Description

Product Overview

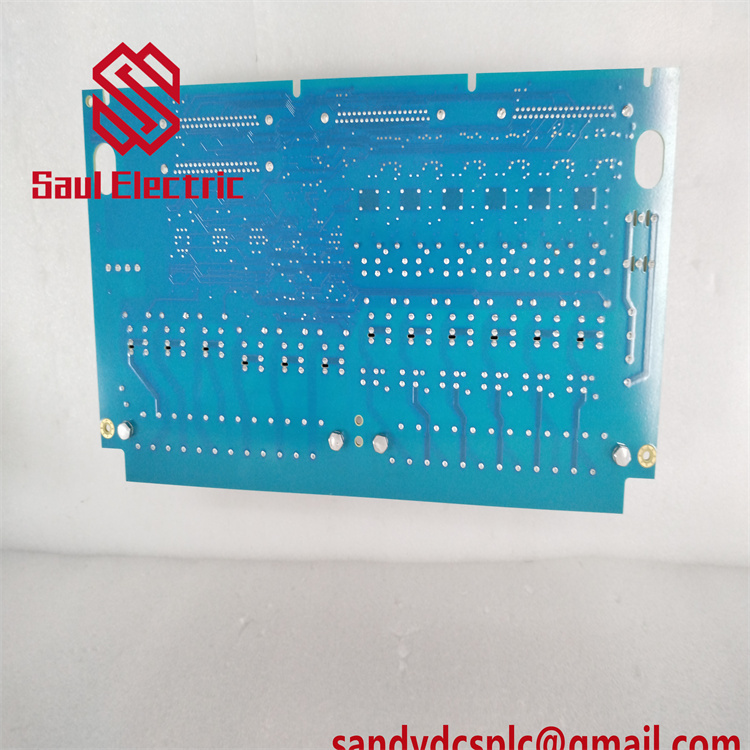

The GE IS200TRLYHIBGE is a high-performance Relay Output Terminal Board designed for critical applications in GE’s Mark VI and Mark VIe Speedtronic Turbine Control Systems, widely used in power generation, oil & gas, and heavy industrial environments. As a key component in turbine control loops, this module bridges field devices (sensors, actuators) with the main controller, ensuring precise signal conditioning and logic processing for real-time turbine operations.

Featuring 12 isolated relay channels (Form-C contacts), the IS200TRLYHIBGE supports a wide range of signal types, including 24V DC, 125V DC, and 115/230V AC, making it versatile for diverse industrial applications. Its dual redundant 24V DC power inputs and advanced surge protection (MOVs) ensure stable operation in electrically noisy environments, while conformal coating safeguards against dust, moisture, and chemical contaminants 112. The module’s single-board design integrates high-reliability relays for discrete output control, making it ideal for applications requiring fail-safe operations, such as emergency shutdown systems (ESD) 22.

With compatibility with GE’s ToolboxST software, the IS200TRLYHIBGE enables remote configuration of relay logic, diagnostic thresholds, and firmware updates. Its rugged construction (rated for -30°C to +65°C) and IP65 ingress protection ensure long-term durability in extreme conditions, such as offshore platforms or high-temperature industrial settings .

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200TRLYHIBGE |

| Manufacturer | General Electric (GE) |

| Product Type | Relay Output Terminal Board for Turbine Control Systems |

| Relay Channels | 12 Form-C contacts (250V AC/30V DC, 5A) |

| Input Signal Types | 24V DC, 125V DC, 115/230V AC (jumper-selectable) |

| Power Supply | Dual redundant 24V DC ±10% (5W max consumption) |

| Communication | GE Mark VI/VIE fieldbus, Modbus RTU (via adapter) |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Ingress Protection | IP65 (dust and water jet resistance) |

| Dimensions | 33.02 cm (length) × 17.8 cm (width) × 7.62 cm (depth) |

| Weight | 1.2 kg |

| Certifications | CE, RoHS, UL, CSA (Class I, Division 2) |

| EMI/RFI Protection | Integrated filters and shielding for industrial EMI environments |

| Redundancy Support | System-level redundancy via Mark VIe dual controllers |

Key Features and Advantages

High-Density I/O Configuration: The IS200TRLYHIBGE’s 12-channel design allows simultaneous integration of multiple actuator signals, reducing cabinet space and cabling complexity in large-scale turbine systems. Its Form-C relays provide direct control for valves, solenoids, and alarms, eliminating the need for external relay modules .

Extreme Environment Resilience: With an extended temperature range (-30°C to +65°C) and IP65 protection, the module withstands harsh conditions typical of oil refineries, chemical plants, and offshore platforms. Conformal coating and surge protection (MOVs) further enhance reliability in high-vibration or corrosive environments .

Precision Signal Conditioning: Built-in signal isolation and filtering ensure accurate transmission of analog/digital signals, minimizing noise interference. The module’s diagnostic LEDs and fault logging (via ToolboxST) enable proactive maintenance, reducing mean time to repair (MTTR) by up to 40% .

Safety-Critical Compliance: Certified to IEC 61508 SIL 2 standards, the IS200TRLYHIBGE meets strict functional safety requirements for applications like turbine overspeed protection and emergency shutdowns. Its fail-safe relay design ensures predictable system behavior during power outages or controller failures .

Flexible Integration: Seamlessly compatible with GE’s Mark VI/VIE controllers and ToolboxST software, the module supports remote firmware updates and parameter adjustments. This scalability allows easy integration into existing or upgraded turbine control systems, aligning with Industry 4.0 initiatives .

Application Areas

Power Generation:

- Gas/Steam Turbines: Controls fuel valves, synchronizes with the electrical grid, and monitors critical parameters like shaft vibration and bearing temperature.

- Combined-Cycle Plants: Manages load sharing between turbines and ensures optimal energy output while adhering to emissions regulations .

Oil & Gas:

- Upstream/Downstream Facilities: Controls compressor anti-surge valves, monitors wellhead pressures, and supports safety interlocks in hazardous areas. Its IP65 rating makes it suitable for outdoor installations .

- Pipeline Systems: Processes flow rate and pressure data for real-time pipeline management, reducing downtime due to leaks or blockages.

Industrial Manufacturing:

- Chemical Processing: Regulates reactor temperatures and distillation unit parameters, ensuring product quality and compliance with safety standards.

- Pulp & Paper Mills: Manages motor control centers (MCCs) and monitors sensor data in high-humidity environments, minimizing equipment degradation .

Water/Wastewater:

- Pump Stations: Controls pump 启停 and monitors water quality sensors, ensuring continuous operation during utility outages.

- Treatment Plants: Processes flow rates and chemical dosing signals for regulatory reporting and operational efficiency .

Related Products

GE GENERAL ELECTRIC DS200TCEBG1AAB PROTECTION

GE FANUC DS200TCEBG1ACE Module

DS200TCEAG1BTF – In Stock & Ready To Ship

General Electric DS200TCEAG1BSF Emergency

DS200SIOBG1AAA – In Stock Now | Fast Global Shipping

Installation and Maintenance

Installation Preparation:

- ESD Precautions: Handle the IS200TRLYHIBGE with anti-static gloves and store it in ESD-protective packaging. Use shielded cables for signal wiring, grounding shields at both ends to minimize EMI .

- Physical Mounting: Secure the module on a DIN rail within a Mark VIe rack, ensuring at least 2.5 cm of clearance for airflow. Connect redundant 24V DC power cables and fieldbus connections to the controller .

- Software Setup: Use ToolboxST to configure relay logic, enable diagnostic logging, and verify communication with the main controller. Perform a functional test before full system commissioning .

Maintenance Recommendations:

- Routine Checks: Inspect LED indicators monthly for power, communication, or fault status. Clean dust from vents and terminals using a dry, lint-free cloth .

- Firmware Updates: Schedule annual firmware updates via ToolboxST to address security patches and enhance compatibility with newer Mark VIe components.

- Component Replacement: Replace relays or surge protection components with GE-certified spares if failures occur. For board-level repairs, contact GE-authorized service centers to ensure compliance with safety standards .

Product Warranty and Support

GE guarantees the IS200TRLYHIBGE against defects for 1 year from purchase. Customers receive:

- Global Technical Support: 24/7 access to GE-certified engineers for remote diagnostics and troubleshooting.

- Comprehensive Documentation: Datasheets, wiring diagrams, and safety manuals available via GE’s online portal.

- Upgrade Path: Transition to the IS200TRLYH2FAA for advanced cybersecurity features or integrate with GE’s Predix IoT platform for predictive analytics .

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com