Description

Many products are not yet available—feel free to contact us for more options.

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Product Overview

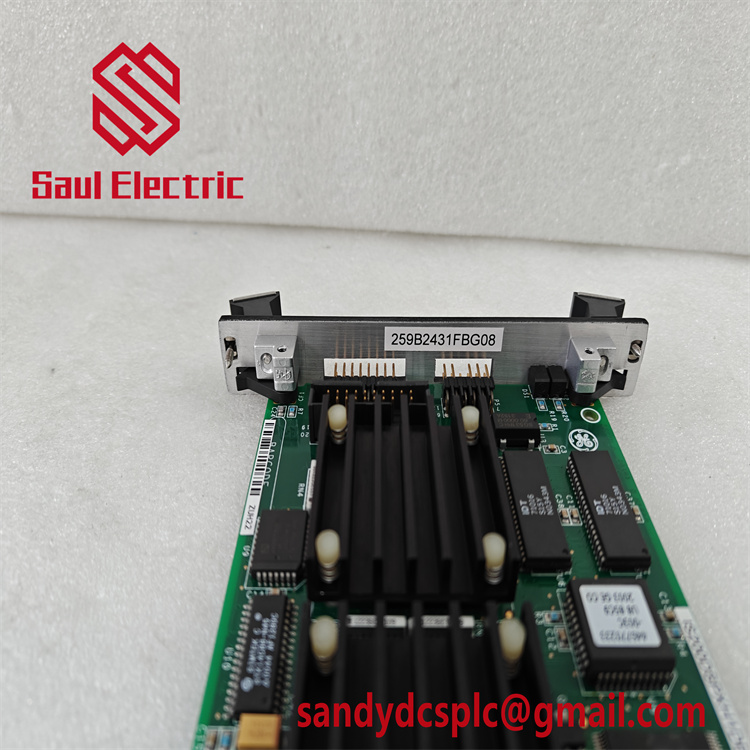

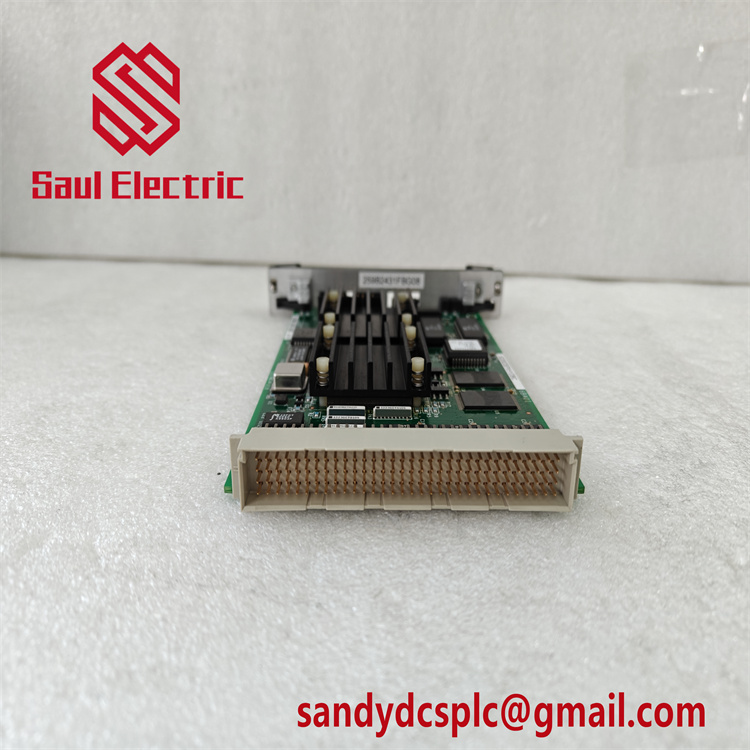

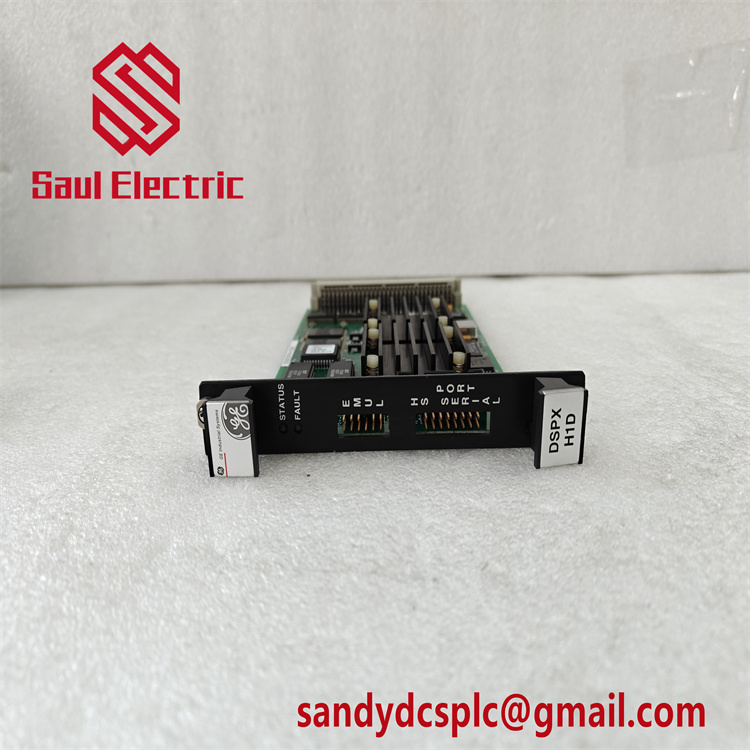

The GE IS200SPIDG1A is a high-performance control motherboard module designed for industrial automation systems, particularly within GE’s Mark VI and Mark VIe distributed control platforms. This module serves as a critical communication and processing hub, integrating multiple interfaces to coordinate data exchange between sensors, actuators, and central controllers. Engineered for reliability in harsh environments, the GE IS200SPIDG1A supports real-time monitoring and control of industrial processes, such as turbine management and manufacturing automation. Its compact design and robust architecture ensure seamless compatibility with existing GE Speedtronic systems, providing enhanced data integrity and operational efficiency for power generation, oil and gas, and heavy industrial applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200SPIDG1A |

| Manufacturer | GE (General Electric) |

| Product Type | Control Motherboard Module |

| Dimensions | 118mm × 19mm × 130mm (4.65″ × 0.75″ × 5.12″) |

| Weight | 0.5kg (1.1 lbs) |

| Power Supply | 24V DC ±10% |

| Operating Temperature | -40°C to +85°C |

| Communication Protocols | Profibus DP, Modbus TCP/IP |

| I/O Interfaces | Digital/Analog Inputs/Outputs, RS-485 |

| Isolation Voltage | 2500V AC (channel-to-ground) |

| Protection Rating | IP20 (dust/light moisture resistance) |

| Certifications | CE, RoHS, UL |

Key Features and Advantages

Multi-Protocol Integration: The GE IS200SPIDG1A natively supports Profibus DP and Modbus TCP/IP, enabling interoperability with diverse industrial devices without additional gateways. This reduces system complexity and latency in critical operations like turbine control.

Ruggedized Design: With an operational range of -40°C to 85°C and conformal-coated PCBs, the module withstands extreme temperatures, humidity, and corrosive atmospheres in offshore rigs or steel plants. Its IP20 rating ensures resilience against particulate ingress.

Diagnostic Capabilities: Embedded self-diagnostics continuously monitor module health, detecting faults such as overvoltage or communication errors. LED indicators provide instant status alerts, minimizing troubleshooting time and preempting system failures.

Application Areas

Power Generation: In gas/steam turbines, the GE IS200SPIDG1A processes sensor data (e.g., vibration, temperature) for predictive maintenance, optimizing turbine efficiency and preventing unplanned downtime.

Oil & Gas: Deployed in refineries and compressor stations, it coordinates safety-critical functions like emergency shutdown systems (ESD) and pipeline pressure control, ensuring compliance with SIL-2/3 standards.

Manufacturing Automation: Acts as a backbone for PLC/DCS networks in automotive or semiconductor production lines, synchronizing robotic arms and conveyor systems via high-speed I/O interfaces.

Related Products

IS200TBAIH1CDD – Analog Input Terminal Board

GE IS200JPDFGIADD Processing Module(XIONGBA) | XIONGBA

IS200TRPGH2BDD – Primary Gas Turbine Trip Output Board

Installation and Maintenance

Installation Preparation: Mount the GE IS200SPIDG1A on DIN rails (EN 60715-compliant) using M4 screws. Ensure 50mm clearance from heat sources and route communication cables (e.g., shielded twisted pairs) away from power lines to prevent EMI. Verify grounding resistance <1Ω before energizing.

Maintenance Recommendations: Clean air vents quarterly with dry compressed air (<30 PSI). Calibrate I/O channels annually using a precision signal generator. Update firmware via GE’s Proficy software to patch vulnerabilities and enhance protocol support. Replace backup batteries every 2 years to retain configuration data.

Product Assurance

The GE IS200SPIDG1A includes a 1-year global warranty covering defects in materials and workmanship. GE provides lifetime technical support through 24/7 hotlines and on-site service within 48 hours for critical failures. All modules undergo MIL-STD-810G shock/vibration testing and ISO 9001:2015-certified manufacturing, with field failure rates below 0.25%.

HS:7326909000- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com