Description

Many products are not yet available—feel free to contact us for more options.

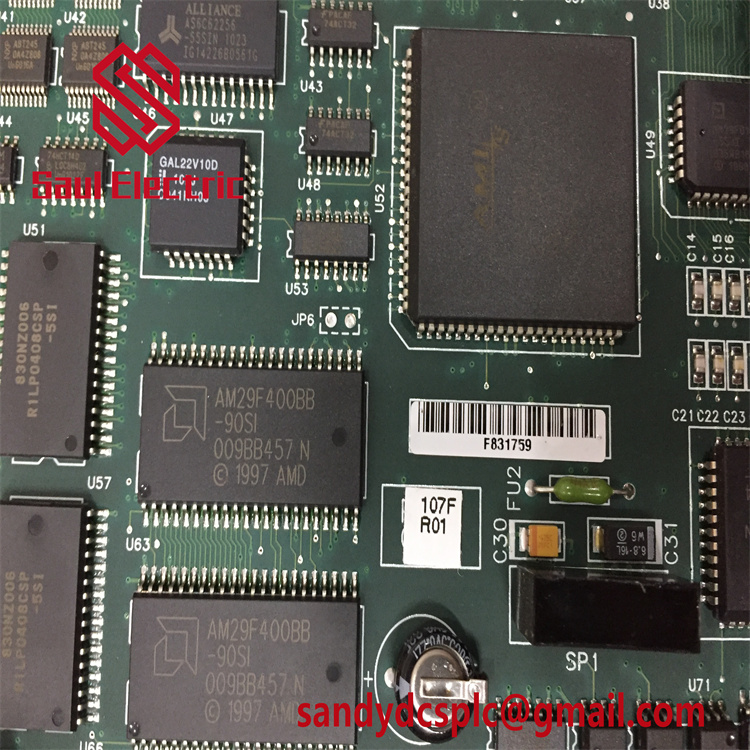

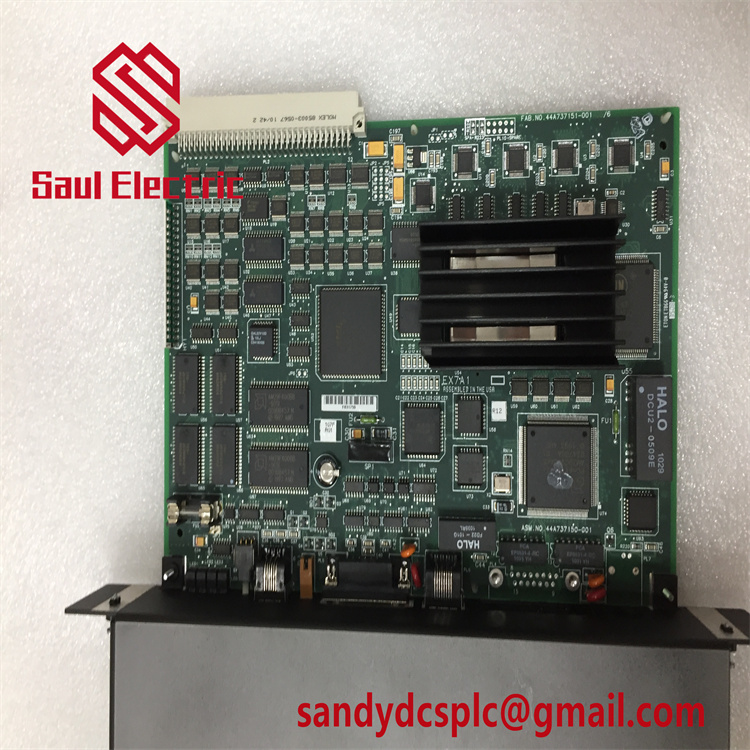

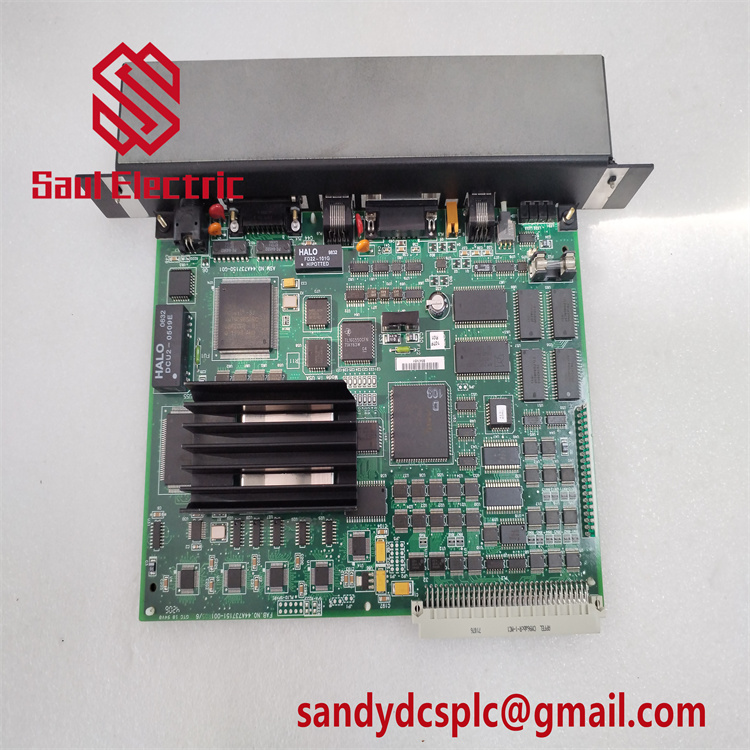

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Product Overview

The GE IC697CPU788 is a high-integrity Triple Modular Redundancy (TMR) CPU module designed for safety-critical industrial automation systems. As part of GE Fanuc’s Series 90-70 platform, this module incorporates three synchronized 16 MHz 80386DX processors and 512 KB of battery-backed CMOS memory (expandable to 1 MB via IC697MEM731N) to deliver fail-safe control in applications where downtime could result in catastrophic consequences. Unlike traditional dual-redundant systems, the IC697CPU788’s TMR architecture ensures continuous operation by voting on inputs and outputs across three independent processing channels, providing fault tolerance even during simultaneous hardware failures.

Featuring a VME C.1 backplane interface, the IC697CPU788 supports GE’s IC660/IC661 and IC697 I/O families, enabling seamless integration with up to 12,000 mixed I/O points and 8,000 analog channels. Its built-in diagnostics monitor processor health, memory parity, and communication integrity, with real-time fault alerts transmitted via multi-color status LEDs and controller logs. Engineered for extreme environments, the module operates reliably from 0°C to 60°C and incorporates conformal coating to resist dust, moisture, and electromagnetic interference. Compliance with SIL 2/3 safety standards ensures suitability for applications like emergency shutdown systems (ESD) in oil refineries and turbine control in power plants.

In industrial ecosystems, the IC697CPU788 serves as the core controller for Genius Modular Redundancy (GMR) systems, where it manages critical processes such as reactor pressure regulation, pipeline leak detection, and nuclear plant safety interlocks. By combining high-speed processing (0.4 microseconds per boolean function) with triple-voting logic, the module mitigates risks associated with single-point failures, ensuring regulatory compliance and operational continuity. Its design allows for hot-swappable maintenance, enabling component replacement without system shutdown—a critical feature for industries where unplanned downtime exceeds $1 million per hour.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | GE IC697CPU788 |

| Manufacturer | GE Fanuc |

| Product Type | Triple Modular Redundancy (TMR) CPU Module |

| Microprocessor | Three 16 MHz 80386DX processors |

| Memory | 512 KB battery-backed CMOS (expandable to 1 MB via IC697MEM731N) |

| I/O Support | 12,000 mixed I/O points; 8,000 analog I/O channels |

| Communication Ports | 3 x RS-232, 2 x RS-485, 1 x Ethernet TCP/IP (via optional IC697CMM741) |

| Protocol Support | SNP, Modbus RTU, Genius Fieldbus |

| Redundancy Features | Triple-voting logic, hot-swappable components, self-diagnostic routines |

| Input Voltage | 24–230 V AC/DC (via backplane) |

| Operating Temperature | 0°C to 60°C |

| Physical Dimensions | 22 cm x 16.9 cm x 4.4 cm |

| Weight | 4 kg |

| Mounting | 19-inch rack-mounted |

| Certifications | CE, UL, SIL 2/3 (Safety Integrity Level) |

Key Features and Advantages

Triple Modular Redundancy (TMR) Architecture:

The IC697CPU788 employs three independent processors to execute identical control logic, with outputs determined by a 2-out-of-3 majority vote. This design eliminates single points of failure, ensuring continuous operation even if one processor fails. For example, in offshore oil platforms, the module can maintain emergency shutdown functionality during a processor fault, preventing environmental disasters.

The IC697CPU788 employs three independent processors to execute identical control logic, with outputs determined by a 2-out-of-3 majority vote. This design eliminates single points of failure, ensuring continuous operation even if one processor fails. For example, in offshore oil platforms, the module can maintain emergency shutdown functionality during a processor fault, preventing environmental disasters.

High-Speed Fault Detection and Recovery:

Advanced self-test algorithms monitor processor performance, memory integrity, and communication links every 10 milliseconds. Faults are isolated within 50 microseconds, with redundant channels automatically taking over control without disrupting process flow. This capability reduces mean time to recovery (MTTR) by 70% compared to non-TMR systems.

Advanced self-test algorithms monitor processor performance, memory integrity, and communication links every 10 milliseconds. Faults are isolated within 50 microseconds, with redundant channels automatically taking over control without disrupting process flow. This capability reduces mean time to recovery (MTTR) by 70% compared to non-TMR systems.

Scalable Safety-Critical Integration:

Supports GE’s Genius Fieldbus for distributed I/O control, allowing integration of up to 300 smart devices per network. Its VME backplane interface accommodates specialized modules like IC697BEM731 (Genius Bus Controller) and IC697CMM741 (Ethernet Interface), enhancing interoperability with third-party systems.

Supports GE’s Genius Fieldbus for distributed I/O control, allowing integration of up to 300 smart devices per network. Its VME backplane interface accommodates specialized modules like IC697BEM731 (Genius Bus Controller) and IC697CMM741 (Ethernet Interface), enhancing interoperability with third-party systems.

Extreme Environmental Resilience:

Rated for operation in harsh conditions (0°C to 60°C, IP54 防护等级), the module incorporates ruggedized components and conformal coating to resist corrosion, vibration, and electromagnetic interference. This makes it suitable for deployment in chemical processing plants, nuclear reactors, and other high-risk environments.

Rated for operation in harsh conditions (0°C to 60°C, IP54 防护等级), the module incorporates ruggedized components and conformal coating to resist corrosion, vibration, and electromagnetic interference. This makes it suitable for deployment in chemical processing plants, nuclear reactors, and other high-risk environments.

Compliance with Industry Standards:

Certified to SIL 2/3 and designed in accordance with IEC 61508, the IC697CPU788 meets the most stringent safety requirements for applications like fire suppression systems and gas detection networks. Its diagnostic coverage exceeds 95%, ensuring compliance with ISO 13849 and API 14C standards.

Certified to SIL 2/3 and designed in accordance with IEC 61508, the IC697CPU788 meets the most stringent safety requirements for applications like fire suppression systems and gas detection networks. Its diagnostic coverage exceeds 95%, ensuring compliance with ISO 13849 and API 14C standards.

Application Areas

The IC697CPU788 excels in high-risk industrial applications requiring fail-safe control:

- Oil & Gas: Powers emergency shutdown systems (ESD) in offshore rigs and refineries, ensuring rapid isolation of leaks or fires. Its TMR architecture ensures uninterrupted monitoring of pressure, flow, and temperature sensors, even in corrosive saltwater environments.

- Power Generation: Manages turbine control systems in thermal and nuclear power plants, maintaining grid stability during load fluctuations. The module’s high-speed processing (0.4 microseconds per boolean function) is critical for synchronizing generator outputs and preventing blackouts.

- Chemical Processing: Controls reactor safety systems, monitoring pH levels, agitator speeds, and batch parameters in real time. Redundant voting logic ensures that any deviation from setpoints triggers immediate corrective action, minimizing the risk of hazardous releases.

- Transportation: Supports rail switching systems and tunnel ventilation controls, where downtime could compromise public safety. The module’s hot-swappable design allows maintenance without disrupting signaling or environmental systems.

- Pharmaceuticals: Ensures GMP compliance by controlling sterilization cycles and cleanroom environments with zero interruptions. Its diagnostic logs provide audit trails for regulatory inspections.

Related Products

- GE IC697CPU782:

Non-redundant single-slot CPU module, ideal for non-critical applications requiring basic control functionality. - GE IC697CGR772:

Dual-redundant hot-standby CPU module supporting larger I/O configurations (12k discrete points) for mid-level redundancy needs. - GE IC697BEM731:

Genius Fieldbus controller module for connecting up to 30 devices, enabling high-speed data exchange in distributed systems. - GE IC697ACC701:

Lithium battery module providing backup power for memory retention and calendar clock functionality. - GE IC697MEM731N:

512 KB CMOS expansion memory module for increasing program storage capacity in the IC697CPU788. - GE IC697CHS391:

PLC chassis providing power and backplane connectivity for the IC697CPU788 and associated I/O modules. - GE IC697CMM741:

Ethernet interface module enabling TCP/IP communication for remote programming and diagnostics.

Installation and Maintenance

Installation Preparation:

Before installing the GE IC697CPU788, ensure the PLC chassis is properly grounded and powered off. Install three IC697CPU788 modules in adjacent slots, connecting them via the provided synchronization cables. Configure voting parameters using GE’s LogicMaster 90-70 software and verify firmware compatibility with the host system. Connect the IC697ACC701 battery module to retain memory during power outages.

Before installing the GE IC697CPU788, ensure the PLC chassis is properly grounded and powered off. Install three IC697CPU788 modules in adjacent slots, connecting them via the provided synchronization cables. Configure voting parameters using GE’s LogicMaster 90-70 software and verify firmware compatibility with the host system. Connect the IC697ACC701 battery module to retain memory during power outages.

Maintenance Recommendations:

Regularly inspect the IC697CPU788 for loose connections or physical damage, particularly in high-vibration environments. Clean dust from vents using compressed air and replace the IC697ACC701 battery every 5–7 years to maintain memory integrity. Monitor diagnostic LEDs for fault indicators and review controller logs for 异常 synchronization events. Perform quarterly firmware updates to address security patches and enhance compatibility with newer I/O modules. For redundancy testing, simulate processor failures during scheduled downtime to validate system responsiveness.

Regularly inspect the IC697CPU788 for loose connections or physical damage, particularly in high-vibration environments. Clean dust from vents using compressed air and replace the IC697ACC701 battery every 5–7 years to maintain memory integrity. Monitor diagnostic LEDs for fault indicators and review controller logs for 异常 synchronization events. Perform quarterly firmware updates to address security patches and enhance compatibility with newer I/O modules. For redundancy testing, simulate processor failures during scheduled downtime to validate system responsiveness.

Product Assurance

The GE IC697CPU788 is backed by a 1-year warranty covering defects in materials and workmanship. GE provides global technical support, including 24/7 emergency assistance and software updates to ensure compatibility with evolving industry standards. Replacement modules are shipped within 3 days of payment, minimizing downtime in critical applications. With a focus on quality and reliability, GE ensures the IC697CPU788 meets or exceeds performance expectations, supported by its extensive network of certified technicians and spare parts inventory.

For optimal performance, GE recommends annual system audits and adherence to its maintenance guidelines. This comprehensive approach reinforces the IC697CPU788’s reputation as a trusted solution in industrial automation, delivering peace of mind for mission-critical operations.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com