermic reactions, critical for preventing runaway processes.

- Renewables: Optimizing wind turbine gearbox cooling systems through real-time thermal analysis, enhancing energy efficiency and reducing downtime.

- Water/Wastewater: Monitoring pump and blower temperatures in treatment plants to prevent mechanical failures and ensure regulatory compliance.

Related Products

IS200TBAIH1CDD – Analog Input Terminal Board

ABB IGCT 5SHY4045L0006 3BHB030310R0001 Module

ABB PPD539A102 3BHE039770R0102

GE IS200JPDFGIADD Processing Module(XIONGBA) | XIONGBA

IS200TRPGH2BDD – Primary Gas Turbine Trip Output Board

Installation and Maintenance

Prior to installing the GE IS201SRTDH1A, ensure the control system is powered down and ESD precautions are followed. Mount the module in a VME rack with proper grounding and EMI shielding. Connect RTD sensors to the removable terminal blocks, verifying wiring polarity and torque specifications. Use 50-pin ribbon cables to link the GE IS201SRTDH1A to the safety controller, following the wiring diagram in the GE technical manual. Configure TMR settings and temperature thresholds via ControlST software, validating redundancy paths for safety-critical applications.

Regularly inspect terminal blocks for corrosion, particularly in high-humidity environments, and secure loose connections. Perform quarterly system diagnostics using ControlST to verify channel integrity and redundancy status. Replace worn terminal blocks every 5 years or as per OEM guidelines. Store spare modules in anti-static packaging to prevent ESD damage. For SIL 3 applications, conduct annual functional safety tests to ensure compliance with IEC 61508 standards.

Product Assurance

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com