Description

Product Overview

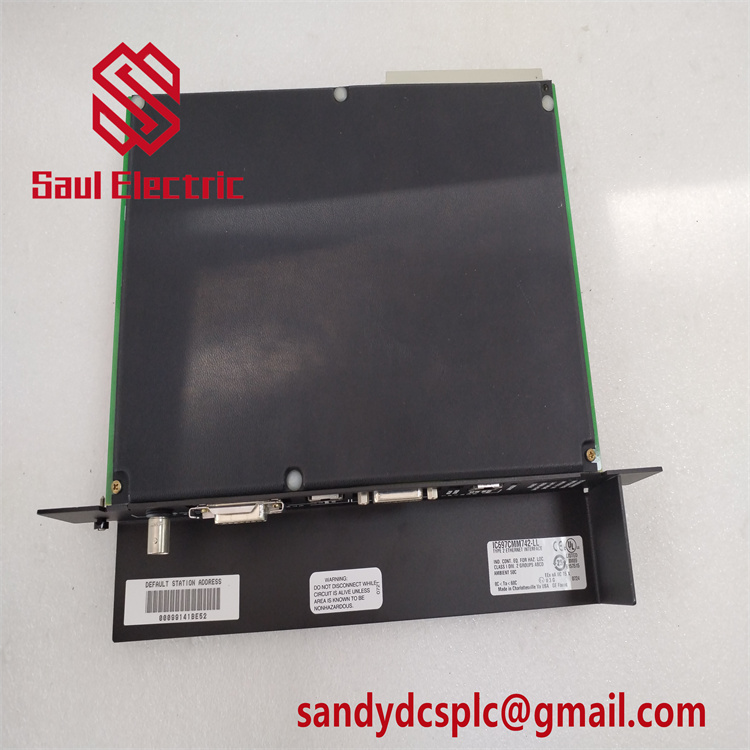

The GE IC697CHS771 is a 12-slot Dual Redundant Front Mount I/O Rack designed for mission-critical industrial automation systems, belonging to the GE Fanuc Series 90-70 platform. This advanced rack combines modular flexibility with high availability, making it ideal for applications where downtime is unacceptable. The IC697CHS771 supports dual power supply inputs and redundant communication pathways, ensuring continuous operation in environments such as power generation, oil refineries, and chemical processing plants.

The GE IC697CHS771 is a 12-slot Dual Redundant Front Mount I/O Rack designed for mission-critical industrial automation systems, belonging to the GE Fanuc Series 90-70 platform. This advanced rack combines modular flexibility with high availability, making it ideal for applications where downtime is unacceptable. The IC697CHS771 supports dual power supply inputs and redundant communication pathways, ensuring continuous operation in environments such as power generation, oil refineries, and chemical processing plants.

Featuring a front-mount design, the IC697CHS771 optimizes accessibility for module replacement and maintenance while accommodating all IC697 PLC modules, including CPUs, I/O cards, and communication processors. Its VMEbus architecture enables high-speed data transfer between modules, ensuring real-time response in demanding scenarios. The rack’s slot sensing technology eliminates manual addressing, streamlining installation and reducing configuration errors. With support for both AC and DC power inputs, the IC697CHS771 offers flexibility in power sourcing, while its redundant power supply capability (via IC697PWR713RR) ensures continuous operation even during power fluctuations or failures.

In industrial settings, the IC697CHS771 serves as the backbone of distributed control systems (DCS), enabling seamless integration with SCADA and other higher-level systems. Its rugged construction withstands extreme temperatures, vibrations, and electromagnetic interference, ensuring reliable performance in harsh environments. By consolidating multiple modules into a single enclosure, the rack reduces cabling complexity and enhances system maintainability. The IC697CHS771 also supports third-party VME modules, allowing integration of specialized components while adhering to GE Fanuc’s strict compatibility guidelines .

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC697CHS771 |

| Manufacturer | GE Fanuc |

| Product Type | 12-slot Dual Redundant Front Mount I/O Rack |

| Module Compatibility | All IC697 PLC modules and IC687 VME modules |

| Power Supply | Dual AC/DC inputs (via IC697PWR713RR) |

| Backplane Bus | VME C.1 Standard with Redundant Pathways |

| Slot Configuration | 2 power supply slots + 12 backplane slots (6 per section) |

| Dimensions | 19” (W) x 13.4” (H) x 11.8” (D) |

| Weight | 44 lbs (20 kg) |

| Operating Temperature | 0°C to 55°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Mounting Orientation | Front-panel mount |

| Communication Protocols | Ethernet, Modbus, RS-485 (Dual Ports) |

| Redundancy Features | Dual power inputs, redundant communication |

| 防护等级 | IP54 |

| Backplane Spacing | 0.8” centers (VME-compliant) |

Key Features and Advantages

Dual Power Redundancy: The IC697CHS771 supports two independent power supply inputs, ensuring continuous operation even if one power source fails. This feature is critical in applications like offshore platforms and nuclear facilities, where power interruptions could lead to catastrophic consequences.

Dual Power Redundancy: The IC697CHS771 supports two independent power supply inputs, ensuring continuous operation even if one power source fails. This feature is critical in applications like offshore platforms and nuclear facilities, where power interruptions could lead to catastrophic consequences.

Redundant Communication: Equipped with dual Ethernet and RS-485 ports, the rack enables failover communication between control systems. This redundancy minimizes data loss and ensures uninterrupted monitoring and control.

Modular Flexibility: The rack accommodates up to 12 I/O modules (6 per section), allowing users to scale systems from basic control to advanced automation. Its VMEbus architecture supports high-speed data transfer rates, making it suitable for real-time applications like turbine control and robotics. The front-mount design simplifies module replacement without disturbing adjacent components, reducing mean time to repair (MTTR).

Rugged Design: Built with industrial-grade materials, the IC697CHS771 withstands extreme temperatures, humidity, and vibrations. Its IP54-rated enclosure protects against dust and water ingress, ensuring reliable performance in harsh environments.

Third-Party Module Support: The rack’s 0.8” backplane spacing complies with VME standards, enabling integration of third-party modules while maintaining compatibility with GE Fanuc’s IC697 series. This flexibility is particularly valuable in hybrid automation systems requiring specialized components .

Applications

The IC697CHS771 is specifically engineered for industries requiring high availability and modular scalability:

The IC697CHS771 is specifically engineered for industries requiring high availability and modular scalability:

- Power Generation: Ensuring continuous operation of steam turbines, generators, and boiler control systems.

- Oil and Gas: Safeguarding offshore platforms, refineries, and pipeline monitoring systems.

- Chemical Processing: Managing reactors, distillation columns, and safety interlock systems.

- Pharmaceuticals: Maintaining sterile environments and critical process control in manufacturing.

- Transportation: Supporting rail and subway systems with fail-safe control mechanisms.

- Hybrid Automation: Integrating third-party VME modules into GE Fanuc PLC systems for specialized applications like high-speed data acquisition or custom control logic .

By combining redundancy with modularity, the IC697CHS771 reduces mean time to repair (MTTR) and extends mean time between failures (MTBF), delivering a low total cost of ownership.

Related Products

In stock IC697ACC729 Factory Sealed Plc Programming

IC697ACC744 – GE Fanuc Emerson – PDF Supply

FANUC IC697ACC735 / IC697ACC735

IC697ACC732 Automation Control

GE-Emerson IC697ACC730 Series 90

IC697ACC728 PLC programmable controller micro expansion

FANUC IC697ACC727 / IC697ACC727 (NEW IN BOX)

IC697ACC726 Automation Control

GE Fanuc Emerson Series 90-70 – IC697ACC724

IC697ACC723 Automation Control

Installation and Maintenance

Pre-Installation Preparation:

Ensure the control panel is properly grounded and ventilated. Verify the IC697CHS771 dimensions (19” W x 13.4” H x 11.8” D) fit the enclosure. Install dual power supply modules (IC697PWR713RR) in the leftmost slots and secure all modules with captive screws. Use shielded cables for I/O connections to minimize interference. For third-party VME modules, follow GE Fanuc’s integration guidelines outlined in the user manual .

Pre-Installation Preparation:

Ensure the control panel is properly grounded and ventilated. Verify the IC697CHS771 dimensions (19” W x 13.4” H x 11.8” D) fit the enclosure. Install dual power supply modules (IC697PWR713RR) in the leftmost slots and secure all modules with captive screws. Use shielded cables for I/O connections to minimize interference. For third-party VME modules, follow GE Fanuc’s integration guidelines outlined in the user manual .

Maintenance Recommendations:

Regularly inspect the rack for loose connections or physical damage. Use GE Fanuc’s Configurator software to monitor power supply health and communication link status. Perform annual calibration checks for analog modules and replace batteries in memory modules (e.g., IC697MEM715) every 2–3 years. Test power supply failover and communication redundancy annually to ensure operational integrity. For third-party modules, consult the respective manufacturer’s maintenance protocols .

Regularly inspect the rack for loose connections or physical damage. Use GE Fanuc’s Configurator software to monitor power supply health and communication link status. Perform annual calibration checks for analog modules and replace batteries in memory modules (e.g., IC697MEM715) every 2–3 years. Test power supply failover and communication redundancy annually to ensure operational integrity. For third-party modules, consult the respective manufacturer’s maintenance protocols .

Product Warranty

The IC697CHS771 comes with a 1-year warranty covering defects in materials and workmanship. We offer 24/7 technical support and a 3-day delivery guarantee for in-stock orders. Our global service network ensures rapid response to maintenance requests, minimizing downtime.

The IC697CHS771 comes with a 1-year warranty covering defects in materials and workmanship. We offer 24/7 technical support and a 3-day delivery guarantee for in-stock orders. Our global service network ensures rapid response to maintenance requests, minimizing downtime.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com