Description

Many products are not yet available—feel free to contact us for more options.

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Product Overview

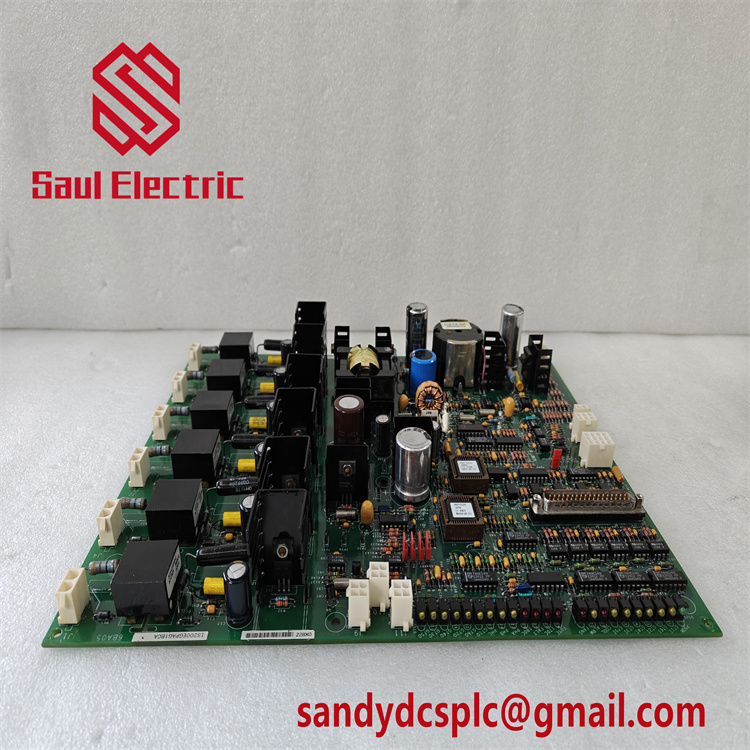

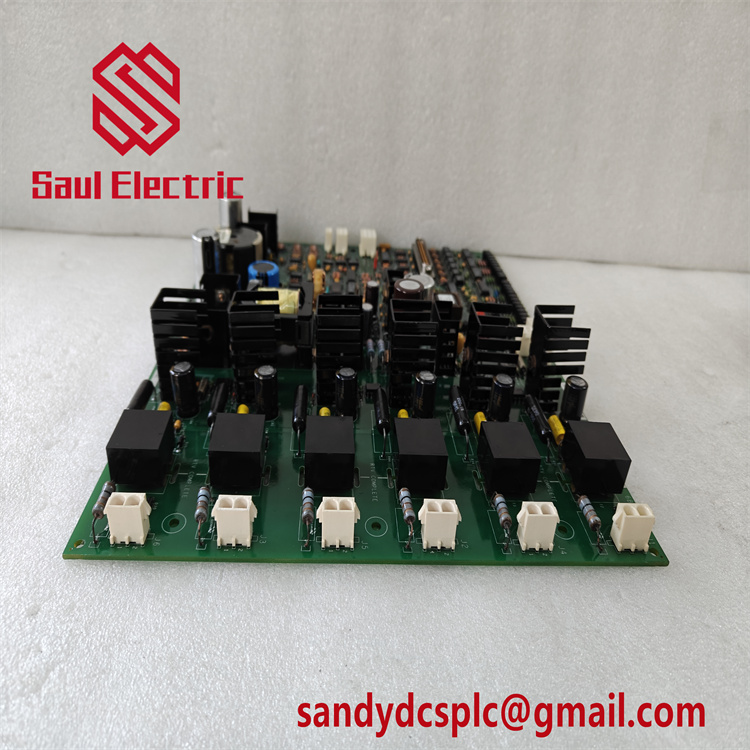

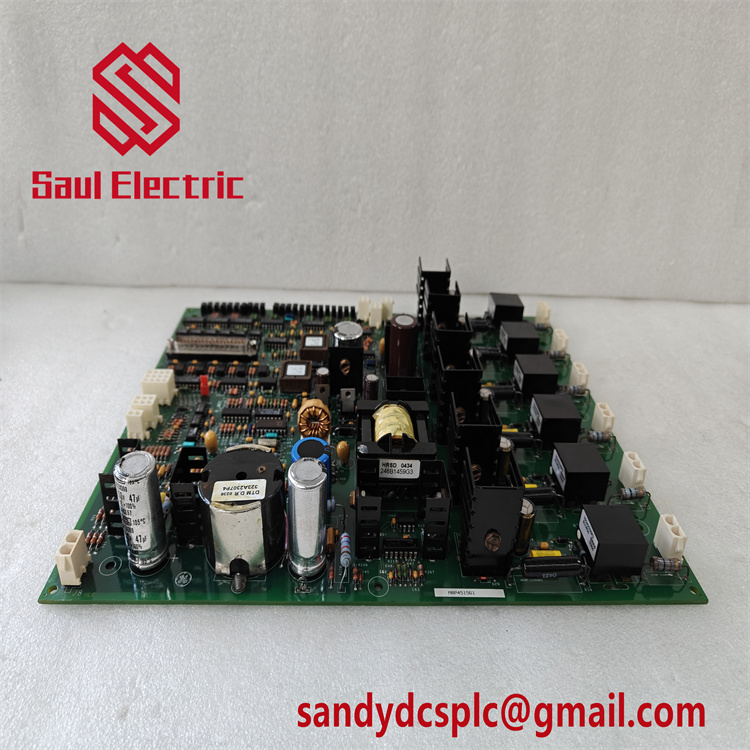

The GE IS200TREAS1A is a high-performance emergency trip terminal board engineered for critical turbine control systems. As part of GE’s renowned Mark VIe series, this module is designed to deliver reliable overspeed protection and emergency shutdown capabilities for aeroderivative gas turbines. With its rugged construction and advanced signal processing, the GE IS200TREAS1A ensures precise monitoring of turbine speed and rapid actuation of trip solenoids, safeguarding equipment integrity and operational safety.

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IS200TREAS1A |

| Manufacturer | General Electric |

| Product Type | Emergency Trip Terminal Board |

| Input Channels | 7 dry contact inputs |

| Output Solenoids | 3 (125 V DC rated) |

| Solenoid Response Time | 0.1 sec (L/R time constant) |

| Power Supply Voltage | 24 V DC |

| Operating Temperature | -30°C to +65°C |

| Board Size | 33.0 cm (H) x 17.8 cm (W) |

| Weight | 1.5 kg (estimated) |

| Installation Type | Rack-mounted |

| Communication Protocol | IONET (Mark VIe standard) |

Reliable Overspeed Protection: The GE IS200TREAS1A integrates seven independent trip interlock inputs to detect deviations in turbine speed, triggering immediate shutdown via three redundant solenoids. This design ensures fail-safe operation even in harsh industrial environments.

The GE IS200TREAS1A excels in mission-critical turbine control scenarios across multiple industries:

- Power Generation: Used in gas turbine generators to prevent overspeed events during load changes or grid disturbances, ensuring stable electricity production.

- Oil & Gas: Integral to compressor turbine protection systems in offshore platforms and refineries, where equipment reliability is non-negotiable.

- Industrial Manufacturing: Deployed in steam turbines for process heating and mechanical drive applications, providing emergency shutdown capabilities to protect machinery and personnel.

- Renewable Energy: Supports wind turbine gearbox control systems, minimizing downtime during grid synchronization or fault conditions.

IS200TBAIH1CDD – Analog Input Terminal Board

GE IS200JPDFGIADD Processing Module(XIONGBA) | XIONGBA

IS200TRPGH2BDD – Primary Gas Turbine Trip Output Board

Installation Preparation: Prior to installing the GE IS200TREAS1A, verify the system’s power supply compatibility (24 V DC) and ensure proper grounding. Clean the mounting rack and inspect connectors for debris. Follow GE’s Mark VIe installation guidelines to align the board with the I/O controller and solenoid wiring.

GE stands behind the IS200TREAS1A with a comprehensive 1-year warranty covering manufacturing defects. The board undergoes rigorous testing to meet ISO 9001 quality standards, ensuring consistent performance across applications. For technical support, certified engineers are available to assist with troubleshooting, configuration, and system integration. A global network of authorized service centers guarantees prompt repairs and replacements, minimizing downtime.

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com