Description

Product Overview

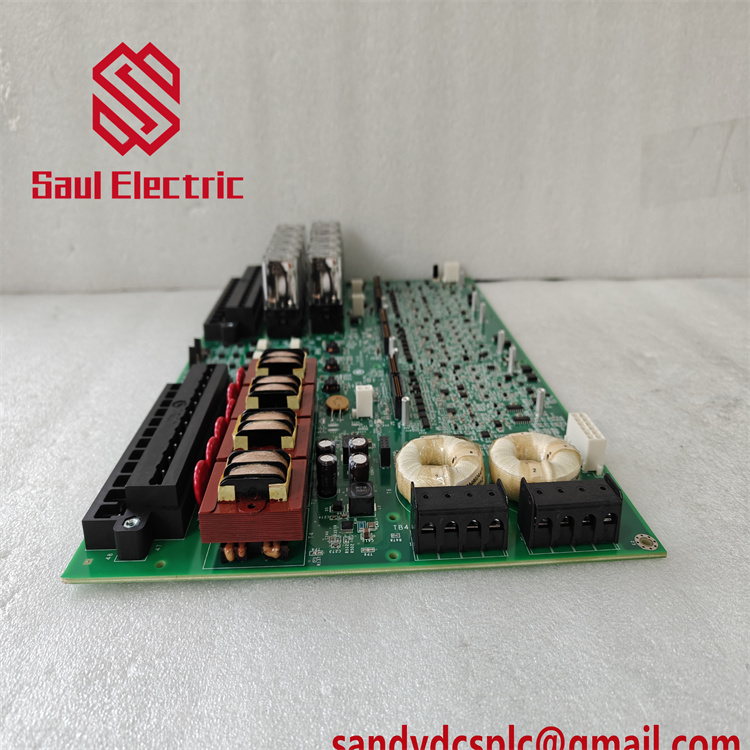

The GE IS200SCLTH1A is a high-performance Signal Conditioning and Logic Terminal Board designed as a critical component in GE’s Mark VI and Mark VIe turbine control systems, specifically engineered for gas, steam, and hydro turbine applications. As part of GE’s renowned IS200 series, this module serves as a bridge between field sensors, actuators, and the main controller, processing analog and digital signals with precision to ensure real-time turbine operation and safety.

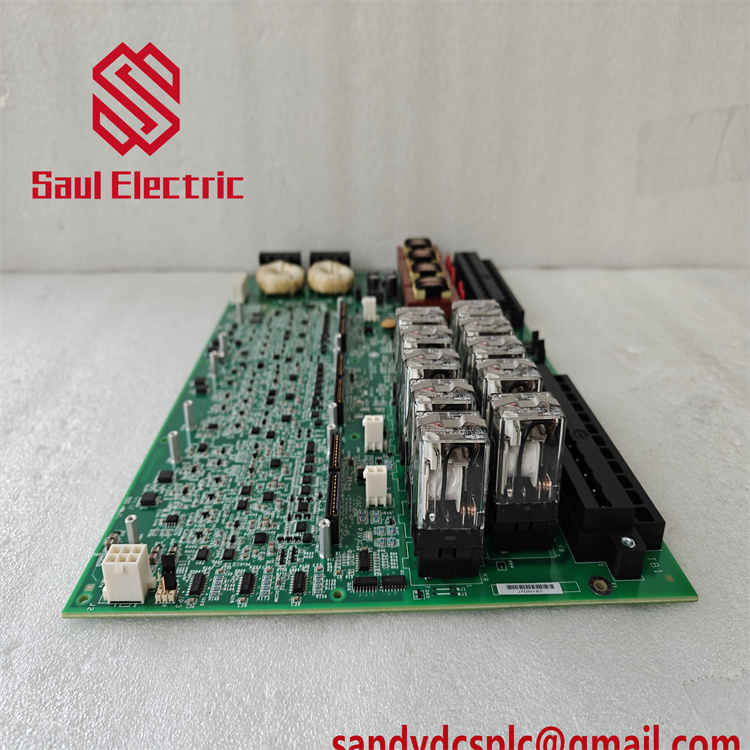

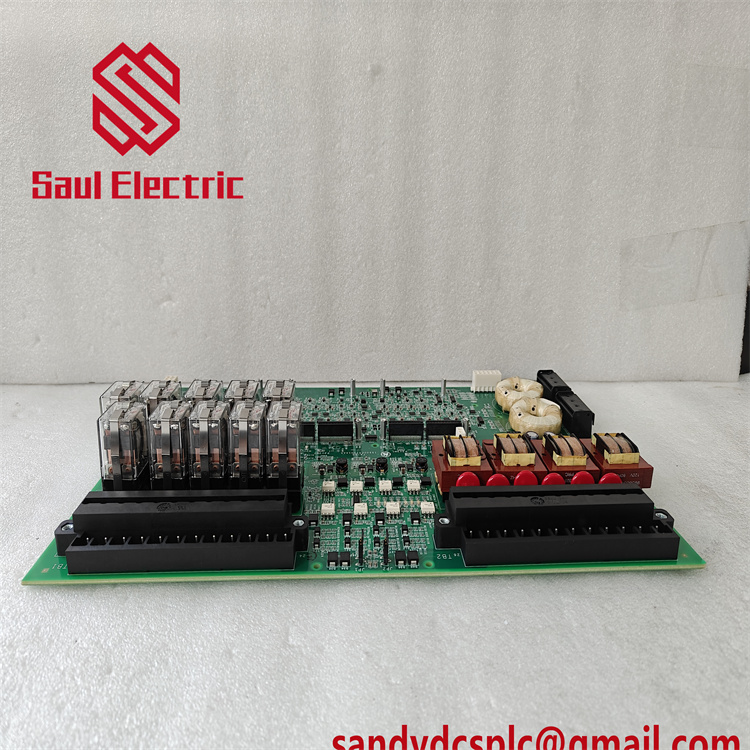

Equipped with advanced signal conditioning circuitry, the IS200SCLTH1A converts raw sensor data (e.g., temperature, pressure, vibration) into usable signals for the controller, while filtering out electromagnetic interference (EMI) to maintain signal integrity. It features 16 isolated input channels and 8 relay outputs, supporting a wide range of signal types (4-20mA, 0-10V DC, and dry contacts), making it highly versatile for diverse industrial environments. The module’s rugged design includes conformal coating and surge protection (MOVs), enabling reliable operation in harsh conditions (-30°C to +65°C) common in power plants and oil refineries.

Seamlessly integrating with GE’s Speedtronic™ platform, the IS200SCLTH1A communicates via GE’s proprietary fieldbus protocol, ensuring compatibility with Mark VIe controllers and ToolboxST configuration software. Its compact form factor and DIN rail mounting simplify installation in control cabinets, while built-in diagnostics (LED indicators and fault logging) provide real-time system health insights, reducing troubleshooting time.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200SCLTH1A |

| Manufacturer | General Electric (GE) |

| Product Type | Signal Conditioning and Logic Terminal Board |

| Input Channels | 16 isolated analog/digital inputs (4-20mA, 0-10V DC, dry contacts) |

| Output Channels | 8 Form-C relay outputs (250V AC/30V DC, 5A) |

| Power Supply | 24V DC ±10% (redundant inputs), 10W maximum consumption |

| Communication Protocol | Compatible with GE Mark VI/VIE fieldbus and Modbus RTU (via adapter) |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions | 22.86 cm (length) × 15.24 cm (width) × 7.62 cm (depth) |

| Weight | 0.6 kg |

| Certifications | UL, cULus, CE, IEC 61508 (SIL 2 compliant) |

| Mounting | DIN rail or panel mount (with optional brackets) |

| EMI/RFI Protection | Integrated filters and shielding for industrial EMI environments |

Key Features and Advantages

Precise Signal Conditioning: The IS200SCLTH1A incorporates high-resolution ADCs and low-pass filters to clean and amplify sensor signals, ensuring accurate data transmission to the controller. This precision is critical for turbine speed regulation and combustion control, where even minor signal errors could lead to inefficiencies or safety risks.

Rugged Industrial Design: Built to withstand extreme temperatures, vibration, and moisture, the module’s conformal coating and surge protection (MOVs) safeguard against environmental stressors in power generation and oil & gas facilities. Its wide operating temperature range (-30°C to +65°C) ensures reliability in both arctic and desert conditions.

Flexible Integration: With support for multiple signal types and compatibility with Mark VI/VIE systems, the IS200SCLTH1A adapts to diverse turbine configurations, from simple single-shaft to complex multi-stage turbines. It integrates seamlessly with GE’s ToolboxST software for easy configuration, calibration, and firmware updates.

Enhanced Diagnostics: LED indicators for power, communication, and channel faults provide at-a-glance system status, while detailed fault logs (accessible via ToolboxST) enable root-cause analysis. This reduces mean time to repair (MTTR) and minimizes unplanned downtime.

Safety Compliance: Certified to IEC 61508 SIL 2, the IS200SCLTH1A meets strict functional safety standards, making it suitable for safety-critical loops such as overspeed protection and emergency shutdown systems (ESD), where failure could have catastrophic consequences.

Application Areas

The GE IS200SCLTH1A is indispensable in industries requiring precise turbine control and signal processing:

- Power Generation: Deployed in gas, steam, and hydro turbine control systems to monitor shaft vibration, bearing temperature, and steam pressure, ensuring optimal efficiency and grid stability. It plays a key role in load sharing between turbines and synchronizing with the electrical grid.

- Oil & Gas: Used in upstream and downstream facilities to control compressor turbines, monitoring fuel gas pressure and anti-surge valve positions. Its EMI filtering is critical for reliable operation in electrically noisy environments near pumps and motors.

- Industrial Turbines: Integrates with turbine-driven pumps and generators in chemical plants and manufacturing facilities, regulating process parameters to maintain product quality and safety.

- Renewable Energy: Supports hydroelectric turbine systems, processing water flow and turbine speed data to maximize energy output while adhering to environmental regulations.

Related Products

GE GENERAL ELECTRIC DS200TCEBG1AAB PROTECTION

GE FANUC DS200TCEBG1ACE Module

DS200TCEAG1BTF – In Stock & Ready To Ship

General Electric DS200TCEAG1BSF Emergency

DS200SIOBG1AAA – In Stock Now | Fast Global Shipping

Installation and Maintenance

Installation preparation: Ensure the Mark VIe control cabinet is properly grounded and ventilated. Mount the IS200SCLTH1A on a DIN rail using the provided brackets, securing it to prevent vibration. Connect field wiring to the terminal blocks (TB1 for inputs, TB2 for outputs) using #16-22 AWG shielded cables, ensuring proper grounding of shields to minimize EMI. Verify redundant 24V DC power connections and use ToolboxST to configure input ranges and relay logic before powering on.

Maintenance recommendations: Inspect the IS200SCLTH1A quarterly for loose connections or corrosion, cleaning terminals with a dry cloth. Monitor LED indicators for fault codes (e.g., red LED for power loss) and use ToolboxST to review diagnostic logs. Replace relays or surge protection components with GE-certified spares if failures occur. Schedule annual firmware updates via ToolboxST to ensure compatibility with newer Mark VIe system components.

Product Warranty

GE guarantees the IS200SCLTH1A against defects in materials and workmanship for 1 year from the date of purchase. This coverage includes repair or replacement of faulty modules under normal operating conditions. Customers benefit from GE’s global technical support network, offering 24/7 remote diagnostics, on-site service, and access to comprehensive documentation (datasheets, wiring guides) to ensure seamless integration and operation. GE also provides training programs to help technicians maximize the performance of the IS200SCLTH1A in turbine control systems.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com