Description

Product Overview

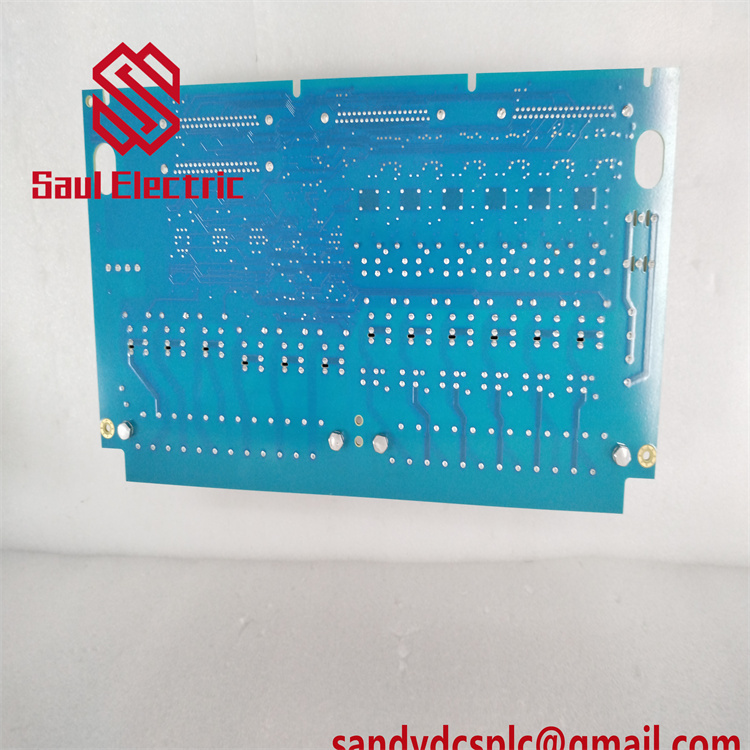

The GE IS200TRLYH1BGG is a high-performance Relay Output Terminal Board engineered for critical industrial control applications, specifically designed for integration with GE’s Mark VI and Mark VIe turbine control systems. As a core component in gas and steam turbine control systems, this module plays a pivotal role in ensuring safe and reliable operation by managing relay outputs, solenoid actuation, and fault detection mechanisms.

Part of GE’s IS200 series, the IS200TRLYH1BGG supports 12 plug-in magnetic relays grouped into three voting systems, ensuring fail-safe operation even in electrically noisy environments. It interfaces with the I/O controller to monitor turbine speed, valve positions, and safety interlocks, triggering rapid shutdowns in abnormal conditions. The module features conformal coating and surge protection (Metal Oxide Varistors, MOVs), making it suitable for harsh industrial settings with extreme temperatures (-30°C to +65°C) and high electromagnetic interference 13.

Key functionalities include signal conditioning, voltage isolation, and real-time diagnostic feedback, enabling seamless integration with GE’s Speedtronic™ turbine control platforms. The IS200TRLYH1BGG supports 24/48/125V DC input voltages and includes hardware filtering to eliminate high-frequency noise, ensuring accurate signal transmission. Its modular design allows for easy installation and maintenance, with plug-and-play compatibility with GE’s PDIO I/O packs for distributed control system (DCS) configurations 26.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200TRLYH1BGG |

| Manufacturer | General Electric (GE) |

| Product Type | Relay Output Terminal Board |

| Relay Configuration | 12 plug-in magnetic relays (3 groups of 4) |

| Output Options | First 6 relays configurable for dry Form-C contacts or solenoid actuation |

| Power Supply | 24/48/125V DC (standard); 115/230V AC (optional) |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions | 17.8cm (width) x 33.02cm (height) [approximate] |

| Weight | 0.5kg [approximate] |

| Certification | UL, cULus, CE, CSA |

| Communication Protocol | Compatible with GE Mark VIe/VIES controller protocols |

| Noise Suppression | 12V RMS AC voltage rejection |

| Surge Protection | Metal Oxide Varistors (MOVs) for transient voltage protection |

| Fault Detection | Loss of relay excitation current, coil current mismatch, communication loss |

Key Features and Advantages

High Reliability in Harsh Environments: The IS200TRLYH1BGG incorporates industrial-grade components and conformal coating to withstand extreme temperatures, voltage fluctuations, and environmental contaminants. Its robust design minimizes downtime and reduces maintenance costs, critical for continuous operations in power plants and oil refineries .

Fail-Safe Relay Control: With 12 Form-C relays configured in a voting system, the module ensures reliable turbine shutdown in emergency scenarios. The first six relays support direct actuation of high-power devices like solenoids and motors, while relays 7–12 provide isolated contacts for specialized applications (e.g., ignition transformers) .

Flexible Signal Handling: The module supports a wide range of input voltages (24/48/125V DC) and includes hardware filtering to adapt to diverse sensor types and ensure signal integrity in electrically noisy environments. Power sources are protected by individual jumper-selectable fuses and MOVs .

Seamless Integration: As part of GE’s Mark VI ecosystem, the IS200TRLYH1BGG leverages GE’s proven architecture for plug-and-play compatibility with PDIO I/O packs and controllers. This integration simplifies system setup and enhances interoperability, making it ideal for retrofitting legacy systems or building new automation infrastructure 8.

Advanced Diagnostics: Built-in diagnostics monitor signal integrity, power status, and relay health, providing real-time feedback to operators. Fault indicators and error codes help identify issues early, preventing costly process interruptions .

Application Areas

The GE IS200TRLYH1BGG excels in mission-critical applications across industries requiring precise relay control:

- Power Generation: Deployed in gas and steam turbine control systems to monitor turbine speed, valve positions, and safety interlocks. Its reliability is essential for maintaining grid stability and optimizing energy production .

- Oil & Gas: Used in upstream and downstream facilities to control pumps, compressors, and emergency shutdown systems. The module’s surge protection ensures safe operation in high-voltage environments .

- Industrial Automation: Integrates with PLCs and DCS systems for machine control, conveyor systems, and quality control in manufacturing. Its modular design supports scalable automation solutions .

- Water Treatment: Manages pump activation, valve switching, and alarm systems in wastewater treatment plants, ensuring compliance with environmental standards .

Related Products

GE IS200TDBTH6AAA PLC Module Via FEDEX/DHL

GE IS200TRPGHIBDD Generator Power Terminal Board

GE IS200STCIHIA Control Input Terminal Board

Installation and Maintenance

Installation Preparation:

Ensure the Mark VIe controller chassis is powered off and properly grounded. Align the IS200TRLYH1BGG with the backplane connectors, pressing firmly until it clicks into place. Use #18 AWG wires for signal connections, following the terminal block labeling (TB1 for relay outputs, TB2 for input contacts). Verify the module’s configuration settings match the input voltage range using GE’s Proficy® software. Connect the J1 power cable to the trip solenoids and the J2 cable to the TSVO terminal board for servo valve clamping in simplex systems .

Ensure the Mark VIe controller chassis is powered off and properly grounded. Align the IS200TRLYH1BGG with the backplane connectors, pressing firmly until it clicks into place. Use #18 AWG wires for signal connections, following the terminal block labeling (TB1 for relay outputs, TB2 for input contacts). Verify the module’s configuration settings match the input voltage range using GE’s Proficy® software. Connect the J1 power cable to the trip solenoids and the J2 cable to the TSVO terminal board for servo valve clamping in simplex systems .

Maintenance Recommendations:

Regularly inspect the IS200TRLYH1BGG for loose connections, physical damage, or signs of corrosion. Clean the module with a dry, lint-free cloth to remove dust and debris. Monitor diagnostic LEDs for errors, such as signal loss or relay failure. Replace worn-out relays or damaged components promptly, ensuring compatibility with GE’s recommended spares. GE’s technical support team provides guidance on firmware updates and troubleshooting. For offline testing, use GE’s software to simulate relay operation and verify response times .

Regularly inspect the IS200TRLYH1BGG for loose connections, physical damage, or signs of corrosion. Clean the module with a dry, lint-free cloth to remove dust and debris. Monitor diagnostic LEDs for errors, such as signal loss or relay failure. Replace worn-out relays or damaged components promptly, ensuring compatibility with GE’s recommended spares. GE’s technical support team provides guidance on firmware updates and troubleshooting. For offline testing, use GE’s software to simulate relay operation and verify response times .

Product Warranty and Support

GE guarantees the IS200TRLYH1BGG against defects in materials and workmanship for 1 year from the date of purchase. This warranty covers replacement or repair of the module if deemed faulty under normal use. For assistance, customers can access GE’s global network of certified technicians, who offer 24/7 technical support, remote diagnostics, and on-site service. The company also provides comprehensive documentation, including datasheets, installation guides, and application notes, to aid in system design and maintenance .

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com