Description

Many products are not yet available—feel free to contact us for more options.

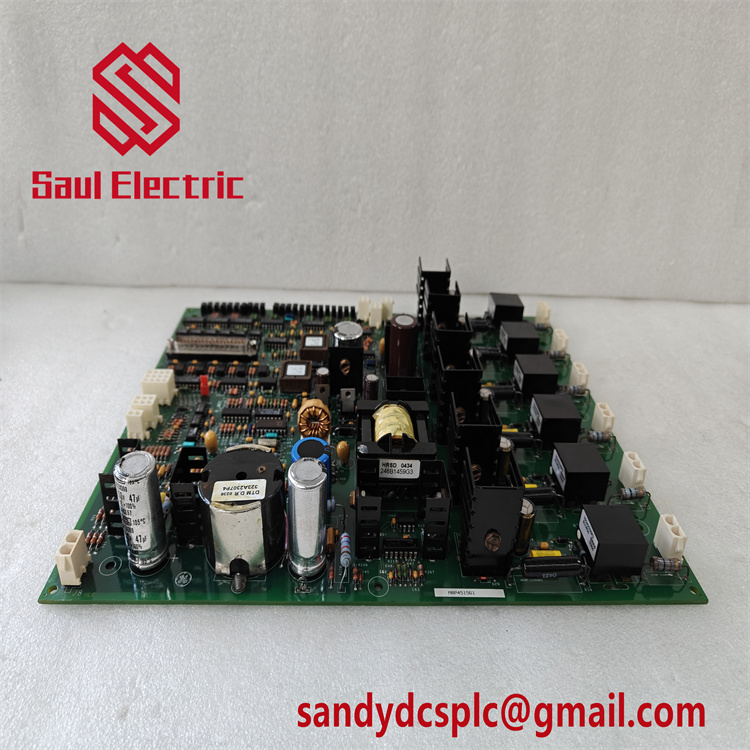

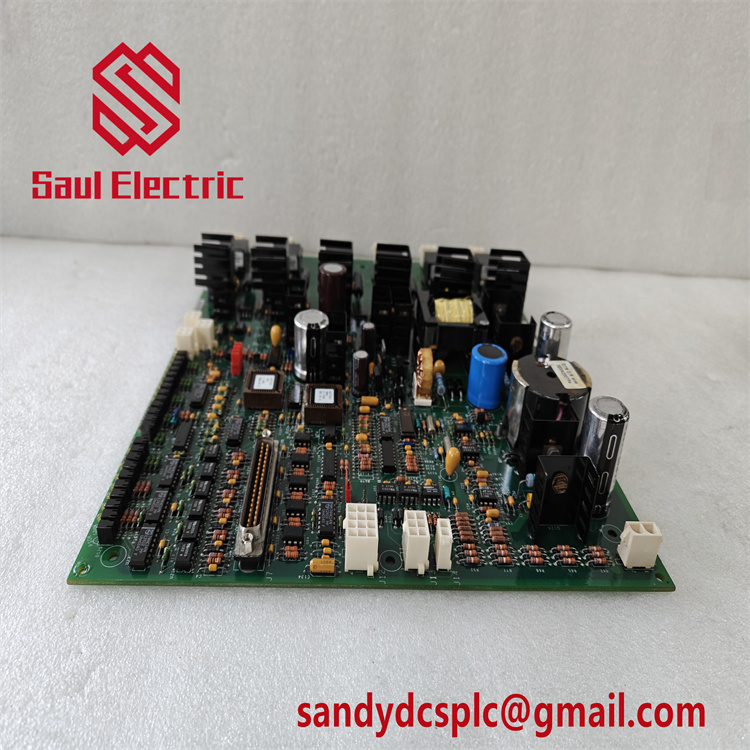

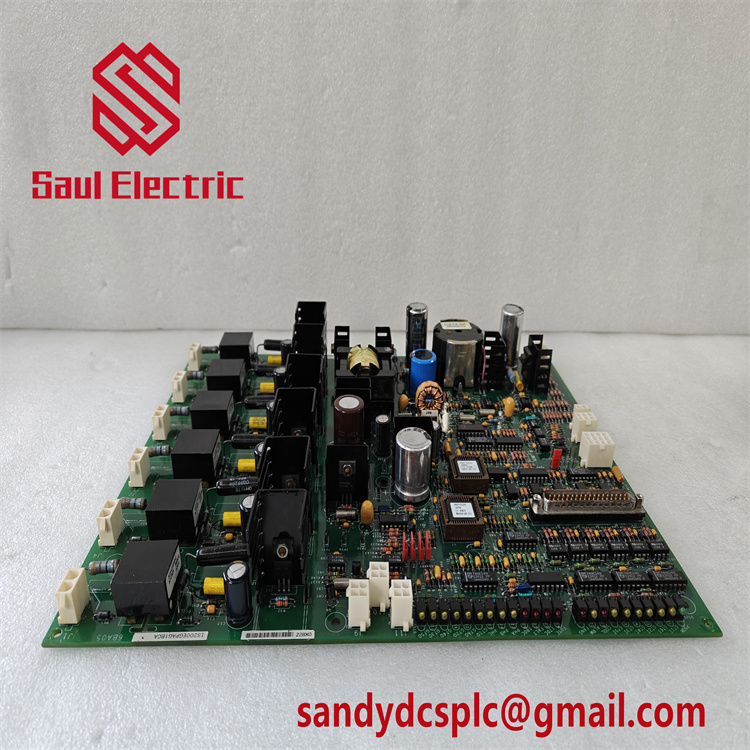

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Product Overview

The GE IS200WREAH1A is a high-performance wind energy application control module designed for integration within GE’s Mark VIE distributed control system (DCS), specifically optimized for wind turbine management. As a critical component of the Speedtronic platform, this module serves as a centralized interface for monitoring and controlling turbine operations, including pitch control, yaw alignment, and grid synchronization. The GE IS200WREAH1A supports real-time data acquisition from sensors (e.g., anemometers, vibration probes) and actuators (e.g., servo motors), ensuring precise coordination between mechanical and electrical subsystems to maximize energy production while minimizing downtime.

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS200WREAH1A |

| Manufacturer | General Electric |

| Product Type | Wind Energy Application Control Module |

| Communication Protocols | Modbus TCP/IP, Profibus DP, CANopen |

| I/O Channels | 16 digital I/O, 8 analog I/O (0-20mA/0-10V) |

| Power Supply | 24V DC ±10% |

| Operating Temperature | -30°C to +65°C (-22°F to +149°F) |

| Physical Dimensions | 150mm x 100mm x 40mm (W x H x D) |

| Weight | 350g |

| Interface Type | Dual-port Ethernet, removable terminal blocks |

| Redundancy Support | Hot-swappable dual Ethernet ports |

| EMI Protection | Built-in surge protection and grounding isolation |

| Compliance | CE, UL 508A, IEC 61400-25 |

Wind-Specific Control Logic: The GE IS200WREAH1A incorporates pre-programmed algorithms for pitch angle optimization, yaw correction, and grid synchronization, tailored to wind turbine dynamics. This reduces reliance on external PLCs and simplifies system architecture.

Redundant Network Architecture: With dual-port Ethernet connectivity, the module ensures continuous operation in mission-critical scenarios. Redundant configurations (e.g., ring topology) eliminate single points of failure, critical for offshore installations where repair access is limited.

Rugged Industrial Design: Rated for extreme environmental conditions, the GE IS200WREAH1A features conformal coating to protect against salt mist, dust, and UV radiation. Its robust construction meets IEC 61400-25 standards for wind turbine communication systems.

Flexible I/O Integration: The 16 digital I/O and 8 analog channels support diverse field devices, including servo drives, encoders, and temperature sensors. Removable terminal blocks simplify wiring changes during maintenance, reducing mean time to repair (MTTR).

Centralized Diagnostics: Integrated with ControlST software, the module provides real-time insights into turbine health, including vibration analysis and power output metrics. This proactive approach enables predictive maintenance, extending equipment lifespan by up to 20%.

The GE IS200WREAH1A excels in wind energy and related industries requiring precision turbine control:

- Wind Power Generation: Deployed in horizontal-axis wind turbines (HAWTs) for pitch control, yaw alignment, and grid synchronization, optimizing energy capture across varying wind speeds.

- Grid Integration: Supports seamless connection to utility grids by managing reactive power compensation and voltage regulation, ensuring compliance with grid codes (e.g., FERC Order 661-A).

- Condition Monitoring: Integrates with vibration analysis systems to detect early signs of bearing wear or gearbox misalignment, reducing unplanned downtime in offshore wind farms.

- Retrofit Projects: Backward-compatible with GE’s Mark V and Mark VI systems, the GE IS200WREAH1A facilitates modernization of legacy wind turbines without replacing entire control systems.

By combining advanced control logic with rugged hardware, the GE IS200WREAH1A future-proofs wind energy assets while maximizing return on investment.

ABB PPD513 | AC800PEC | excitation controller | PP D513

PPD513A25-111615 3BHE039724R2565

IS200TBAIH1CDD – Analog Input Terminal Board

GE IS200JPDFGIADD Processing Module(XIONGBA) | XIONGBA

IS200TRPGH2BDD – Primary Gas Turbine Trip Output Board

Installation Preparation:

Prior to installing the GE IS200WREAH1A, ensure the turbine control system is powered down and ESD precautions are followed. Mount the module in a VME rack with proper grounding and EMI shielding. Connect dual Ethernet cables to the turbine’s supervisory control system and wire field devices (e.g., pitch sensors) to the terminal blocks, following the wiring diagram in the GE technical manual. Configure communication parameters (e.g., IP addresses, protocol settings) using ControlST software, ensuring synchronization with the turbine’s PLC.

Regularly inspect terminal blocks for corrosion and secure wiring connections, particularly in offshore environments. Perform quarterly system diagnostics using ControlST to verify network latency and I/O channel integrity. Replace worn terminal blocks every 5 years or as per OEM guidelines. Store spare modules in anti-static packaging to prevent ESD damage. For analog channels, recalibrate sensors annually to maintain accuracy in wind speed and direction measurements.

The GE IS200WREAH1A is backed by a 1-year warranty covering defects in materials and workmanship. GE provides comprehensive technical support, including firmware updates and remote troubleshooting, to ensure optimal performance. With spot inventory availability and a 3-day delivery window post-payment, customers benefit from rapid deployment and minimized downtime. GE’s global network of certified service centers guarantees prompt repairs and refurbishment, reinforcing the module’s long-term reliability in wind energy applications.

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com