Description

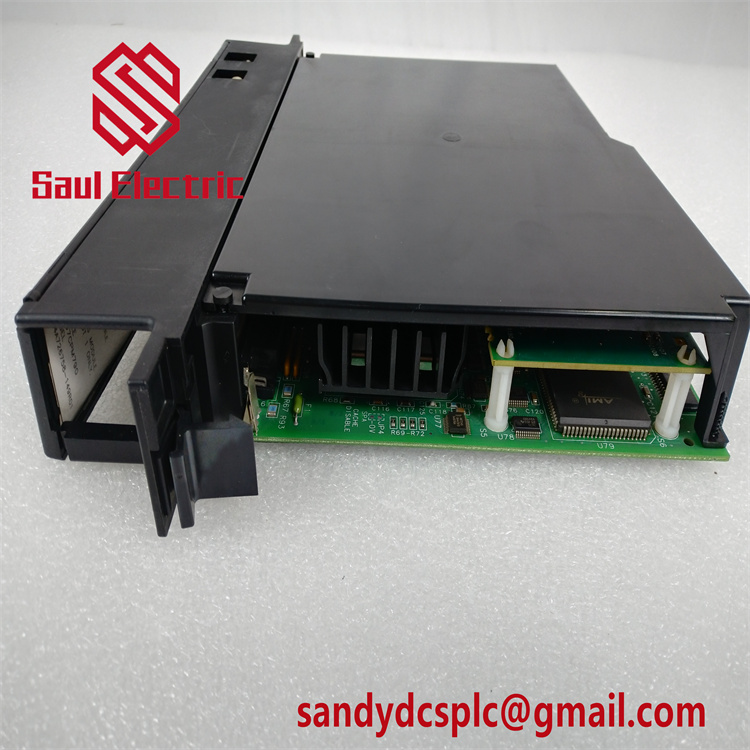

GE IC697BEM711

Product Overview

The GE IC697BEM711 is a high-performance bus expansion module designed to extend the I/O capacity of GE Series 90-70 PLC systems, a critical component in industrial automation for scaling complex control architectures. As a key member of GE’s IC697BEM series, the IC697BEM711 enables seamless integration of additional analog and digital modules, supporting up to 120 I/O points when paired with compatible expander modules like the IC697ALG440. This module acts as a bridge between the PLC’s central processing unit (CPU) and distributed I/O, ensuring high-speed data transmission via its VME backplane interface.

Engineered for rugged reliability, the GE IC697BEM711 operates across a wide temperature range (-40°C to +85°C) and features robust electromagnetic interference (EMI) protection, making it suitable for harsh industrial environments such as chemical plants and power generation facilities. Its hot-swappable design allows for maintenance without system shutdown, minimizing downtime in mission-critical applications. With software-based configuration via GE’s Proficy Machine Edition, the IC697BEM711 simplifies system setup, ensuring compatibility with legacy and modern Series 90-70 components alike.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC697BEM711 |

| Manufacturer | GE |

| Product Type | Bus Expansion Module for Series 90-70 PLCs |

| Expansion Capacity | Supports up to 120 I/O points with compatible expander modules |

| Communication Interface | VME backplane (32-bit data bus) |

| Power Requirements | 5V DC (1.2A max, shared with connected modules) |

| Operating Temperature | -40°C to +85°C (-40°F to 185°F) |

| Humidity | 5% to 95% non-condensing |

| Protection Rating | IP20 (with optional IP65 enclosure for harsh environments) |

| Dimensions | 118 mm x 70 mm x 25 mm (4.65″ x 2.75″ x 0.98″) |

| Weight | 0.35 kg (0.77 lbs) |

| Hot-Swap Support | Yes (without system shutdown) |

| Compatibility | GE Series 90-70 PLCs, IC697ALG and IC697MDL expander modules |

Main Features and Advantages

Scalable expansion: The IC697BEM711 enables flexible I/O scaling, supporting up to 120 points when paired with modules like the IC697ALG440 (analog) and IC697MDL240 (digital). This scalability is ideal for growing industrial systems, from small manufacturing cells to large-scale process plants.

High-speed communication: Its VME backplane interface ensures data transfer rates of up to 40 MB/s, critical for real-time control applications such as high-speed packaging lines or power grid management.

Rugged design: Built to withstand extreme temperatures, vibrations, and EMI, the IC697BEM711 operates reliably in harsh settings, reducing maintenance costs in sectors like mining and offshore oil & gas.

Hot-swappable capability: The module can be replaced during operation, minimizing downtime in mission-critical systems—an essential feature for industries where production halts are costly.

Seamless integration: Compatible with all GE Series 90-70 PLCs and Proficy Machine Edition software, the IC697BEM711 integrates effortlessly into existing systems, extending their lifespan without requiring full upgrades.

Application Areas

The GE IC697BEM711 is widely used in industries requiring scalable automation:

- Manufacturing: Expands I/O capacity in automotive assembly lines to monitor robotic arms, conveyor belts, and quality control sensors.

- Power Generation: Extends control systems in thermal plants to manage turbine sensors, cooling systems, and generator outputs.

- Chemical Processing: Scales I/O for monitoring reactor pressure, temperature, and chemical dosing in corrosive environments.

- Water/Wastewater: Supports additional sensors for pump control, flow meters, and treatment process monitoring in municipal facilities.

- Oil & Gas: Enables I/O expansion in offshore platforms to track wellhead pressure, pipeline flow, and safety systems.

Its ability to scale systems incrementally makes it a cost-effective solution for both new installations and retrofits of aging industrial infrastructure.

Related Products

In stock IC697ACC729 Factory Sealed Plc Programming

IC697ACC744 – GE Fanuc Emerson – PDF Supply

FANUC IC697ACC735 / IC697ACC735

IC697ACC732 Automation Control

GE-Emerson IC697ACC730 Series 90

IC697ACC728 PLC programmable controller micro expansion

FANUC IC697ACC727 / IC697ACC727 (NEW IN BOX)

IC697ACC726 Automation Control

GE Fanuc Emerson Series 90-70 – IC697ACC724

IC697ACC723 Automation Control

Installation and Maintenance

Installation preparation: Power down the PLC system and ensure proper grounding. Use electrostatic discharge (ESD) protection when handling the IC697BEM711. Insert the module into an available slot in the Series 90-70 rack, securing it with retention clips. Connect expander modules via the VME backplane and configure expansion parameters using Proficy Machine Edition. Verify communication with the CPU before powering up the full system.

Maintenance recommendations: Inspect the IC697BEM711 quarterly for loose connections or dust buildup, cleaning with a dry anti-static cloth. Check status LEDs regularly to monitor power and communication health. For hot-swap replacement, ensure the system is in a safe state before removing the module. Replace the module’s internal battery (if equipped) every 5–7 years to maintain configuration data during power outages.

Product Assurance

The GE IC697BEM711 is backed by a 1-year warranty covering defects in materials and workmanship. Rigorously tested to meet industrial standards (IEC 61131-2, UL 508), it ensures reliable performance in critical applications. Technical support is available 24/7 to assist with installation, troubleshooting, and firmware updates, ensuring the IC697BEM711 operates optimally throughout its lifecycle.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com