Description

Many products are not yet available—feel free to contact us for more options.

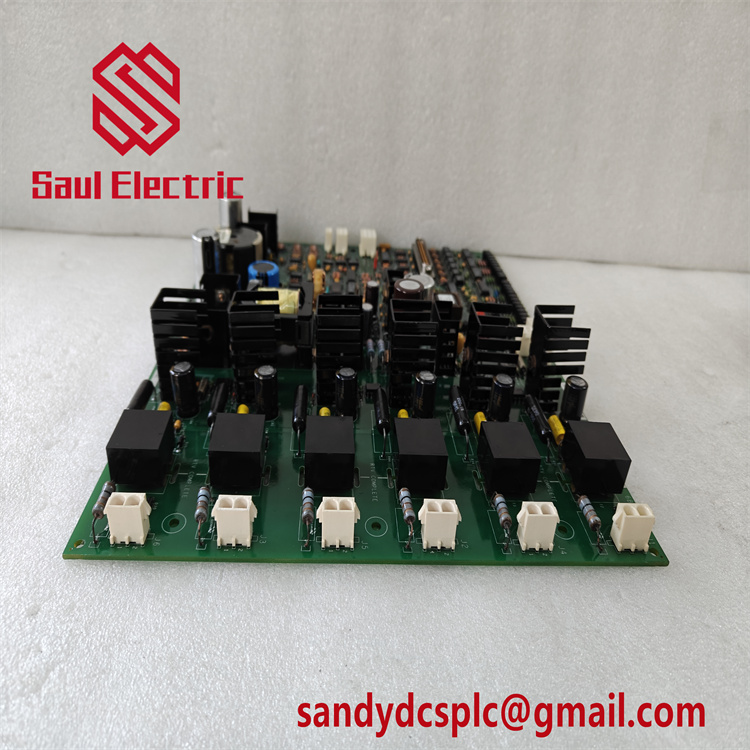

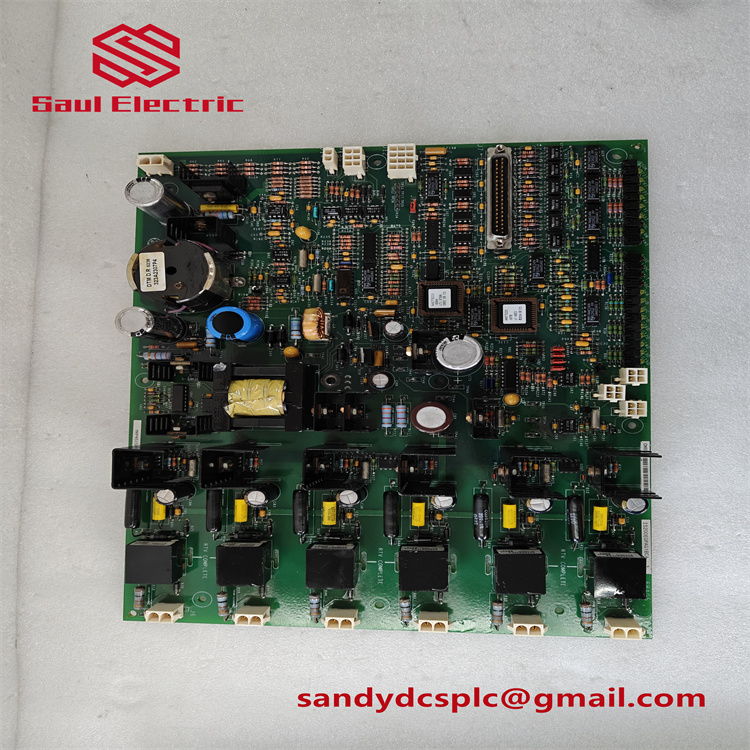

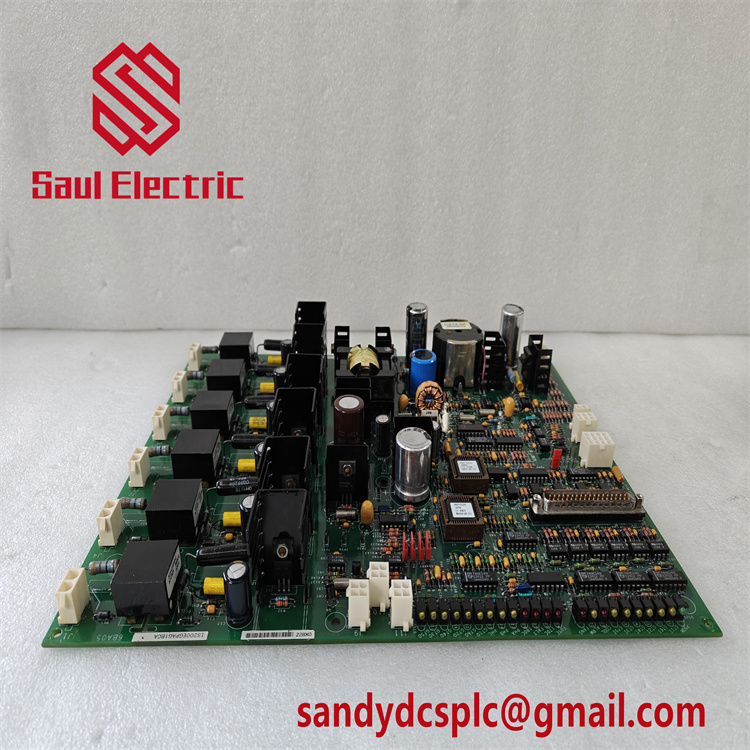

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Product Overview

The GE IS200TRLYS1F is a high-reliability relay output terminal board engineered for mission-critical turbine control systems, part of GE’s advanced Mark VIe platform. Designed with triple modular redundancy (TMR) contact voting functionality, this module ensures fail-safe operation in applications where equipment integrity and process continuity are paramount. Unlike its Form B (Normally Closed) counterparts, the GE IS200TRLYS1F features 12 contact-voted relay outputs configured as Form A (Normally Open), making it ideal for non-safety-critical systems where energization triggers protective actions.

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS200TRLYS1F |

| Manufacturer | General Electric |

| Product Type | Relay Output Terminal Board |

| Relay Configuration | 12 channels (3 TMR segments) |

| Contact Rating | 10 A @ 250 V AC/30 V DC |

| Input Voltage | 24 V DC / 115 V AC |

| Output Type | Form A (Normally Open) |

| Operating Temperature | -30°C to +65°C |

| Board Size | 150 mm (W) x 100 mm (H) |

| Weight | 0.5 kg (1.10 lbs) |

| Mounting Type | DIN rail / panel-mounted |

| Communication Protocol | IONET (Mark VIe standard) |

| Redundancy Support | Simplex/TMR |

| Diagnostic Features | Coil current monitoring |

TMR Contact Voting with Form A Output: The GE IS200TRLYS1F employs three independent relay banks (R, S, T) that vote on control signals, ensuring reliable actuation even if one segment fails. Its Form A configuration inherently supports standard actuation logic, where energization triggers protective actions, critical for non-safety-critical processes in power generation and industrial automation.

The GE IS200TRLYS1F excels in scenarios requiring reliable relay control for non-safety-critical applications:

- Power Generation: Manages auxiliary systems in gas turbines, such as lubrication pumps and cooling fans, ensuring stable operation during load shedding or grid instability. Its Form A configuration guarantees device actuation upon power restoration.

- Oil & Gas: Controls non-safety-related valves and pumps in onshore facilities, providing redundant actuation for process optimization. Ideal for applications where valve closure is not life-critical but requires consistent performance.

- Chemical Processing: Integral to batch processing systems, where precise relay switching ensures ingredient dosing accuracy and compliance with ISO 13702 standards.

- Water Treatment: Controls non-essential pumps and valves in wastewater treatment plants, maintaining operational efficiency through redundant actuation logic.

ABB IGCT 5SHY4045L0006 3BHB030310R0001 Module

IS200TBAIH1CDD – Analog Input Terminal Board

GE IS200JPDFGIADD Processing Module(XIONGBA) | XIONGBA

IS200TRPGH2BDD – Primary Gas Turbine Trip Output Board

Pre-Installation Preparation: Verify power supply compatibility and ensure proper grounding. Align the GE IS200TRLYS1F with the Mark VIe I/O rack using DIN rail brackets, securing all connectors (JR1, JS1, JT1) for TMR configurations. Conduct a continuity check to confirm proper wiring before powering up.

GE guarantees the IS200TRLYS1F with a 1-year warranty covering material defects and workmanship. The board undergoes rigorous testing to meet UL 508 and IEC 61131-2 standards, ensuring compliance with global safety protocols. GE’s 24/7 technical support network provides rapid troubleshooting and replacement services, minimizing downtime in critical applications.

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com