Description

Many products are not yet available—feel free to contact us for more options.

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Product Overview

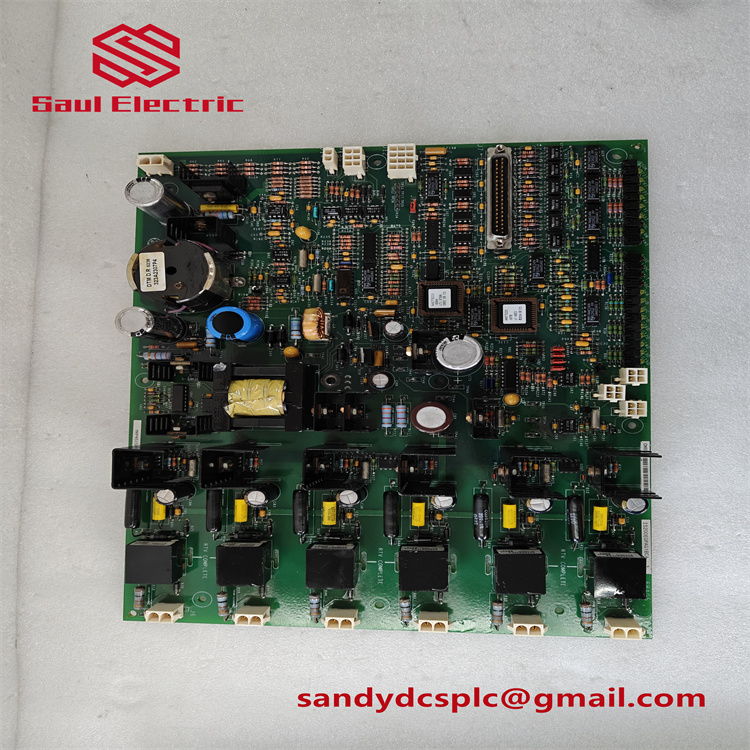

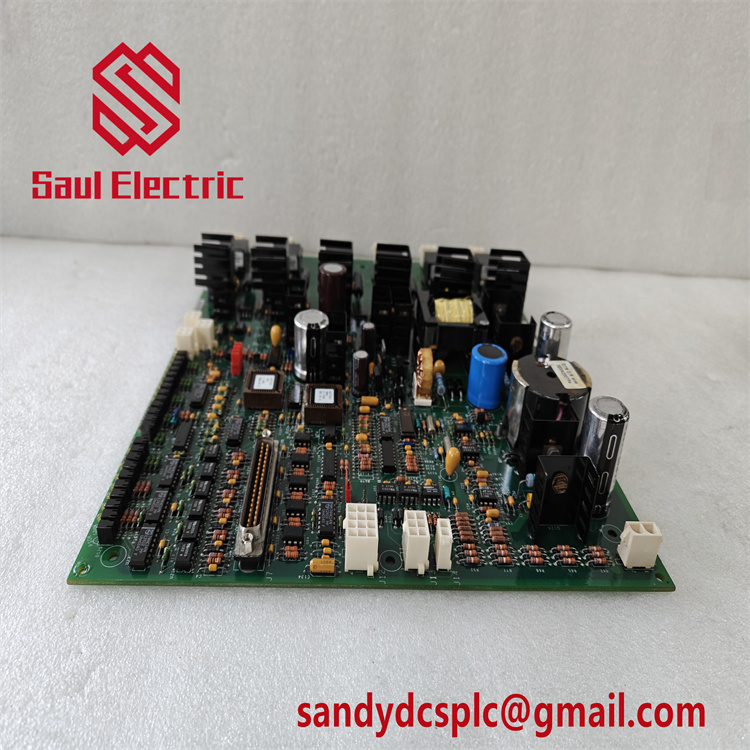

The GE IS200TRPAH1A is a high-reliability primary trip terminal board engineered for aeroderivative gas and steam turbine control systems, serving as a core component of GE’s Mark VIe platform. Designed to execute critical turbine protection logic, this board integrates with PTUR/YTUR I/O packs and TTUR terminal boards to monitor turbine health parameters and trigger emergency shutdowns (ESD) when 异常 conditions are detected. Its dual operational modes—direct I/O pack integration or TTUR-based TMR configurations—provide flexibility for both simplex and redundant system designs, ensuring fail-safe actuation in power generation, oil & gas, and industrial process applications.

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS200TRPAH1A |

| Manufacturer | General Electric |

| Product Type | Primary Trip Terminal Board |

| Input Voltage | 24–125 V DC (voltage detection) |

| Speed Input | -15–140 V DC (passive pulse rate) |

| E-Stop Input | 18–140 V DC |

| Output Voltage | 24 V DC nominal (28 V DC max) |

| Trip Relay Configuration | Dual contact-voted outputs |

| Voltage Detection Circuits | 4 channels (24–125 V DC) |

| Pulse Rate Sensors | 6 passive inputs (3 shafts × 2 sensors) |

| Communication Protocol | IONET (Mark VIe standard) |

| Operating Temperature | -30°C to +65°C |

| Mounting Type | Panel-mounted with DIN rail compatibility |

| Weight | 1.2 kg (estimated) |

Dual-Mode Trip Logic: The GE IS200TRPAH1A supports two configurations:

- TTUR-TMR Mode: Connected via TTUR terminal boards, it provides three independent relay banks (R/S/T) that vote on trip signals, ensuring redundancy for critical ESD systems.

- Direct I/O Mode: Directly interfacing with PTUR/YTUR packs, it offers simplex actuation for non-safety-critical applications, reducing hardware complexity.

- Four voltage detection circuits continuously monitor trip strings for anomalies like undervoltage or open circuits, with thresholds configurable via GE’s Proficy software.

- Six passive pulse rate inputs analyze turbine speed using toothed wheel sensors, supporting overspeed protection up to 115% of rated speed.

The GE IS200TRPAH1A excels in high-risk turbine applications requiring rapid, reliable trip logic:

- Power Generation: Monitors gas turbine fuel systems, triggering shutdowns during flameout or compressor surge events. Its voltage detection capability ensures compliance with API 670 vibration monitoring standards.

- Oil & Gas: Integrates with BOP (blowout preventer) systems on offshore rigs, providing redundant actuation for hydraulic control valves. The board’s wide input voltage range supports legacy 125 V DC control systems.

- Industrial Process: Manages steam turbine-driven pumps in chemical plants, using pulse rate inputs to detect shaft displacement and prevent catastrophic seal failures.

IS200TBAIH1CDD – Analog Input Terminal Board

PPD513A25-111615 3BHE039724R2565

GE IS200JPDFGIADD Processing Module(XIONGBA) | XIONGBA

IS200TRPGH2BDD – Primary Gas Turbine Trip Output Board

Pre-Installation Preparation:

- Verify power supply compatibility and ground connections using GE’s Mark VIe wiring diagram (GEH-6721).

- Configure jumpers JP1/JP2 to fan out pulse rate signals to PTUR/YTUR packs in TMR mode.

- Perform quarterly voltage detection circuit calibration using GE’s Proficy software.

- Replace relays every 5 years or after 500,000 operations to maintain contact integrity.

- Inspect terminal block torque annually to prevent loose connections in high-vibration environments.

GE guarantees the IS200TRPAH1A with a 2-year warranty for new/repaired units and a 3-year warranty for remanufactured units, covering material defects and workmanship. The board undergoes rigorous testing to meet UL 508 and IEC 61131-2 standards, ensuring compliance with global safety protocols. GE’s 24/7 technical support network provides rapid troubleshooting and replacement services, minimizing downtime in critical applications.

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com