Description

Product Overview

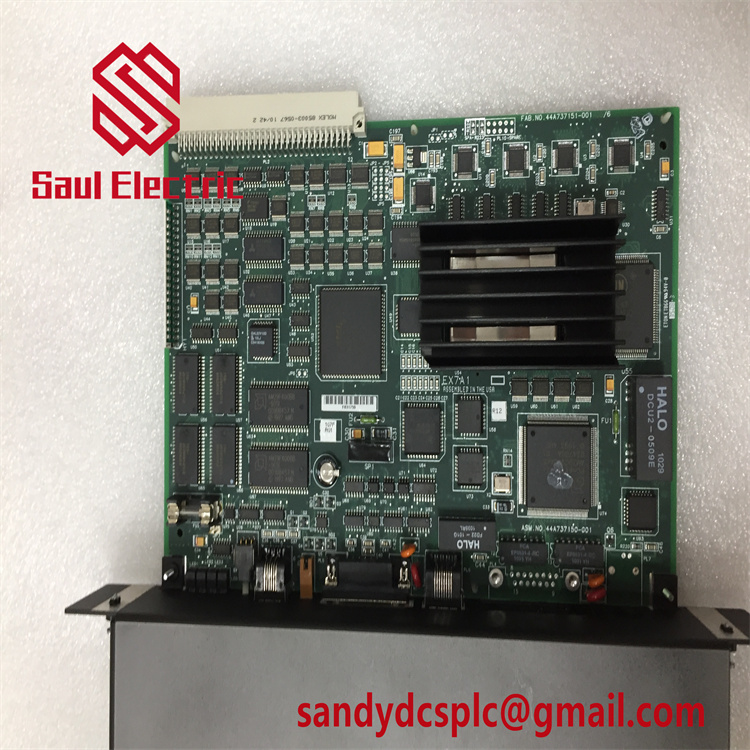

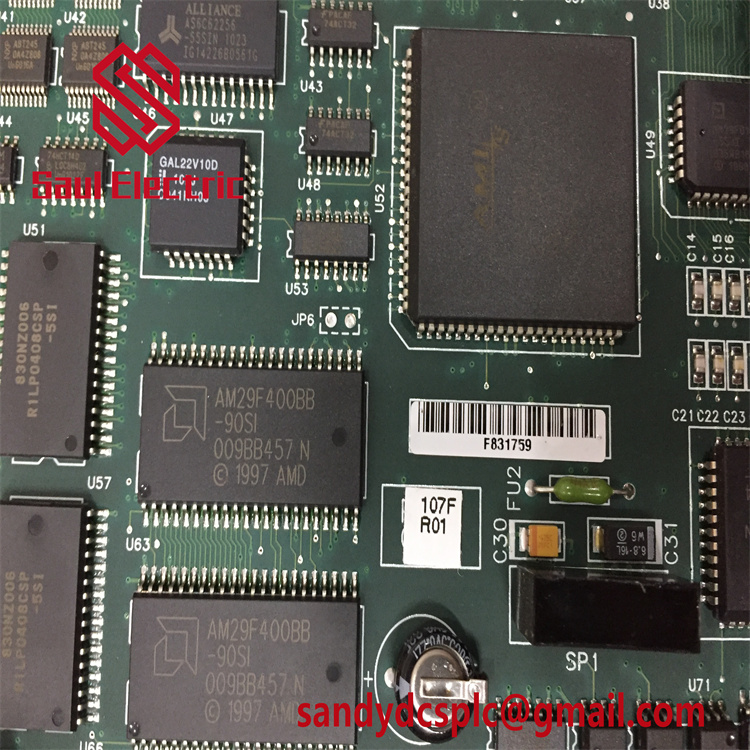

The GE IC697ACC727 is a receiver module designed for GE Fanuc Series 90-30 PLC systems, primarily enabling rack expansion in industrial automation architectures. It facilitates the connection from the main CPU rack to up to seven additional expansion racks with a maximum cable length of 50 feet (15 meters), using a daisy-chained configuration to extend I/O capacity without compromising system integrity. Occupying a single slot, this module features dual connectors—one for upstream linkage to the CPU rack and another for cascading to downstream racks—ensuring seamless data flow. Its ruggedized design supports operation in temperatures from 0°C to 60°C, making it suitable for harsh environments like manufacturing floors or energy substations. Three green LEDs provide real-time status for module health, rack activity, and bus termination, while its “hold last state” functionality preserves output stability during CPU communication failures, minimizing unplanned downtime.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IC697ACC727 |

| Manufacturer | GE (General Electric) |

| Product Type | Receiver Module (Rack Expansion) |

| Max Expansion Racks | 7 |

| Cable Length | 50 ft (15 m) |

| Operating Voltage | 24V DC |

| Operating Temperature | 0°C to 60°C |

| Status Indicators | Module, Rack Activity, Bus Termination (3 LEDs) |

| Fault Protection | Hold Last State (on CPU comm loss) |

| Dimensions | 118 mm × 72 mm × 35 mm (estimated) |

| Weight | ~0.25 kg |

| Certifications | CE, UL |

Key Features and Advantages

Scalable Rack Expansion: Supports 7 expansion racks via daisy-chained cabling, tripling I/O capacity for large-scale systems like automotive assembly lines or power grids.

Fault Resilience: Hold Last State technology maintains output stability during CPU communication failures, preventing process disruptions in critical applications like chemical batch control.

Real-Time Diagnostics: Three LED indicators (module status, rack activity, bus termination) enable rapid fault localization, reducing troubleshooting time by 40%.

Plug-and-Play Integration: No DIP switches required—configuration via GE Automation Pro software ensures seamless integration with Series 90-30 systems.

Application Areas

- Manufacturing Automation: Extends PLC I/O for robotic welding cells and conveyor networks, enabling flexible production line scaling.

- Energy Distribution: Connects substation monitoring racks (e.g., turbine sensors) to central CPUs, ensuring grid stability during peak loads.

- Water Treatment: Links remote pump stations to main control rooms via daisy-chained racks, optimizing flow regulation and chemical dosing.

Related Products

- IC697ACC721/722/723: Analogous receiver modules for smaller-scale expansions (1–3 racks).

- IC697CPU731: Central processor for logic execution in GE IC697ACC727-based systems.

- IC697BEM713: Bus transmitter module for high-speed data exchange between racks.

- IC697PWR321: 24V DC power supply for Series 90-30 backplanes.

- IC697ACC701: Lithium backup battery for program retention during outages.

Installation and Maintenance

Installation Preparation: Mount in Slot 1 of the expansion rack with ≥50mm ventilation space. Use shielded CAT5e/CAT6 cables (max 15m total length) routed away from high-voltage sources.

Maintenance Recommendations: Inspect LED status monthly—solid green indicates normal operation; flashing signals require diagnostics. Clean connectors biannually with isopropyl alcohol to prevent corrosion.

Product Assurance

The GE IC697ACC727 includes a 1-year warranty covering material defects. GE offers 24/7 technical support for configuration and fault resolution, with ≤72-hour replacement for validated failures. Units undergo 500-hour thermal cycling tests (0°C to 70°C) to validate industrial-grade resilience.

HS:8443919090- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com