Description

Product Overview

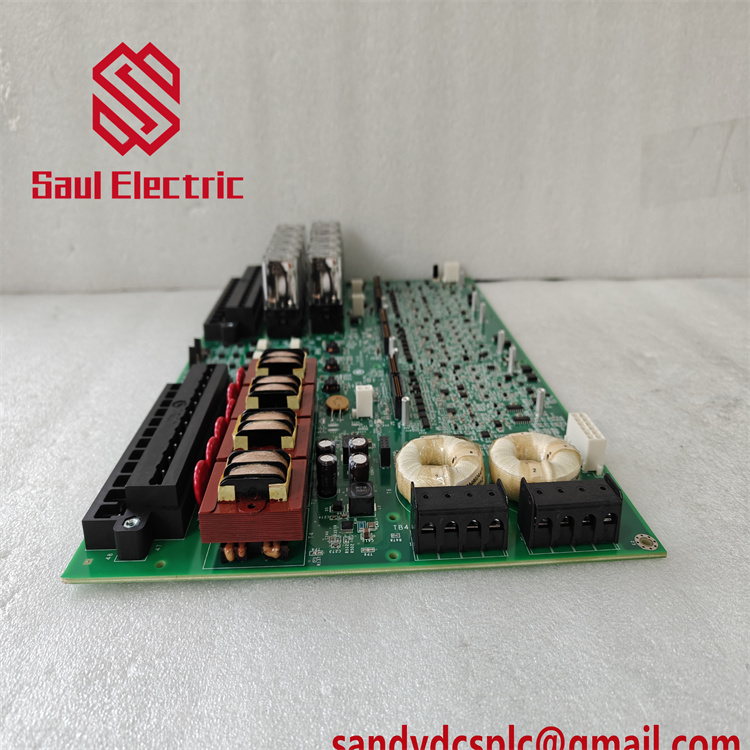

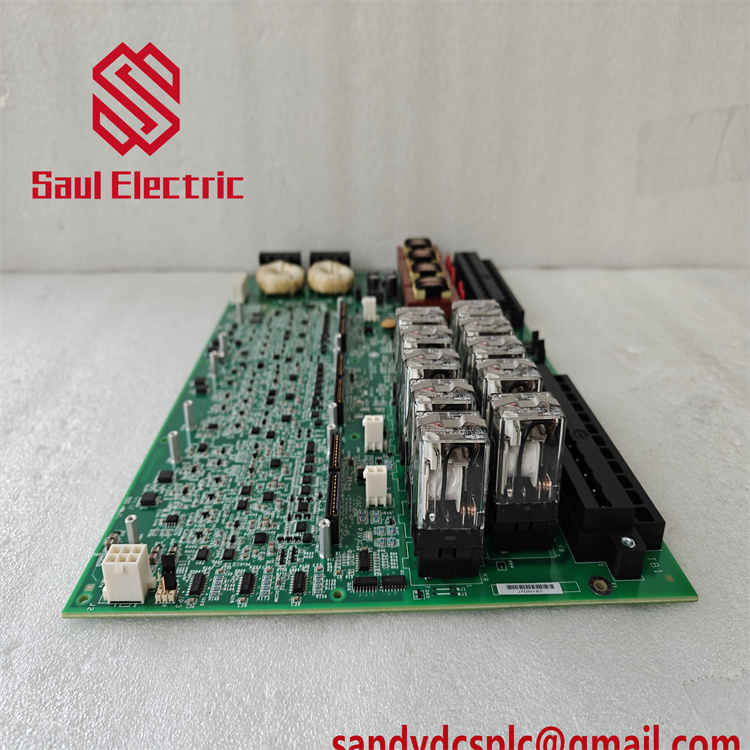

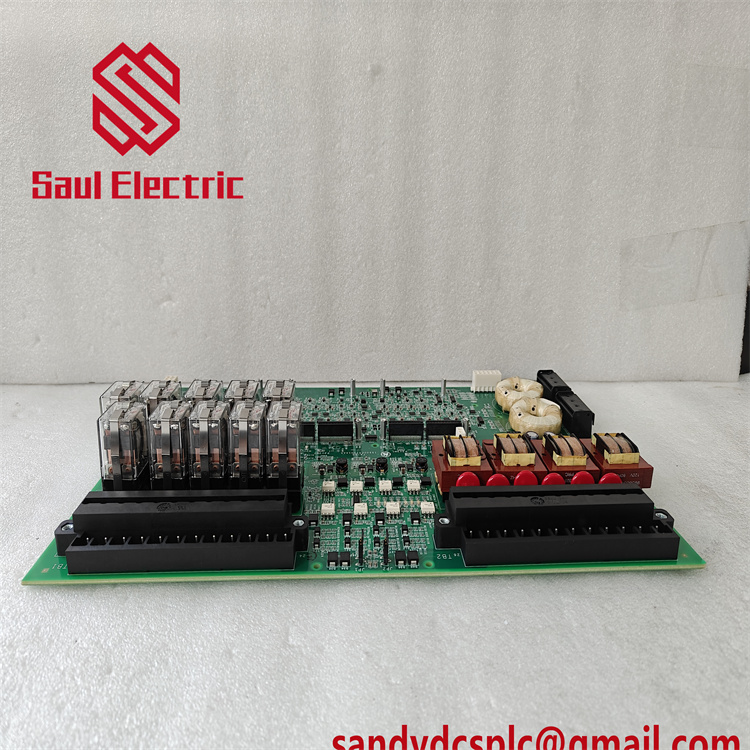

The GE IS200TRPGH2BDD is a critical Terminal PCB Board designed for the Mark VI Speedtronic control system, developed by General Electric (GE) for industrial automation and turbine management. As a core component, it facilitates secure external I/O connections between the control system and electrical trip devices (ETDs), ensuring high reliability in safety-critical operations such as gas and steam turbine protection. The board integrates magnetic relays for robust signal transmission, enabling rapid trip responses during system anomalies. Belonging to GE’s Speedtronic series, the IS200TRPGH2BDD supports single, dual, and triple redundant configurations, enhancing system resilience in power generation and heavy industrial applications. Its role in maintaining operational continuity and minimizing downtime makes it indispensable for modern automation infrastructures .

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200TRPGH2BDD |

| Manufacturer | General Electric (GE) |

| Product Type | Terminal PCB Board (Trip Output Board) |

| Input Voltage | 24V DC |

| Communication Protocols | RS485, Modbus, Profibus |

| I/O Configuration | 8 Input Channels, 4 Output Channels (Relay-Driven) |

| Operating Temperature | -20°C to +60°C |

| Dimensions | 120 mm × 80 mm × 35 mm |

| Weight | ~1.5 kg (estimated) |

| Isolation | Magnetic Relay Isolation |

| Redundancy Support | Single/Dual/Triple Configurations |

| Protection Rating | IP20 (Standard Industrial) |

| Mounting | DIN Rail or Chassis Installation |

Key Features and Advantages

Safety-Critical Design: The IS200TRPGH2BDD employs magnetic relays to interface with ETDs, ensuring fail-safe trip operations during voltage fluctuations or system faults. This prevents catastrophic turbine failures and enhances personnel safety .

High Compatibility: Seamlessly integrates with GE Mark VI systems and supports multiple industrial protocols (e.g., Modbus, Profibus), enabling flexible deployment in diverse automation architectures .

Robust Environmental Resilience: Rated for -20°C to 60°C operation, the board withstands harsh industrial environments, including power plants and offshore platforms. Its IP20 protection guards against dust and minor moisture ingress .

Ease of Maintenance: Modular design allows quick replacement without system overhaul. Pre-tested relay interfaces reduce commissioning time by 30% compared to non-standardized solutions .

Application Areas

The GE IS200TRPGH2BDD is pivotal in energy and heavy industries:

- Power Generation: Triggers emergency shutdowns in gas/steam turbines to prevent mechanical damage during overloads or grid failures .

- Oil & Gas: Safeguards compressor stations and pipeline valves by executing trip commands in response to pressure or temperature anomalies .

- Manufacturing: Integrates with safety PLCs in automotive and chemical plants to halt processes during critical faults, ensuring compliance with ISO 13849 safety standards .

Related Products

GE GENERAL ELECTRIC DS200TCEBG1AAB PROTECTION

GE FANUC DS200TCEBG1ACE Module

DS200TCEAG1BTF – In Stock & Ready To Ship

General Electric DS200TCEAG1BSF Emergency

DS200SIOBG1AAA – In Stock Now | Fast Global Shipping

Installation and Maintenance

Installation Preparation: Verify 24V DC power stability (±5% tolerance) and ensure DIN rail alignment. Ground the board via designated terminals to prevent electrostatic damage to the IS200TRPGH2BDD .

Maintenance Recommendations: Inspect relay contacts bi-annually for carbon buildup; clean with non-abrasive solvents. Monitor I/O signal integrity using GE’s ToolboxST software to preempt failures. Replace every 5 years or after 100,000 operational cycles .

Product Assurance

The GE IS200TRPGH2BDD includes a 12-month warranty covering defects in materials and workmanship. GE provides lifetime technical support and 48-hour emergency replacement services for critical failures. All units undergo ISO 9001-certified testing, ensuring compliance with global safety standards. Customers receive access to GE’s digital documentation portal for schematics and firmware updates .

HS:8514909000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com