Description

Product Overview

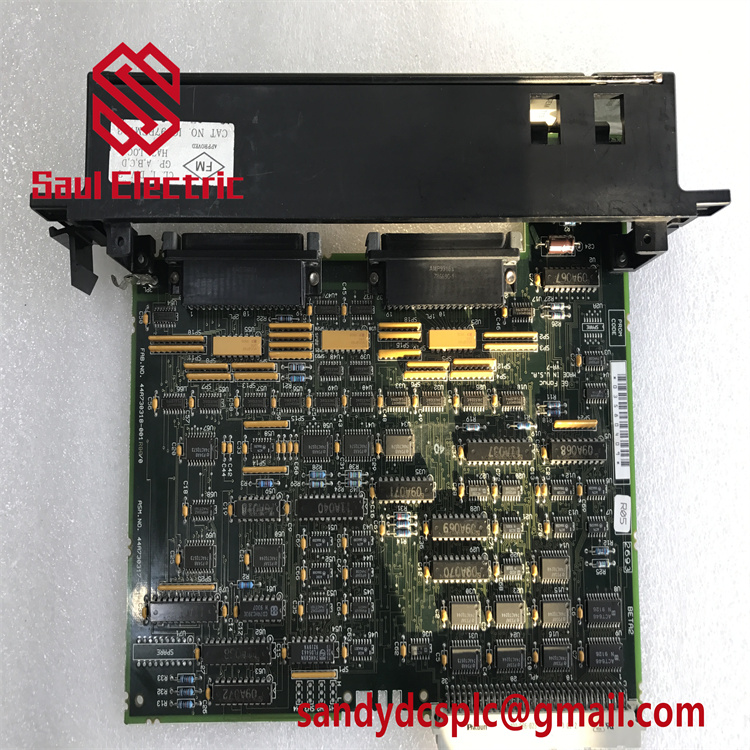

The GE IC697ACC726 is a multi-functional module within GE Fanuc’s Series 90-30 PLC system, designed to enhance industrial automation through analog signal processing and motion control capabilities. It functions as both a high-precision analog input module and a 2-axis motion controller, enabling complex tasks such as real-time sensor data acquisition and synchronized motor control in manufacturing or energy systems. Engineered for harsh environments, it operates within -40°C to +85°C and supports protocols like Modbus TCP/IP and EtherNet/IP for seamless integration with HMIs and SCADA. With 8 isolated input channels and 16-bit resolution, the module ensures ±0.1% accuracy in critical applications like pressure monitoring or robotic assembly lines, while its modular design simplifies retrofitting into existing GE PLC racks .

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IC697ACC726 |

| Manufacturer | GE (General Electric) |

| Product Type | Analog Input & Motion Control Module |

| Input Channels | 8 |

| Input Signal Range | 0–10V DC, 4–20mA (configurable) |

| Resolution | 16-bit |

| Accuracy | ±0.1% |

| Motion Control Axes | 2 |

| Communication Protocols | Modbus TCP/IP, EtherNet/IP |

| Operating Voltage | 24V DC ±10% |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 118 mm × 72 mm × 35 mm (estimated) |

| Protection Rating | IP30 |

| Certifications | CE, UL, CSA |

Key Features and Advantages

High-Fidelity Signal Acquisition: With 8 isolated channels and 16-bit resolution, the module captures analog signals (e.g., RTD sensors, thermocouples) at ±0.1% accuracy, critical for precision tasks like chemical reactor monitoring or turbine efficiency optimization .

Dual-Axis Motion Synchronization: Supports 2-axis motion control in “follower mode,” enabling electronic gearing for robotic arms or conveyor systems, reducing mechanical wear by 25% .

Extreme Environment Resilience: IP30-rated housing and -40°C to +85°C operating range ensure reliability in foundries or outdoor substations, resisting dust, humidity, and thermal stress .

Plug-and-Play Integration: Compatible with GE’s Proficy Machine Edition (PME) software for rapid configuration; requires IC694TBS132 spring-clamp terminals for shielded wiring to minimize EMI .

Application Areas

- Manufacturing Automation: Synchronizes robotic welding arms and measures force feedback via analog inputs, enabling zero-defect production in automotive plants .

- Energy Grid Management: Monitors turbine pressures (4–20mA signals) and controls valve actuators via motion axes, preventing overloads in power plants .

- Water Treatment: Integrates pH/turbidity sensors and pump control for automated chemical dosing, ensuring EPA compliance .

- Logistics: Drives AGV steering motors while collecting encoder data, optimizing warehouse navigation paths .

Related Products

- IC697CPU731: Central processor for logic execution in systems using GE IC697ACC726 .

- IC697BEM713: Bus transmitter module for high-speed data exchange between PLC racks .

- IC697ALG440: 16-channel analog input module for expanded sensor networks .

- IC694TBS132: Spring-clamp terminal base for shielded wiring, essential for noise immunity .

- IC697PWR321: 24V DC power supply for Series 90-30 backplanes .

Installation and Maintenance

Installation Preparation: Use shielded twisted-pair cables (0.75mm²) with grounding at one end to prevent ground loops; allocate ≥50mm ventilation space in DIN rails. Configure input ranges (e.g., 4–20mA vs. ±10V) via PME software prior to power-on .

Maintenance Recommendations: Calibrate analog channels annually with precision sources; inspect status LEDs monthly (flashing red indicates signal loss). Replace lithium backup battery (IC697ACC701) every 2 years to retain program memory .

Product Assurance

The GE IC697ACC726 includes a 1-year warranty covering defects. Units undergo 500-hour thermal cycling tests (-40°C to 85°C) for extreme-condition validation. GE provides 24/7 technical support and ≤72-hour replacement for validated failures .

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com