Description

GE IC697CMM741 Single-Slot Ethernet Controller Module

High-Speed Industrial Communication for GE Fanuc Series 90-70 PLC Systems

High-Speed Industrial Communication for GE Fanuc Series 90-70 PLC Systems

Product Overview

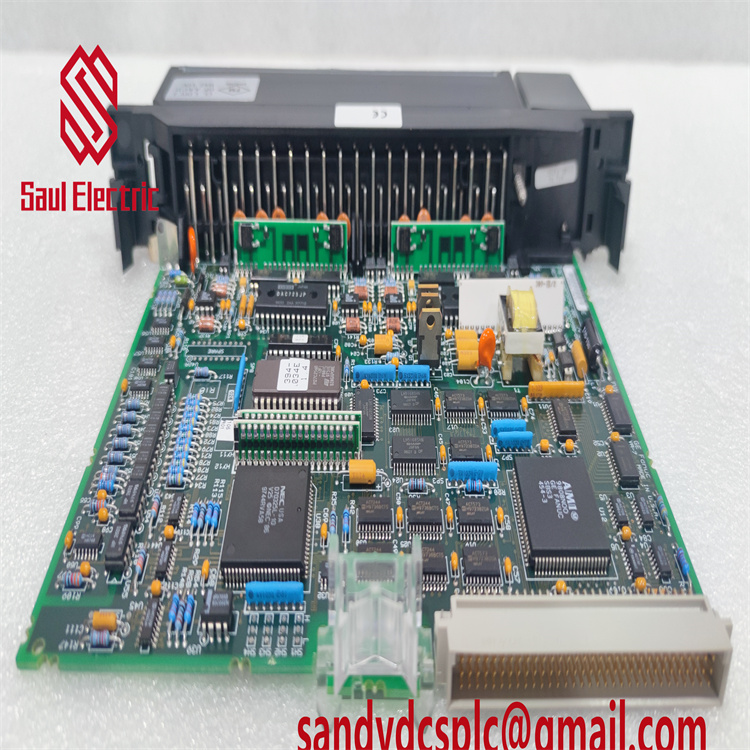

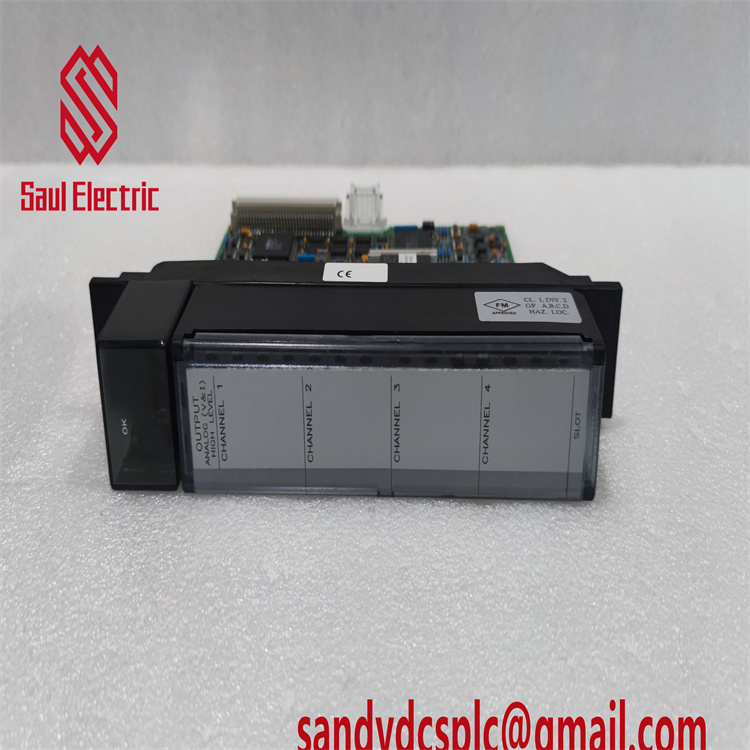

The GE IC697CMM741 is a single-slot Ethernet controller module designed for GE Fanuc Series 90-70 PLC systems, providing high-speed connectivity for industrial automation networks. Unlike its redundant counterparts (e.g., IC697CMM721RR and IC697CMM731RR), the IC697CMM741 focuses on non-critical applications requiring basic Ethernet communication, such as general machine control or data logging. It supports IEEE 802.3 CSMA/CD at 10 Mbps and interfaces with external transceivers via a 15-pin AUI port, enabling flexibility across media types like 10Base5 (thick coaxial), 10Base2 (thin coaxial), and 10BaseT (twisted pair) .

The module’s firmware includes built-in diagnostics and self-test functions, indicated by three front-panel LEDs (Module OK, Online, Status OK). A push-button reset allows quick troubleshooting, while battery-backed RAM ensures program retention during power outages. With a compact single-slot form factor and wide temperature tolerance (-20°C to +60°C), the IC697CMM741 excels in space-constrained or harsh industrial environments .

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | GE IC697CMM741 |

| Manufacturer | General Electric (GE) |

| Product Type | Single-Slot Ethernet Controller Module |

| Compatibility | GE Fanuc Series 90-70 PLC systems |

| Communication Protocols | IEEE 802.3 CSMA/CD (10 Mbps), optional Modbus RTU via converter |

| Ethernet Port | 1 × 15-pin AUI (attachment unit interface) |

| Data Rate | 10 Mbps |

| Microprocessor | 80C186-based embedded controller |

| Power Requirements | +12 VDC ±10% (via backplane), 0.5 A typical |

| Physical Dimensions | 114.3 mm (W) × 233.6 mm (H) × 177.8 mm (D) |

| Weight | 0.6 kg (1.32 lbs) |

| Operating Temperature | -20°C to +60°C |

| EMI/EMC Compliance | EN 61000-6-2 (industrial immunity) |

| Backplane Interface | VMEbus C.1 (40 MB/s data transfer) |

Key Features and Advantages

Flexible Ethernet Connectivity:

The IC697CMM741 supports multiple Ethernet media types via external transceivers, making it suitable for retrofitting legacy systems or bridging to modern networks. For example, it can connect to a 10BaseT network using a twisted-pair transceiver, eliminating the need for costly cabling upgrades .

The IC697CMM741 supports multiple Ethernet media types via external transceivers, making it suitable for retrofitting legacy systems or bridging to modern networks. For example, it can connect to a 10BaseT network using a twisted-pair transceiver, eliminating the need for costly cabling upgrades .

Cost-Effective Non-Redundant Solution:

While not designed for mission-critical environments, the module offers reliable communication for applications like packaging machinery or conveyor systems, where downtime impact is low. Its single-slot design reduces rack space and cost compared to dual-channel redundant modules .

While not designed for mission-critical environments, the module offers reliable communication for applications like packaging machinery or conveyor systems, where downtime impact is low. Its single-slot design reduces rack space and cost compared to dual-channel redundant modules .

Seamless Integration with Series 90-70:

Compatible with GE’s IC697CPU780 and IC697RCM711 redundancy modules, the IC697CMM741 can be paired with other GE components to create hybrid systems. For instance, it can send production data from a Series 90-70 PLC to a modern SCADA system via a Modbus TCP/IP converter .

Compatible with GE’s IC697CPU780 and IC697RCM711 redundancy modules, the IC697CMM741 can be paired with other GE components to create hybrid systems. For instance, it can send production data from a Series 90-70 PLC to a modern SCADA system via a Modbus TCP/IP converter .

Easy Configuration:

Software setup is handled via GE’s Proficy software, which allows users to configure network parameters (e.g., node address, baud rate) without physical jumpers. Firmware updates can be performed remotely, minimizing maintenance downtime .

Software setup is handled via GE’s Proficy software, which allows users to configure network parameters (e.g., node address, baud rate) without physical jumpers. Firmware updates can be performed remotely, minimizing maintenance downtime .

Application Areas

The IC697CMM741 is ideal for industrial scenarios requiring basic Ethernet connectivity:

- Packaging and Material Handling: Coordinating conveyors and labeling machines in food processing plants.

- Machine Tool Control: Enabling remote monitoring of CNC machines in metal fabrication shops.

- HVAC Systems: Integrating building automation systems with PLC-controlled heating/cooling units.

- Data Logging: Collecting production metrics from legacy equipment for predictive maintenance analytics .

Its compatibility with GE’s Genius I/O and GMR (Genius Modular Redundancy) systems makes it a versatile choice for incremental upgrades. For example, it can connect a Series 90-70 PLC to a cloud-based analytics platform via an industrial IoT gateway, extending the system’s lifecycle without replacing core hardware .

Related Products

In stock IC697ACC729 Factory Sealed Plc Programming

IC697ACC744 – GE Fanuc Emerson – PDF Supply

FANUC IC697ACC735 / IC697ACC735

IC697ACC732 Automation Control

GE-Emerson IC697ACC730 Series 90

IC697ACC728 PLC programmable controller micro expansion

FANUC IC697ACC727 / IC697ACC727 (NEW IN BOX)

IC697ACC726 Automation Control

GE Fanuc Emerson Series 90-70 – IC697ACC724

IC697ACC723 Automation Control

Installation and Maintenance

Installation Preparation:

- Power off the PLC rack and install the IC697CMM741 in slots 2–5 of Rack 0.

- Use shielded AUI cables to connect the module to external transceivers, avoiding interference from high-power equipment.

- Configure network settings via Proficy software, ensuring compatibility with the target Ethernet medium (e.g., 10BaseT vs. 10Base2) .

Maintenance Recommendations:

- Routine Checks: Inspect LED status monthly and clean dust from vents quarterly using compressed air.

- Firmware Updates: Periodically update firmware to support new Ethernet standards or security patches.

- Spare Parts Management: Maintain a spare IC697CMM741 for non-critical systems. Test spares annually under simulated load conditions.

Product Assurance

GE guarantees the IC697CMM741 with a 1-year warranty covering defects in materials and workmanship. The module undergoes rigorous testing to achieve an MTBF exceeding 80,000 hours, reflecting its durability in industrial environments.

For technical support, customers gain access to GE’s global network of automation engineers specializing in Series 90-70 systems. Replacement modules are typically available from stock, with delivery within 3–5 days after payment .

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com