Description

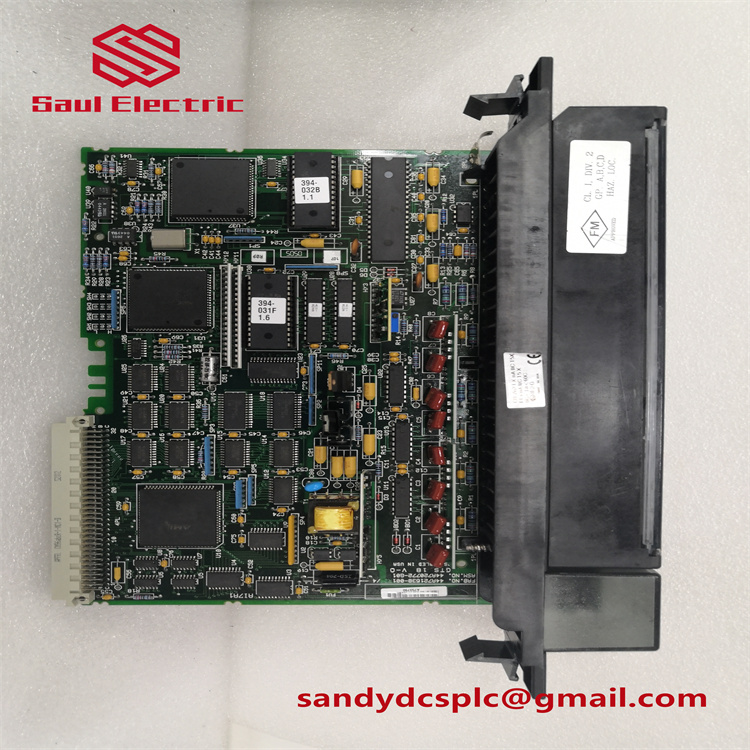

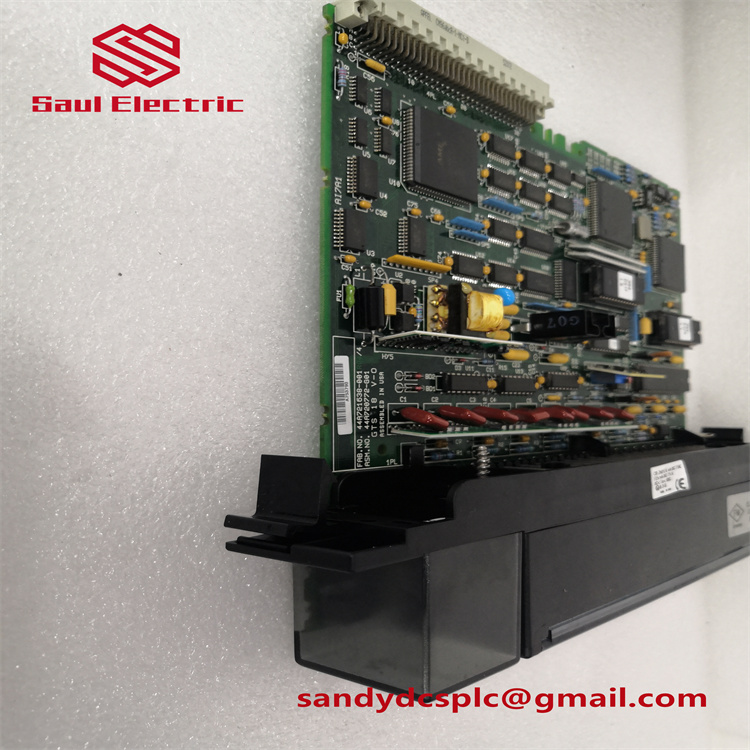

GE IC697BEM713

Product Overview

The GE IC697BEM713 is a critical bus extension module within GE Fanuc’s Series 90-70 PLC platform, designed to expand system scalability by connecting additional I/O racks to the main CPU rack. It enables bidirectional data transmission between the central controller and remote I/O units, enhancing the PLC’s capacity for complex automation tasks. With robust industrial-grade design, the GE IC697BEM713 supports high-speed communication (500 KB/s) and seamless integration into existing GE 90-70 infrastructures, making it indispensable for distributed control systems requiring flexible I/O expansion .

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC697BEM713 |

| Manufacturer | GE (Emerson Automation) |

| Product Type | Bus Transmitter Module |

| Bus Interface | Parallel interface (500 KB/s) |

| Network Protocols | TCP/IP, UDP/IP, Modbus/TCP |

| I/O Expansion | Supports up to 7 additional PLC racks |

| Input Voltage | 24V DC ±5% |

| Operating Temperature | 0°C to 60°C |

| Protection Rating | IP20 (requires control cabinet installation) |

| Dimensions | 160 mm × 80 mm × 45 mm |

| Hot-Swap Support | Yes (compatible configurations) |

Note: Conflicting input current specs (1A max in ) may refer to auxiliary power; primary function is bus extension.

Key Features and Advantages

High-Speed Data Transmission:

The GE IC697BEM713 achieves 500 KB/s parallel data transfer, minimizing latency in critical applications like production line synchronization. Its dual-interface design (top for programming, bottom for bus expansion) simplifies system topology .

Robust Industrial Compatibility:

Supporting Modbus/TCP and Genius bus protocols, the module integrates seamlessly with GE’s Proficy Machine Edition (PME) software. Optical isolation ensures signal integrity in electromagnetically noisy environments (e.g., welding plants) .

Scalability and Ease of Installation:

With DIN-rail mounting and hot-swap capability, the IC697BEM713 allows rapid expansion without halting operations. Its modular design reduces downtime during maintenance or upgrades .

Application Areas

Distributed Manufacturing Systems:

In automotive assembly lines, the GE IC697BEM713 links robotic workstations to central controllers, enabling real-time coordination of welding arms and conveyor belts. Its tolerance for temperature fluctuations (0–60°C) suits unheated factory floors .

Energy and Infrastructure:

For substation monitoring, the module aggregates I/O data from remote sensors (e.g., grid voltage detectors), transmitting via Modbus/TCP to SCADA systems. IP20 protection ensures reliability in dusty electrical rooms .

Process Industries:

In chemical plants, it extends control to hazardous-area I/O racks (e.g., tank-level sensors), with bidirectional data flow enabling closed-loop valve adjustments .

Related Products

In stock IC697ACC729 Factory Sealed Plc Programming

IC697ACC744 – GE Fanuc Emerson – PDF Supply

FANUC IC697ACC735 / IC697ACC735

IC697ACC732 Automation Control

GE-Emerson IC697ACC730 Series 90

IC697ACC728 PLC programmable controller micro expansion

FANUC IC697ACC727 / IC697ACC727 (NEW IN BOX)

IC697ACC726 Automation Control

GE Fanuc Emerson Series 90-70 – IC697ACC724

IC697ACC723 Automation Control

Installation and Maintenance

Installation Prep: Mount vertically in the CPU rack’s Slot 2 per GE guidelines . Verify 24V DC power stability (±5%) and ground resistance ≤0.1Ω .

Maintenance Tips: Clean air vents quarterly with dry compressed air. Monitor “Fault” LED: steady red indicates hardware failure; flashing suggests bus communication errors. Replace every 8–10 years or after 100,000 power cycles .

Product Assurance

The GE IC697BEM713 includes a 1-year global warranty against defects. GE Emerson provides lifetime technical support via its service portal, with critical spare parts guaranteed for 10 years post-discontinuation. On-site troubleshooting is available within 48 hours for mission-critical failures .

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com