Description

GE IC697CHS791 9-Slot Front Mount PLC Rack

Engineered for High-Density Industrial Automation Systems

Engineered for High-Density Industrial Automation Systems

Product Overview

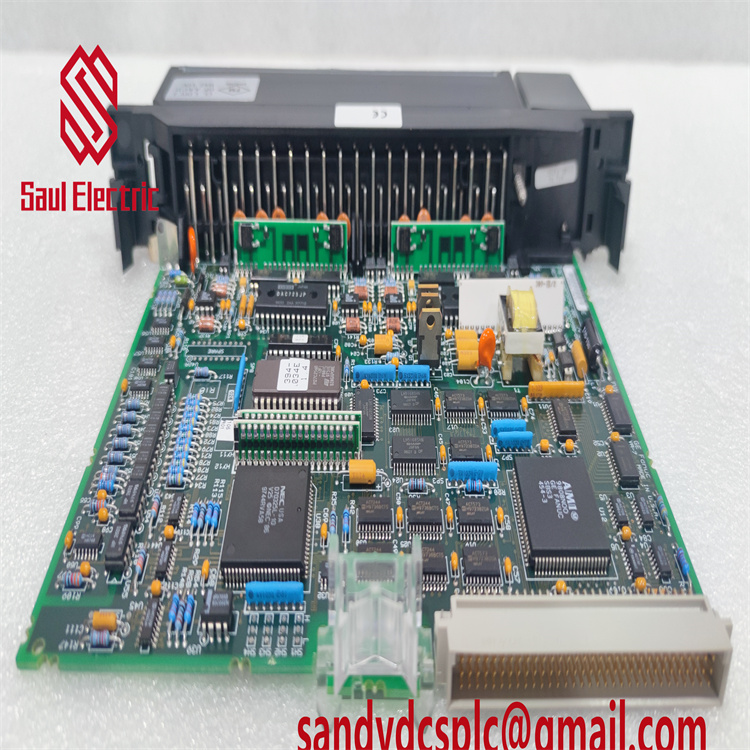

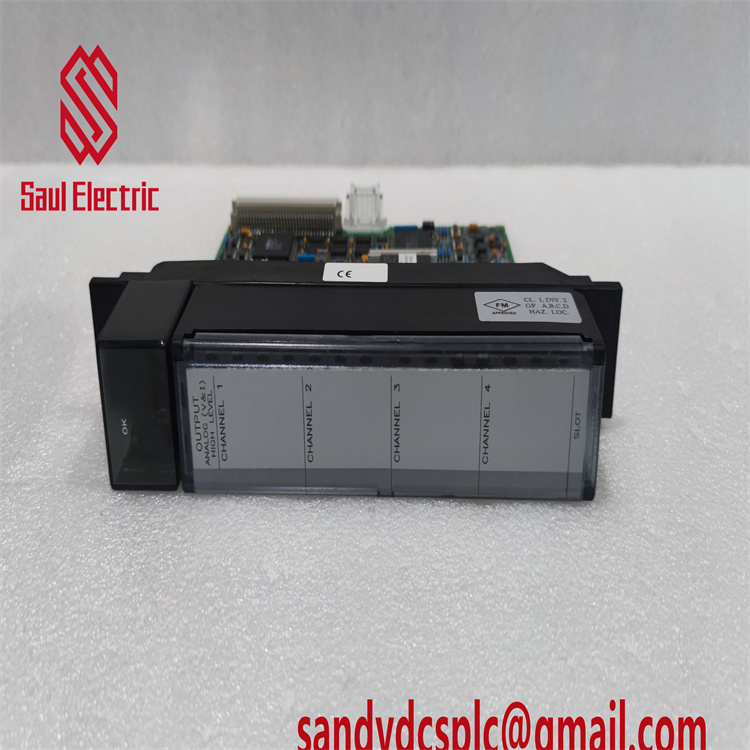

The GE IC697CHS791 is a high-performance 9-slot front mount PLC rack designed for GE Fanuc Series 90-70 industrial control systems. Serving as the foundational infrastructure for modular automation setups, it enables seamless integration of CPU modules, I/O cards, power supplies, and communication processors. Constructed with rugged steel and optimized for space efficiency, the IC697CHS791 supports a wide range of industrial applications requiring reliable mechanical and electrical connectivity.

With a 19-inch standard rack-mount form factor (483 mm width), the IC697CHS791 ensures compatibility with industry-standard enclosures and cabinets. Its front-mount design simplifies module installation and maintenance, while mechanical keys prevent incorrect module insertion. The rack’s backplane supports VMEbus C.1 protocol, enabling high-speed data transfer between modules at rates exceeding 40 MB/s. This makes it ideal for real-time control systems in manufacturing, energy, and process industries.

The IC697CHS791 excels in harsh environments, with a rated operating temperature range of -20°C to +60°C and resistance to electromagnetic interference (EMI) up to 100 V/m. Its modular architecture allows users to scale systems incrementally, adding I/O modules or communication cards as needed without replacing the entire rack. By consolidating multiple components into a single chassis, the IC697CHS791 reduces wiring complexity and minimizes downtime during expansions.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | GE IC697CHS791 |

| Manufacturer | General Electric (GE) |

| Product Type | 9-Slot Front Mount PLC Rack |

| Compatibility | IC697 Series modules (CPU, I/O, power supplies, communication processors) |

| Physical Dimensions | 19″ (483 mm) W × 8.13″ (206 mm) H × 11.9″ (302 mm) D |

| Weight | 9 kg (19.8 lbs) |

| Mounting Method | Panel or DIN rail (with optional brackets) |

| Power Requirements | 24 VDC ±10% (via external power supply) |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Vibration Resistance | 5–500 Hz, 2 g (IEC 60068-2-6) |

| EMI/EMC Compliance | EN 61000-6-2 (industrial immunity) |

| Backplane Protocol | VMEbus C.1 (40 MB/s data transfer) |

Key Features and Advantages

Modular Scalability: The IC697CHS791 accommodates up to 9 modules, allowing users to configure systems from basic I/O control to complex distributed automation. This flexibility supports phased system upgrades and cost-effective capacity planning.

Rugged Construction: Built with heavy-gauge steel and reinforced mounting brackets, the rack withstands shock (15 g, 11 ms) and vibration common in industrial settings. Its IP20-rated enclosure protects against dust and accidental contact.

Easy Maintenance: Front-accessible module slots enable tool-free replacements, reducing mean time to repair (MTTR) by up to 50% compared to rear-mount designs. LED indicators on each module provide real-time status monitoring.

Space Efficiency: The 19-inch form factor fits standard industrial cabinets, optimizing floor space in control rooms or machine enclosures. Optional side panels further enhance EMI shielding.

Cost-Effective Expansion: By reusing the IC697CHS791 chassis for system upgrades, users avoid replacing entire racks, lowering total cost of ownership (TCO) by 20–30% over traditional fixed-configuration systems.

Application Areas

The GE IC697CHS791 is widely deployed in industries requiring reliable, scalable automation solutions:

- Manufacturing: Powering assembly lines with mixed I/O configurations for robotics, conveyor systems, and quality control sensors. For example, in automotive plants, the rack supports real-time coordination of welding robots and vision inspection systems.

- Oil & Gas: Enabling distributed control in offshore platforms by hosting redundant CPUs and high-density analog I/O modules for monitoring pressure and flow.

- Water Treatment: Managing pump control, chemical dosing, and SCADA integration in wastewater treatment plants through modular I/O expansions.

- Energy: Supporting power generation systems by combining CPU modules with specialized communication cards for grid synchronization and predictive maintenance.

Its compatibility with legacy GE Fanuc Series 90-70 modules makes the IC697CHS791 ideal for retrofitting aging systems without replacing existing software or field devices.

Related Products

In stock IC697ACC729 Factory Sealed Plc Programming

IC697ACC744 – GE Fanuc Emerson – PDF Supply

FANUC IC697ACC735 / IC697ACC735

IC697ACC732 Automation Control

GE-Emerson IC697ACC730 Series 90

IC697ACC728 PLC programmable controller micro expansion

FANUC IC697ACC727 / IC697ACC727 (NEW IN BOX)

IC697ACC726 Automation Control

GE Fanuc Emerson Series 90-70 – IC697ACC724

IC697ACC723 Automation Control

Installation and Maintenance

Installation Preparation:

Ensure the mounting surface is flat and grounded. The IC697CHS791 can be secured using either DIN rail clips or panel-mount screws. Verify power supply compatibility (24 VDC) and route cables through the rear cable management channels to minimize EMI.

Ensure the mounting surface is flat and grounded. The IC697CHS791 can be secured using either DIN rail clips or panel-mount screws. Verify power supply compatibility (24 VDC) and route cables through the rear cable management channels to minimize EMI.

Maintenance Recommendations:

- Routine Checks: Inspect module connections quarterly and clean dust from vents using compressed air.

- Firmware Updates: Periodically update backplane firmware via GE’s Proficy software to ensure compatibility with new modules.

- Spare Parts Management: Maintain a spare IC697CHS791 in inventory for critical systems. Test spare racks annually under simulated load conditions.

Product Assurance

GE stands behind the IC697CHS791 with a 1-year warranty covering defects in materials and workmanship. The rack undergoes rigorous testing to achieve an MTBF exceeding 100,000 hours, reflecting its durability in industrial environments.

For technical support, customers gain access to GE’s global network of automation engineers specializing in Series 90-70 systems. Fast replacement racks are available from stock, with delivery within 3 days after payment, ensuring minimal disruption to operations.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com