Description

Many products are not yet available—feel free to contact us for more options.

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Product Overview

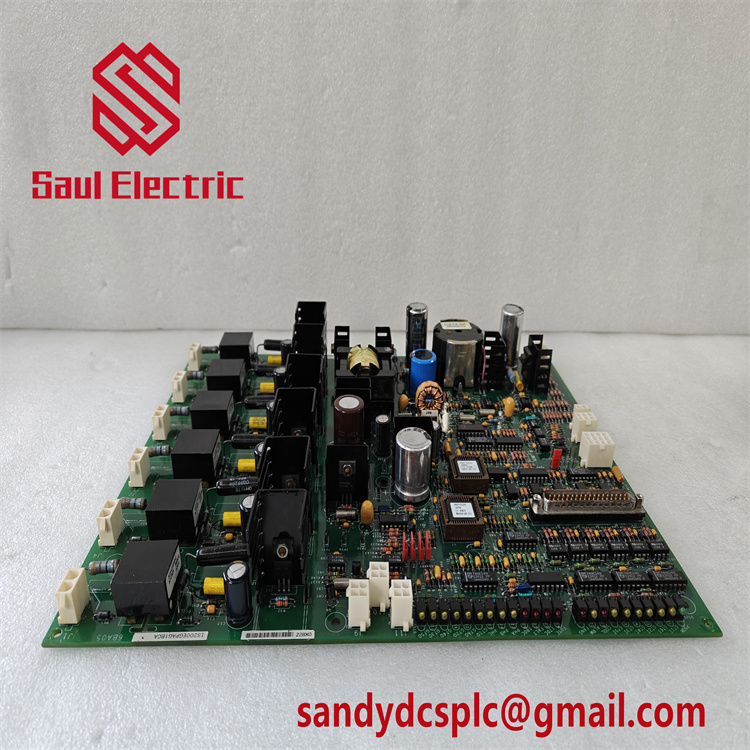

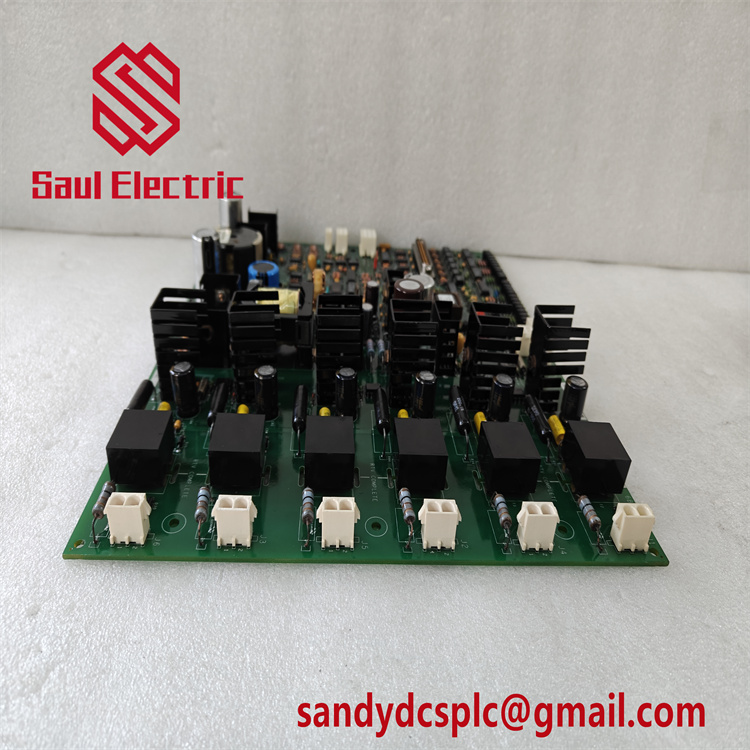

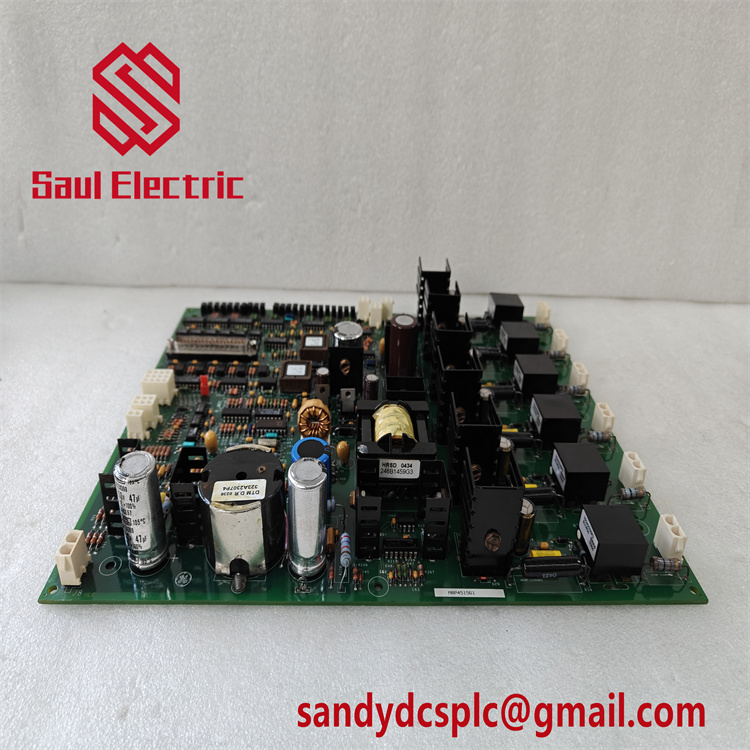

The GE IS200TRLYH3E is a high-performance solid-state relay output terminal board engineered for mission-critical industrial control systems, specifically designed for GE’s Mark VIe platform. Built to meet Class 1 Division 2 certification requirements, this module delivers fail-safe actuation in hazardous environments while providing 12 isolated relay outputs with dual-channel voltage feedback monitoring. Ideal for gas and steam turbine management systems, the GE IS200TRLYH3E ensures precise control of solenoids, valves, and other field devices in explosive atmospheres, combining rugged reliability with advanced diagnostic capabilities.

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS200TRLYH3E |

| Manufacturer | General Electric |

| Product Type | Solid-State Relay Output Terminal Board |

| Output Channels | 12 (isolated, Form A) |

| Input Voltage | 24 V DC / 125 V DC |

| Maximum Load Resistance | 4.5 kΩ (24 V DC) |

| Relay Type | Solid-state (Class 1 Div 2 certified) |

| Diagnostic Features | Dual-channel voltage feedback |

| Redundancy Support | Simplex/TMR |

| Operating Temperature | -30°C to +65°C |

| Board Size | 17.8 cm (W) x 33.02 cm (H) |

| Weight | 0.9 kg (estimated) |

| Mounting Type | DIN rail/panel-mounted |

| Communication Protocol | IONET (Mark VIe standard) |

Hazardous Environment Compliance: The GE IS200TRLYH3E’s Class 1 Division 2 certification allows safe operation in explosive gas or dust environments, making it ideal for offshore platforms, refineries, and chemical plants. Its hermetically sealed relays prevent arc propagation, ensuring compliance with OSHA and IEC 61508 safety integrity level (SIL) requirements.

The GE IS200TRLYH3E is optimized for high-risk industrial applications requiring robust relay control:

- Oil & Gas: Controls blowout preventers (BOPs) and emergency shutdown valves in offshore rigs, ensuring compliance with API 16D standards. Its solid-state design withstands saltwater corrosion and high-vibration environments.

- Power Generation: Manages fuel injection solenoids in gas turbines, providing redundant actuation during load shedding or grid instability. The dual-channel diagnostics help identify degraded relays before they affect turbine performance.

- Chemical Processing: Integrates with reactor safety systems to isolate hazardous processes, meeting OSHA and IEC 61508 safety integrity level (SIL) requirements. Its Form A outputs ensure valves remain open during normal operation and close upon fault detection.

- Mining: Operates heavy machinery in underground environments, leveraging Class 1 Div 2 certification to mitigate explosion risks. The board’s wide temperature tolerance (-30°C to +65°C) ensures reliable operation in extreme climates.

IS200TBAIH1CDD – Analog Input Terminal Board

GE IS200JPDFGIADD Processing Module(XIONGBA) | XIONGBA

IS200TRPGH2BDD – Primary Gas Turbine Trip Output Board

Pre-Installation Preparation: Verify 24 V DC or 125 V DC power supply compatibility and ensure proper grounding. Align the GE IS200TRLYH3E with the Mark VIe I/O rack using DIN rail brackets, securing all connectors (JR1, JS1, JT1) for TMR configurations. Conduct a continuity check to confirm proper wiring before powering up.

GE guarantees the IS200TRLYH3E with a 1-year warranty covering material defects and workmanship. The board undergoes rigorous testing to meet UL 508 and IEC 61131-2 standards, ensuring compliance with global safety protocols. GE’s 24/7 technical support network provides rapid troubleshooting and replacement services, minimizing downtime in critical applications.

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com