Description

Product Overview

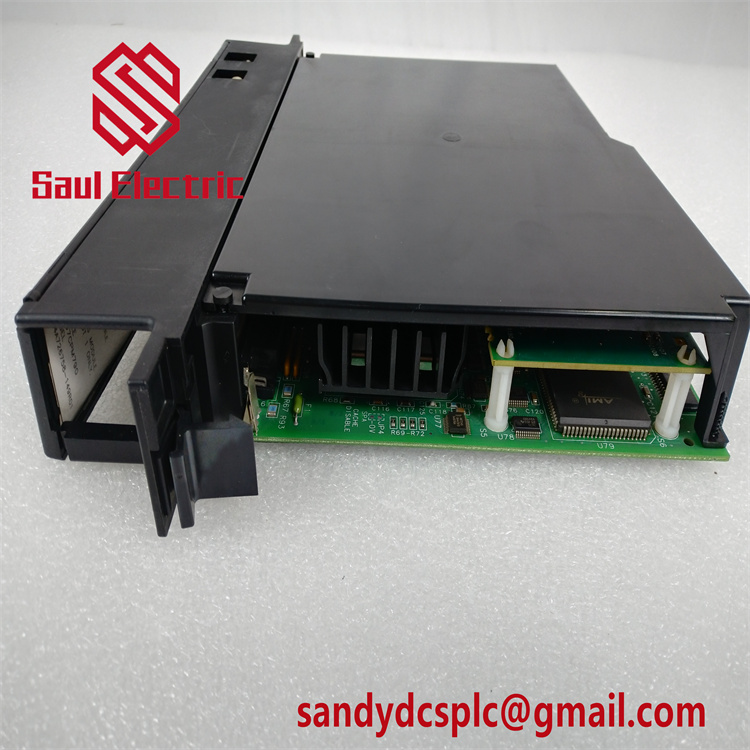

The GE Fanuc IC697ALG234 is a high-density analog input module designed for advanced process control in GE Series 90-70 PLC systems. As a 16-channel variant of the IC697ALG230 base module, it delivers precision data acquisition with enhanced scalability, making it ideal for large-scale industrial applications requiring simultaneous monitoring of multiple analog signals. The IC697ALG234 supports differential voltage (-10V to +10V) and current (4-20 mA) inputs, offering a base resolution of 14 bits that can be extended to 16 bits via oversampling techniques. This module integrates seamlessly with GE’s VME backplane architecture, enabling real-time data transfer to PLC CPUs for critical decision-making in environments like chemical plants, power generation facilities, and water treatment systems.

The GE Fanuc IC697ALG234 is a high-density analog input module designed for advanced process control in GE Series 90-70 PLC systems. As a 16-channel variant of the IC697ALG230 base module, it delivers precision data acquisition with enhanced scalability, making it ideal for large-scale industrial applications requiring simultaneous monitoring of multiple analog signals. The IC697ALG234 supports differential voltage (-10V to +10V) and current (4-20 mA) inputs, offering a base resolution of 14 bits that can be extended to 16 bits via oversampling techniques. This module integrates seamlessly with GE’s VME backplane architecture, enabling real-time data transfer to PLC CPUs for critical decision-making in environments like chemical plants, power generation facilities, and water treatment systems.

Engineered with a removable 40-pin terminal block and soft configuration (no jumpers/dip switches), the IC697ALG234 simplifies field wiring and system customization. Its error-correcting code (ECC) memory ensures data integrity during transient voltage fluctuations, while the -40°C to +85°C operating range and IP65-rated enclosure (optional) guarantee reliable performance in harsh industrial settings. By combining with expander modules like the IC697ALG440 (current) or IC697ALG441 (voltage), the system can scale to 120 analog inputs, making it a cost-effective solution for complex automation scenarios.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC697ALG234 |

| Manufacturer | GE Fanuc |

| Product Type | High-Density Analog Input Module |

| Input Channels | 16 differential (configurable for voltage/current) |

| Voltage Range | -10V to +10V DC |

| Current Range | 4-20 mA (with internal load resistors) |

| Resolution | 14-bit base (16-bit via oversampling) |

| Power Requirements | 5V DC (1.5A per module) |

| Communication | VME backplane interface |

| Expansion Capability | Up to 7 expander modules (120 total inputs) |

| Operating Temperature | -40°C to +85°C (-40°F to 185°F) |

| Humidity | 5% to 95% non-condensing |

| Protection Rating | IP65 (with optional enclosure) |

| Dimensions | 118 mm x 70 mm x 25 mm (4.65″ x 2.75″ x 0.98″) |

| Weight | 0.35 kg (0.77 lbs) |

| Configuration Software | GE Proficy Machine Edition / Logi.Master 90 |

Main Features and Advantages

High-Density Channel Count: The IC697ALG234 doubles the input capacity of the IC697ALG230 with 16 differential channels, reducing the number of modules required for large-scale systems. This minimizes rack space and lowers installation costs while maintaining high precision.

High-Density Channel Count: The IC697ALG234 doubles the input capacity of the IC697ALG230 with 16 differential channels, reducing the number of modules required for large-scale systems. This minimizes rack space and lowers installation costs while maintaining high precision.

Flexible Signal Conditioning: Each channel supports independent scaling for voltage or current inputs, accommodating a wide range of sensors (e.g., pressure transducers, flow meters). The oversampling technology reduces noise by averaging multiple readings, achieving 16-bit effective resolution for critical measurements.

Rugged Reliability: Built with ECC memory and dual-redundant power paths, the module ensures data integrity even in unstable power environments. Its IP65-rated enclosure and extended temperature range make it suitable for outdoor installations, high-vibration machinery, or corrosive industrial settings.

Scalable Architecture: By integrating with IC697ALG440/441 expander modules, the IC697ALG234 enables systems to grow from 16 to 120 analog inputs, providing a future-proof solution for expanding automation needs. This scalability is particularly valuable in applications like smart factories or utility grids requiring incremental upgrades.

Easy Integration: The removable terminal block and software-based configuration eliminate the need for physical jumpers, streamlining commissioning. Compatibility with GE’s Proficy Machine Edition ensures seamless integration with existing PLC programming environments.

Application Areas

The GE Fanuc IC697ALG234 excels in industries demanding high-channel analog monitoring:

The GE Fanuc IC697ALG234 excels in industries demanding high-channel analog monitoring:

- Oil and Gas: Monitors wellhead pressure, temperature, and flow rates across multiple wells, enabling real-time optimization of production processes.

- Power Generation: Tracks steam turbine performance, boiler parameters, and generator health in thermal and nuclear power plants, ensuring compliance with safety standards.

- Water/Wastewater: Manages pump efficiency, tank levels, and effluent quality in municipal treatment facilities by aggregating data from distributed sensors.

- Chemical Processing: Controls reactor conditions, pH levels, and ingredient flow rates in pharmaceutical and petrochemical production, minimizing waste and ensuring product consistency.

- Transportation Infrastructure: Monitors tunnel ventilation systems, railway signaling equipment, and bridge structural health by consolidating data from diverse analog sources.

Related Products

ABB IGCT 5SHY4045L0006 3BHB030310R0001 Module

In stock IC697ACC729 Factory Sealed Plc Programming

IC697ACC744 – GE Fanuc Emerson – PDF Supply

FANUC IC697ACC735 / IC697ACC735

IC697ACC732 Automation Control

GE-Emerson IC697ACC730 Series 90

IC697ACC728 PLC programmable controller micro expansion

FANUC IC697ACC727 / IC697ACC727 (NEW IN BOX)

IC697ACC726 Automation Control

GE Fanuc Emerson Series 90-70 – IC697ACC724

IC697ACC723 Automation Control

Installation and Maintenance

Installation Preparation: Power down the PLC system and ensure proper grounding before installing the IC697ALG234. Use ESD protection to handle the module, and connect the 5V DC power supply. Mount the module on a DIN rail or bulkhead, following the wiring diagram in the user manual. Configure channel parameters (voltage/current type, scaling) using GE’s Proficy Machine Edition, and enable expansion ports if integrating with expander modules.

Installation Preparation: Power down the PLC system and ensure proper grounding before installing the IC697ALG234. Use ESD protection to handle the module, and connect the 5V DC power supply. Mount the module on a DIN rail or bulkhead, following the wiring diagram in the user manual. Configure channel parameters (voltage/current type, scaling) using GE’s Proficy Machine Edition, and enable expansion ports if integrating with expander modules.

Maintenance Recommendations: Inspect wiring connections quarterly and clean the module with a dry, anti-static cloth. Replace the IC697ACC701 lithium battery every 5–7 years to maintain memory retention. Monitor diagnostic LEDs for power or communication faults, and recalibrate sensors annually using GE-certified tools. For systems with optional IP65 enclosures, check seal integrity biannually to prevent moisture ingress.

Product Assurance

The GE Fanuc IC697ALG234 is backed by a 1-year warranty covering defects in materials and workmanship. The module undergoes rigorous testing to meet international standards (IEC 61131-2, UL 508), ensuring long-term reliability. GE Fanuc’s global technical support team provides 24/7 assistance for troubleshooting, firmware updates, and system integration. Optional extended warranties and preventive maintenance contracts are available for customers requiring enhanced coverage.

The GE Fanuc IC697ALG234 is backed by a 1-year warranty covering defects in materials and workmanship. The module undergoes rigorous testing to meet international standards (IEC 61131-2, UL 508), ensuring long-term reliability. GE Fanuc’s global technical support team provides 24/7 assistance for troubleshooting, firmware updates, and system integration. Optional extended warranties and preventive maintenance contracts are available for customers requiring enhanced coverage.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com