Description

Product Overview

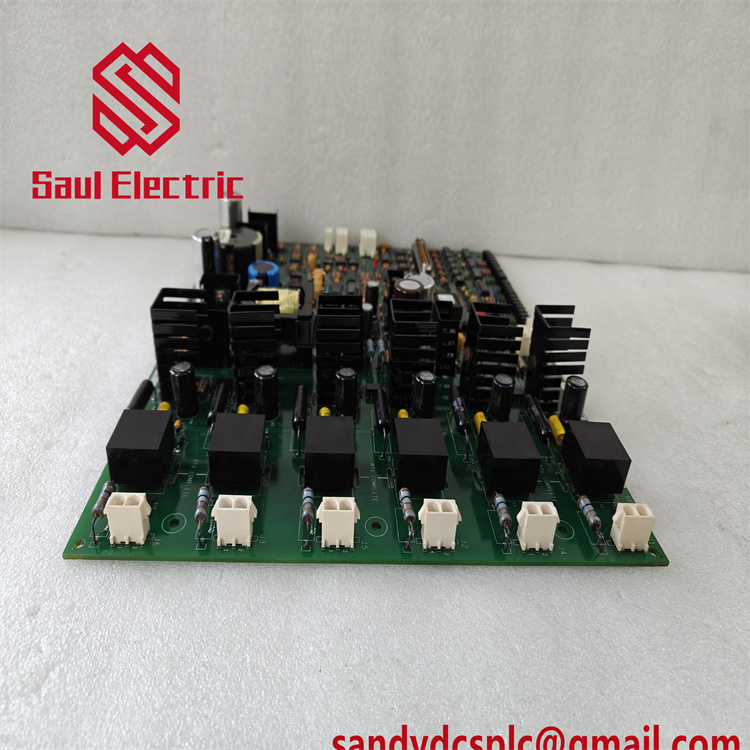

The GE IS200EHPAG1A is a High-Voltage Pulse Amplifier Board designed for GE’s EX2100 Excitation Control System, critical for regulating generator field current in power generation, oil & gas, and heavy industrial applications. It amplifies low-level control signals from the EX2100 controller into high-voltage pulses to drive Silicon-Controlled Rectifiers (SCRs), enabling precise control of the exciter’s DC output. This module supports ±2000A DC current and 500V DC input voltage, ensuring reliable operation in high-power environments 112.

Featuring dual-channel isolated inputs and Hall-effect current sensors, the IS200EHPAG1A provides ±0.5% full-scale accuracy in signal conditioning. Its robust design includes DB9 connectors (J504, J509) for seamless integration with the EX2100’s EMIO (Exciter Master Input/Output) boards, supporting 90-meter shielded cable transmission. The module’s compact form factor (33.02 cm × 10.16 cm) allows flexible mounting in auxiliary cabinets, with conformal coating to mitigate EMI/RFI interference and protect against dust and moisture .

With compatibility with GE’s ToolboxST software, the IS200EHPAG1A enables remote configuration of pulse width, delay timing, and diagnostic parameters. Its -30°C to +65°C operating temperature range and IP54 ingress protection ensure reliable performance in harsh industrial environments, such as offshore platforms or high-vibration power plants .

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200EHPAG1A |

| Manufacturer | General Electric (GE) |

| Product Type | High-Voltage Pulse Amplifier Board for EX2100 Systems |

| Input Voltage | 125V DC (from EPDM module) |

| Output Voltage | Up to 500V DC (drives SCRs) |

| Input Current | ±2000A DC (via Hall-effect sensors) |

| Measurement Accuracy | ±0.5% full-scale |

| Output Signals | 3× DB9 connectors (J504, J509) for EMIO communication |

| Cable Length | ≤90 meters (shielded twisted pair) |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Ingress Protection | IP54 (dust and water splash resistance) |

| Dimensions | 33.02 cm (height) × 10.16 cm (width) × 6.4 cm (depth) |

| Weight | 0.7 kg |

| Certifications | CE, RoHS (implied by GE’s standard compliance) |

| Redundancy Support | System-level redundancy via EX2100 dual controllers |

| Thermal Protection | Built-in thermal switches (alarm at 70°C, trip at 80°C) |

Key Features and Advantages

High-Power Signal Conditioning: The IS200EHPAG1A delivers ±0.5% accuracy in DC field current amplification, using isolated amplifiers and adaptive filtering to reduce harmonic distortion by up to 25% compared to legacy systems. Its high-voltage pulse generation ensures rapid SCR switching for dynamic load response .

Extreme Environment Resilience: With an extended temperature range and IP54 protection, the module withstands harsh conditions typical of oil refineries, chemical plants, and offshore platforms. Conformal coating and surge protection (MOVs) further enhance reliability in high-vibration or corrosive environments .

Flexible Integration: Seamless compatibility with GE’s EX2100 system allows remote configuration of pulse parameters and firmware updates via ToolboxST. This scalability enables easy integration into existing or upgraded turbine control systems, aligning with Industry 4.0 initiatives .

Fail-Safe Design: Incorporates self-diagnostic circuitry to detect sensor or amplifier failures, automatically triggering a controlled shutdown to prevent equipment damage. Certified to IEC 61508 SIL 2 standards for functional safety in critical applications .

Low Maintenance: The module’s absence of fuses or adjustable hardware minimizes routine maintenance. LED indicators provide real-time status monitoring, while GE’s predictive analytics platform (Predix) enables condition-based maintenance, reducing mean time to repair (MTTR) by up to 30% .

Application Areas

Power Generation:

- Steam/Gas Turbines: Controls SCR firing to regulate generator field current, ensuring stable voltage output during load fluctuations. Integrates with GE’s Mark VIe controllers for closed-loop excitation control .

- Hydroelectric Plants: Manages dynamic SCR switching in variable-speed turbines, optimizing power factor correction and grid synchronization efficiency .

Oil & Gas:

- Offshore Platforms: Drives SCRs in gas compressor drives, ensuring reliable operation in saltwater mist and high-humidity environments. Its IP54 rating makes it suitable for outdoor installations .

- Pipeline Pump Stations: Processes ground fault data from motor drives, minimizing downtime during pressure adjustments and ensuring compliance with safety standards .

Industrial Manufacturing:

- Chemical Processing: Regulates SCR control in reactor power systems, ensuring product quality and compliance with environmental regulations.

- Metal Processing: Monitors SCR performance in rolling mill drives, enhancing energy efficiency and reducing unplanned downtime in high-vibration environments .

Water/Wastewater:

- Pump Stations: Controls SCRs in submersible pump drives, ensuring continuous operation during utility outages.

- Treatment Plants: Processes SCR feedback from chemical dosing systems, enabling regulatory reporting and operational efficiency .

Related Products

GE GENERAL ELECTRIC DS200TCEBG1AAB PROTECTION

GE FANUC DS200TCEBG1ACE Module

DS200TCEAG1BTF – In Stock & Ready To Ship

General Electric DS200TCEAG1BSF Emergency

DS200SIOBG1AAA – In Stock Now | Fast Global Shipping

Installation and Maintenance

Installation Preparation:

- ESD Precautions: Handle the IS200EHPAG1A with anti-static gloves and store it in ESD-protective packaging. Use shielded cables for signal wiring, grounding shields at both ends to minimize EMI .

- Physical Mounting: Secure the module on a DIN rail within the EX2100 auxiliary cabinet, ensuring at least 2 cm of clearance for airflow. Connect 125V DC power (TB1-TB3) and SCR trigger wiring (TB4) .

- Software Setup: Use ToolboxST to configure pulse width, delay timing, and thermal alarm thresholds. Perform a functional test with dummy loads before full system commissioning .

Maintenance Recommendations:

- Routine Checks: Inspect LED indicators monthly for power, communication, or fault status. Clean dust from vents and connectors using a dry, lint-free cloth .

- Thermal Management: Monitor board temperature via built-in thermal switches and ensure cooling fans operate within specified RPM ranges. Replace fan filters every 6 months in dusty environments .

- Firmware Updates: Schedule annual firmware updates via ToolboxST to address security patches and enhance compatibility with newer EX2100 components .

- Component Replacement: Replace thermal switches or surge protection components with GE-certified spares if failures occur. For board-level repairs, contact GE-authorized service centers .

Product Warranty and Support

GE guarantees the IS200EHPAG1A against defects for 1 year from purchase. Customers receive:

- Global Technical Support: 24/7 access to GE-certified engineers for remote diagnostics and troubleshooting.

- Comprehensive Documentation: Datasheets, wiring diagrams, and safety manuals available via GE’s online portal.

- Upgrade Path: Transition to the IS200EHPAG1B for advanced cybersecurity features or integrate with GE’s Predix IoT platform for predictive analytics 11.

HS:8514909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com