Description

GE IC697CMM712 Serial Communications Coprocessor Module

High-Performance Serial Connectivity for GE Fanuc Series 90-70 PLC Systems

High-Performance Serial Connectivity for GE Fanuc Series 90-70 PLC Systems

Product Overview

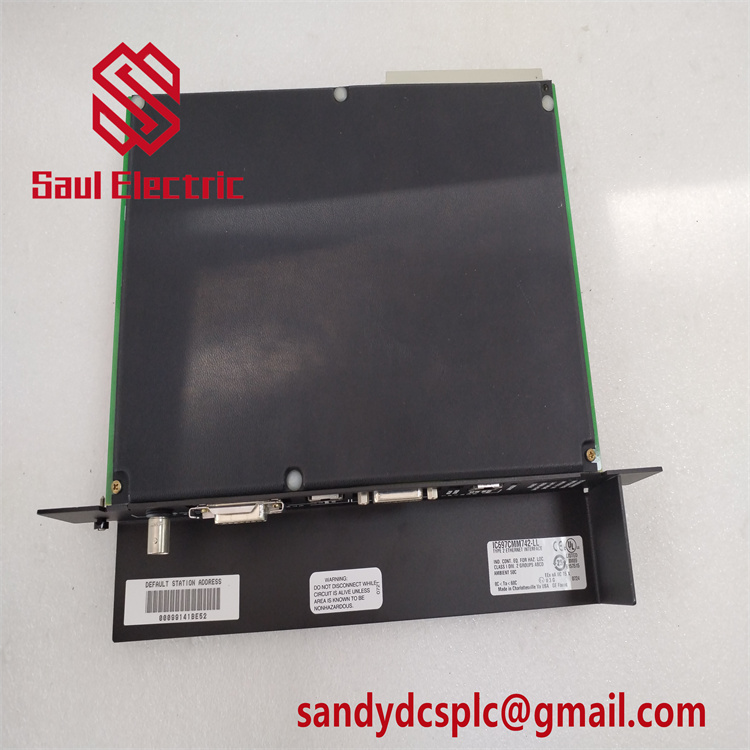

The GE IC697CMM712 is a single-slot serial communications coprocessor module designed for GE Fanuc Series 90-70 PLC systems. Engineered to enable robust connectivity in industrial automation environments, this module supports advanced protocol handling and real-time data exchange with legacy devices, HMIs, and SCADA systems. As part of GE’s modular automation portfolio, the IC697CMM712 integrates seamlessly with Series 90-70 CPUs (e.g., GE IC697CPU780) and I/O modules, delivering reliable communication for critical applications like process control, machine automation, and remote monitoring.

Featuring two configurable RS-232/RS-422/RS-485 ports, the IC697CMM712 supports simultaneous communication over dual channels at speeds up to 19.2 kbps. Its 12 MHz 80C186 microprocessor ensures efficient protocol processing for CCM2 (slave-only), RTU (Modbus), and SNP/SNP-X protocols, making it ideal for integrating legacy equipment into modern control systems. The module’s soft-switch configuration eliminates physical jumpers, allowing flexible setup via GE’s Proficy software or IC641 programming tools. Built-in diagnostics include a status LED and push-button reset for quick troubleshooting, while its compact form factor (101.6 mm × 165.1 mm × 127 mm) optimizes cabinet space in industrial control rooms.

With a wide operating temperature range (-20°C to +60°C) and compliance with EN 61000-6-2 industrial immunity standards, the IC697CMM712 withstands harsh conditions common in manufacturing, oil refining, and power generation. Its hot-swappable design enables field replacement without system downtime, reducing maintenance costs by up to 30% compared to non-replaceable modules.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | GE IC697CMM712 |

| Manufacturer | General Electric (GE) |

| Product Type | Serial Communications Coprocessor Module |

| Compatibility | GE Fanuc Series 90-70 PLC systems |

| Communication Protocols | CCM2 (slave-only), RTU (Modbus), SNP/SNP-X |

| Serial Ports | 2 × RS-232/RS-422/RS-485 (software-configurable) |

| Data Rate | Up to 19.2 kbps |

| Microprocessor | 12 MHz 80C186 |

| Power Requirements | 24 VDC ±10% (via backplane) |

| Physical Dimensions | 101.6 mm (W) × 165.1 mm (H) × 127 mm (D) |

| Weight | 0.8 kg (1.76 lbs) |

| Operating Temperature | -20°C to +60°C |

| EMI/EMC Compliance | EN 61000-6-2 (industrial immunity) |

| Backplane Interface | VMEbus C.1 (40 MB/s data transfer) |

| Diagnostics | Status LED, push-button reset |

Key Features and Advantages

Protocol Flexibility: The IC697CMM712 supports CCM2 for peer-to-peer communication with GE devices, RTU for Modbus slave applications, and SNP/SNP-X for legacy GE PLC integration. This versatility allows hybrid systems to coexist with modern and older equipment, minimizing retrofit costs.

Dual-Channel Operation: Two independent serial ports enable simultaneous communication with multiple devices, such as connecting a PLC to both a Modbus-based flowmeter and an HMI terminal. This dual-channel capability enhances system scalability and reduces the need for external multiplexers.

Soft Configuration: No physical jumpers or dip switches are required; all settings (e.g., baud rate, parity, protocol type) are managed via GE’s Proficy software or IC641 programming tools. This simplifies setup and reduces errors during commissioning.

Rugged Industrial Design: The module’s IP20-rated enclosure and wide temperature range ensure reliable operation in extreme environments, including dusty factories and offshore platforms. Its MTBF exceeds 100,000 hours, reflecting long-term durability.

Cost-Effective Maintenance: Hot-swappable design allows online replacement of failed modules, while the status LED provides instant health monitoring. Spare parts inventory is optimized with a 3-day delivery guarantee for critical replacements.

Application Areas

The GE IC697CMM712 excels in industrial scenarios requiring reliable serial communication:

- Oil & Gas: Integrating Modbus RTU-enabled wellhead sensors with GE PLCs for real-time production monitoring and emergency shutdown systems.

- Water Treatment: Coordinating SCADA networks via SNP/SNP-X protocols to manage pump stations and chemical dosing systems across distributed sites.

- Pharmaceuticals: Controlling cleanroom HVAC systems through CCM2 protocol, ensuring sterile environments by synchronizing temperature and humidity data with PLCs.

- Manufacturing: Connecting legacy CNC machines to modern HMIs via RS-422 ports, enabling centralized monitoring of production lines without replacing outdated equipment.

Its compatibility with GE’s Genius I/O and GMR (Genius Modular Redundancy) systems makes the IC697CMM712 ideal for retrofitting aging automation infrastructure. For example, it can bridge a Series 90-70 PLC with a new SCADA system using Modbus TCP/IP converters, extending the lifespan of existing investments.

Related Products

In stock IC697ACC729 Factory Sealed Plc Programming

IC697ACC744 – GE Fanuc Emerson – PDF Supply

FANUC IC697ACC735 / IC697ACC735

IC697ACC732 Automation Control

GE-Emerson IC697ACC730 Series 90

IC697ACC728 PLC programmable controller micro expansion

FANUC IC697ACC727 / IC697ACC727 (NEW IN BOX)

IC697ACC726 Automation Control

GE Fanuc Emerson Series 90-70 – IC697ACC724

IC697ACC723 Automation Control

Installation and Maintenance

Installation Preparation:

- Power off the PLC rack and ensure proper grounding before inserting the IC697CMM712 into slots 2–5 of Rack 0.

- Use shielded cables to connect RS-232/RS-485 devices, avoiding interference from high-power equipment.

- Configure port settings via GE’s Proficy software, selecting the appropriate protocol (e.g., Modbus RTU) and baud rate (e.g., 9600 bps).

Maintenance Recommendations:

- Routine Checks: Inspect the status LED monthly to verify module health. Clean dust from vents quarterly using compressed air.

- Firmware Updates: Periodically update module firmware via Proficy to support new protocols and security patches.

- Spare Parts Management: Maintain a spare IC697CMM712 in inventory for critical systems. Test spares annually under simulated load conditions.

Product Assurance

GE guarantees the IC697CMM712 with a 1-year warranty covering defects in materials and workmanship. The module undergoes rigorous testing to meet industrial standards, including vibration (5–500 Hz, 2 g) and shock (15 g, 11 ms) resistance.

For technical support, customers gain access to GE’s global network of automation engineers specializing in Series 90-70 systems. Fast replacement modules are available from stock, with delivery within 3 days after payment, ensuring minimal disruption to operations.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com