Description

Many products are not yet available—feel free to contact us for more options.

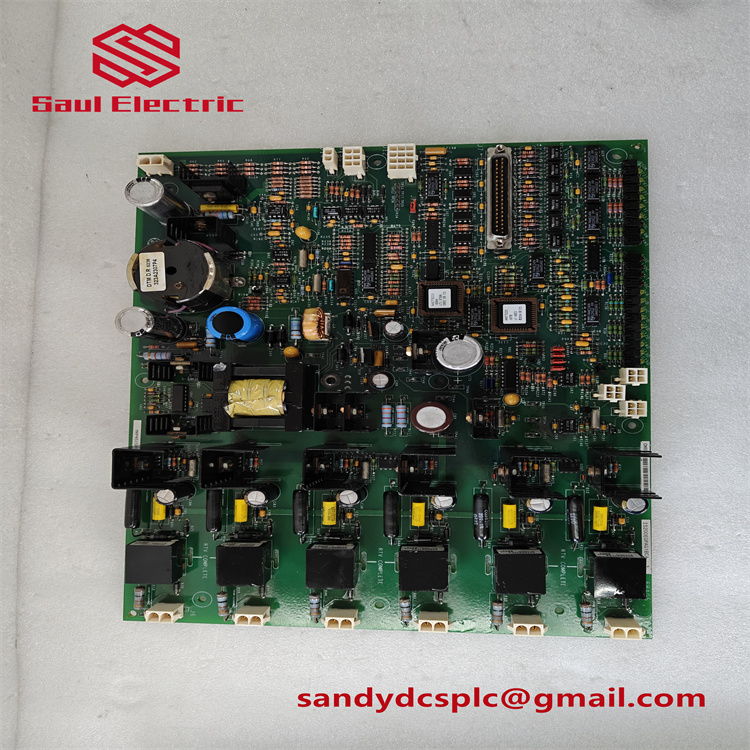

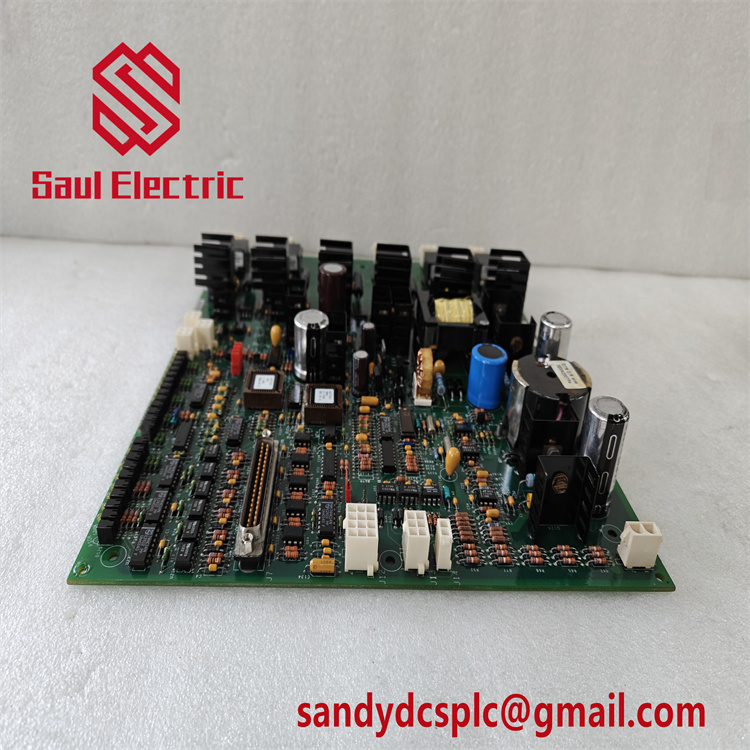

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Product Overview

The GE IS200TVBAS2A is a high-performance vibration input terminal board designed for critical industrial applications, specifically integrated within GE’s Mark VIE distributed control system (DCS). As a core component of the Speedtronic gas turbine control architecture, this module serves as a vital interface between vibration sensors and the control system, ensuring accurate signal conditioning and reliable data transmission. The GE IS200TVBAS2A supports up to 14 channels of vibration monitoring, accommodating Bently Nevada Proximitor®, Seismic®, and Accelerometer® probes, making it ideal for rotating equipment health assessment in power generation, oil & gas, and heavy manufacturing sectors.

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS200TVBAS2A |

| Manufacturer | General Electric |

| Product Type | Vibration Input Terminal Board |

| Input Channels | 14 |

| Sensor Compatibility | Bently Nevada Proximitor®, Seismic®, Velomitor®, Accelerometer® probes |

| Communication Protocol | VME Bus |

| Power Supply | 24V DC ±10% |

| Operating Temperature | -30°C to +65°C (-22°F to +149°F) |

| Physical Dimensions | 100mm x 50mm x 20mm (W x H x D) |

| Weight | 100g |

| Interface Type | 37-pin connector (VME), BNC connectors for external monitoring |

| Redundancy Support | Simplex, dual, and TMR configurations |

| EMI Protection | Built-in signal suppression and grounding isolation |

Rugged Signal Conditioning: The GE IS200TVBAS2A incorporates advanced signal conditioning circuitry to filter noise and amplify weak vibration signals, ensuring accurate measurements even in high-interference environments. Its dual-channel design with pull-up bias detection enables open-circuit fault identification, enhancing diagnostic capabilities.

Modular Redundancy: With support for TMR configurations, the terminal board ensures continuous operation by distributing signals across three independent I/O packs. This redundancy minimizes single points of failure, critical for applications where downtime is costly.

Flexible Integration: The BNC connectors facilitate quick integration with third-party vibration analysis tools, such as Bently Nevada’s 3500 system, enabling remote data logging and predictive maintenance. The 37-pin VME interface guarantees seamless compatibility with GE’s Mark VIE controllers.

Wide Environmental Tolerance: Rated for extreme temperatures and humidity, the GE IS200TVBAS2A performs reliably in offshore platforms, power plants, and other harsh industrial settings. Its surface-mount components and conformal coating protect against dust, moisture, and chemical exposure.

Efficient Maintenance: The removable terminal blocks simplify wiring changes, while the infrared transceiver supports low-level diagnostics without system shutdown. This reduces mean time to repair (MTTR) and enhances operational efficiency.

The GE IS200TVBAS2A excels in mission-critical industries where rotating equipment health monitoring is paramount:

- Power Generation: Deployed in gas and steam turbines to monitor shaft vibration, eccentricity, and axial position, ensuring compliance with ISO 10816 standards.

- Oil & Gas: Integral to compressor trains and pumps, providing real-time data for condition-based maintenance (CBM) strategies.

- Heavy Manufacturing: Used in high-speed rotating machinery, such as industrial motors and gearboxes, to detect early signs of wear or misalignment.

- Water/Wastewater: Supports vibration analysis of pumps and blowers in treatment plants, optimizing energy consumption and extending equipment lifespan.

By enabling proactive maintenance, the GE IS200TVBAS2A reduces unplanned outages, lowers repair costs, and extends asset longevity.

IS200TBAIH1CDD – Analog Input Terminal Board

GE IS200JPDFGIADD Processing Module(XIONGBA) | XIONGBA

IS200TRPGH2BDD – Primary Gas Turbine Trip Output Board

PPD513A25-111615 3BHE039724R2565

Installation Preparation:

Prior to installing the GE IS220TVBAS2A, ensure the power is disconnected and static-sensitive handling procedures are followed. The module should be mounted in a VME rack with proper grounding and EMI shielding. Connect vibration sensors to the terminal blocks, ensuring correct polarity and torque specifications. Use 37-pin ribbon cables to link the GE IS200TVBAS2A to the PVIB/YVIB I/O packs, following the wiring diagram provided in the GE technical manual.

Regularly inspect BNC connectors for corrosion and secure wiring connections. Perform annual system diagnostics using ControlST software to verify signal integrity and redundancy status. Replace worn terminal blocks every 5 years or as per OEM guidelines. Store spare modules in anti-static packaging to prevent electrostatic discharge (ESD) damage.

The GE IS200TVBAS2A is backed by a 1-year warranty covering defects in materials and workmanship. GE provides comprehensive technical support, including firmware updates and troubleshooting guidance, to ensure optimal performance. With spot inventory availability and a 3-day delivery window post-payment, customers benefit from rapid deployment and minimized downtime. GE’s global network of certified service centers guarantees prompt repairs and refurbishment, reinforcing the module’s long-term reliability.

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com