Description

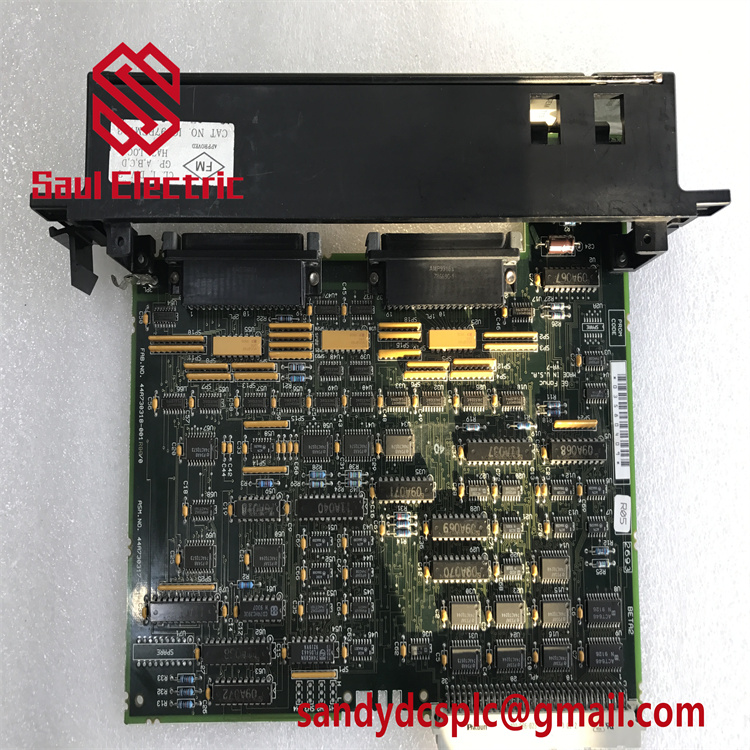

GE IC697ALG440

Product Overview

The GE IC697ALG440 is a high-performance analog input expander module designed for industrial automation systems, specifically engineered to expand the analog signal processing capabilities of GE Series 90-70 PLCs. As part of GE’s robust I/O portfolio, the IC697ALG440 provides 16 individually configurable differential inputs for voltage (-10V to +10V DC) or current (4-20 mA) signals, enabling precise data acquisition in critical applications such as process control, energy management, and machinery monitoring.

The GE IC697ALG440 is a high-performance analog input expander module designed for industrial automation systems, specifically engineered to expand the analog signal processing capabilities of GE Series 90-70 PLCs. As part of GE’s robust I/O portfolio, the IC697ALG440 provides 16 individually configurable differential inputs for voltage (-10V to +10V DC) or current (4-20 mA) signals, enabling precise data acquisition in critical applications such as process control, energy management, and machinery monitoring.

With 16-bit resolution and factory-calibrated accuracy (±0.01% of full scale for voltage inputs), the IC697ALG440 ensures reliable conversion of analog signals into digital data for real-time analysis by the PLC’s CPU. Its software-based configuration (compatible with GE’s Proficy Machine Edition) eliminates physical jumpers, while the removable 40-pin terminal block simplifies field wiring. The module’s VME backplane interface seamlessly integrates with GE Series 90-70/30 systems, supporting up to 120 total inputs when paired with base converter modules like the GE IC697ALG230. Designed to operate in harsh environments, the IC697ALG440 withstands temperatures ranging from -40°C to +85°C and features transient overvoltage protection, making it ideal for offshore platforms, chemical plants, and power generation facilities.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC697ALG440 |

| Manufacturer | GE |

| Product Type | 16-Channel Analog Input Expander Module |

| Input Channels | 16 differential (configurable for voltage/current) |

| Voltage Range | -10V to +10V DC |

| Current Range | 4-20 mA |

| Resolution | 16-bit with 14-bit monotonicity |

| Accuracy | Voltage: ±0.01% of full scale; Current: ±0.05% of full scale |

| Power Requirements | 5V DC (shared with base converter module) |

| Communication Interface | VME backplane |

| Isolation | 500V RMS (inputs isolated from backplane) |

| Operating Temperature | -40°C to +85°C (-40°F to 185°F) |

| Humidity | 5% to 95% non-condensing |

| Protection Rating | IP65 (with optional enclosure) |

| Dimensions | 118 mm x 70 mm x 25 mm (4.65″ x 2.75″ x 0.98″) |

| Weight | 0.38 kg (0.84 lbs) |

Main Features and Advantages

High-channel density: The IC697ALG440’s 16-channel design reduces rack space and cabling complexity compared to lower-channel modules, optimizing system layouts in space-constrained environments like manufacturing floors and control rooms.

High-channel density: The IC697ALG440’s 16-channel design reduces rack space and cabling complexity compared to lower-channel modules, optimizing system layouts in space-constrained environments like manufacturing floors and control rooms.

Precision signal conditioning: With 16-bit resolution and tight accuracy, the module ensures reliable data acquisition for applications requiring fine-tuned measurements, such as pharmaceutical ingredient dosing or semiconductor wafer inspection. Its self-calibration feature minimizes drift over time, reducing maintenance costs.

Rugged reliability: Built to withstand extreme temperatures and transient voltage spikes, the IC697ALG440 excels in harsh industrial settings. Its redundant power paths and fault-tolerant communication architecture (when paired with GE’s redundancy modules) ensure continuous operation in safety-critical scenarios.

Flexible scalability: The module integrates seamlessly with GE’s Series 90-70/30 PLCs, allowing expansion of analog input capacity up to 120 channels. This scalability is ideal for projects requiring incremental system upgrades or complex multi-loop control.

Application Areas

The GE IC697ALG440 is widely used in industries where accurate analog data acquisition is essential:

The GE IC697ALG440 is widely used in industries where accurate analog data acquisition is essential:

- Process Manufacturing: Monitors pressure, temperature, and flow rates in chemical reactors and distillation columns, enabling real-time adjustments to maintain product quality.

- Oil & Gas: Measures wellhead pressure and pipeline flow in offshore platforms, ensuring compliance with environmental regulations and optimizing production efficiency.

- Power Generation: Collects data from turbines and generators to optimize energy output and diagnose equipment faults in thermal and nuclear power plants.

- Water Treatment: Regulates chemical dosing systems and monitors contaminant levels in wastewater treatment facilities, ensuring regulatory compliance.

- Aerospace: Supports precision testing of aircraft components by capturing high-resolution sensor data in wind tunnels and engine test cells.

Related Products

In stock IC697ACC729 Factory Sealed Plc Programming

IC697ACC744 – GE Fanuc Emerson – PDF Supply

FANUC IC697ACC735 / IC697ACC735

IC697ACC732 Automation Control

GE-Emerson IC697ACC730 Series 90

IC697ACC728 PLC programmable controller micro expansion

FANUC IC697ACC727 / IC697ACC727 (NEW IN BOX)

IC697ACC726 Automation Control

GE Fanuc Emerson Series 90-70 – IC697ACC724

IC697ACC723 Automation Control

Installation and Maintenance

Installation before preparation: Power down the PLC system and ensure proper grounding. Use electrostatic discharge (ESD) protection when handling the IC697ALG440. Connect the module to the VME backplane and wire inputs to sensors using shielded cables to minimize noise interference. Configure channel parameters (signal type, scaling) via Proficy Machine Edition, and verify communication with the base converter module.

Installation before preparation: Power down the PLC system and ensure proper grounding. Use electrostatic discharge (ESD) protection when handling the IC697ALG440. Connect the module to the VME backplane and wire inputs to sensors using shielded cables to minimize noise interference. Configure channel parameters (signal type, scaling) via Proficy Machine Edition, and verify communication with the base converter module.

Maintenance recommendations: Inspect wiring connections quarterly for corrosion or looseness. Clean the IC697ALG440 with a dry, anti-static cloth to prevent dust buildup. Replace the IC697ACC701 battery every 5-7 years to maintain memory retention. Monitor status LEDs monthly for power or communication faults, and recalibrate inputs annually using GE-certified equipment to ensure accuracy.

Product Assurance

The GE IC697ALG440 is backed by a 1-year warranty covering defects in materials and workmanship. Rigorously tested to meet industrial standards (IEC 61131-2, UL 508), the module ensures reliable performance in critical applications. GE’s global technical support network provides 24/7 assistance for installation, troubleshooting, and firmware updates, ensuring optimal operation throughout the module’s lifecycle.

The GE IC697ALG440 is backed by a 1-year warranty covering defects in materials and workmanship. Rigorously tested to meet industrial standards (IEC 61131-2, UL 508), the module ensures reliable performance in critical applications. GE’s global technical support network provides 24/7 assistance for installation, troubleshooting, and firmware updates, ensuring optimal operation throughout the module’s lifecycle.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com