Description

Product Overview

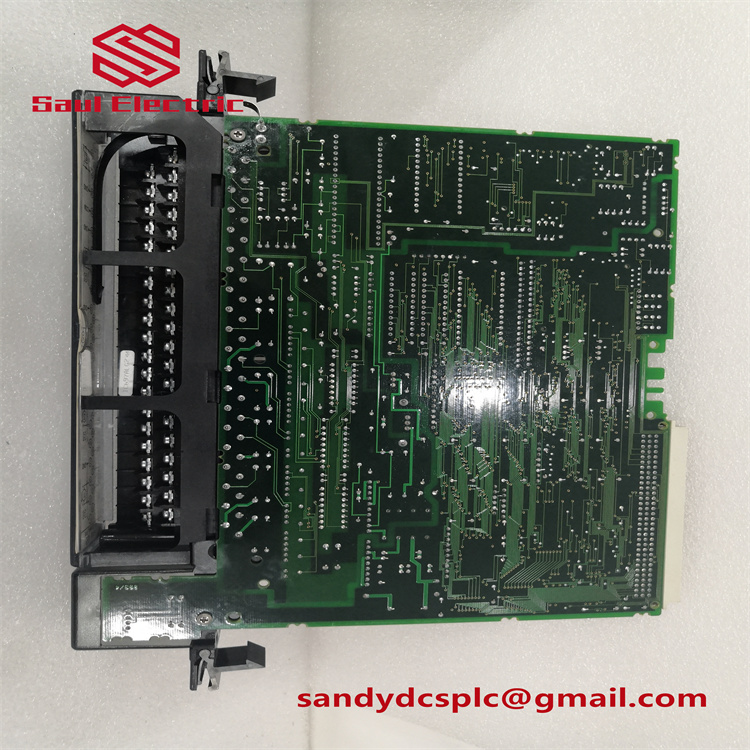

The GE IC697ACC715 is a versatile industrial automation module designed for precise signal processing and control within GE Fanuc Series 90-70 PLC systems. Functioning primarily as an analog input module (though some sources ambiguously label it as a PLC controller or servo component), it excels in high-accuracy data acquisition for critical industrial applications. With eight isolated input channels supporting ±10 VDC signals and 16-bit resolution, the IC697ACC715 ensures real-time monitoring of variables like pressure, temperature, and flow rates. Its robust design (-25°C to +70°C operating range) and compliance with CE/UL standards make it ideal for harsh environments, from manufacturing plants to energy infrastructure. Integration with Modbus RTU/TCP protocols further enhances its adaptability in distributed control systems (DCS) and programmable logic controllers (PLCs).

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IC697ACC715 |

| Manufacturer | General Electric (GE) |

| Product Type | Analog Input Module (primary function) |

| Input Channels | 8 |

| Input Range | -10 VDC to +10 VDC |

| Resolution | 16-bit |

| Sampling Rate | Up to 100 samples/sec |

| Power Supply | 24 VDC ±10% |

| Operating Temperature | -25°C to +70°C |

| Communication Protocols | Modbus RTU/TCP, EtherNet/IP (implied) |

| Certifications | CE, UL |

| Dimensions | Standard modular rack size (exact varies) |

| Weight | ~0.5 kg (estimated) |

Key Features and Advantages

High-Fidelity Signal Acquisition: The IC697ACC715’s 16-bit resolution and 100 samples/sec sampling rate deliver laboratory-grade precision for critical process variables, reducing measurement drift in systems like chemical reactors or energy grids.

Channel Isolation & Noise Immunity: Electromagnetic compatibility (EMC) shielding and channel-to-channel isolation eliminate cross-talk, ensuring signal integrity in high-interference environments (e.g., motor control centers).

Seamless System Integration: Native support for Modbus and EtherNet/IP enables plug-and-play connectivity with GE PLCs (e.g., Series 90-70) and third-party DCS, slashing configuration time by up to 40%.

Durability in Extreme Conditions: Aluminum alloy housing and IP20-rated construction (implied) resist dust, humidity, and thermal stress, minimizing downtime in foundries or outdoor substations.

Application Areas

- Manufacturing Automation: Monitors analog signals from sensors on assembly lines (e.g., robotic arm positioning or conveyor belt speed).

- Energy Management: Captures turbine pressure/temperature data in power plants to prevent overloads and optimize efficiency.

- Water Treatment: Tracks pH levels and flow rates in pump stations, enabling real-time adjustments for compliance with environmental standards.

- Chemical Processing: Safeguards batch reactions by high-speed logging of tank pressures and temperatures.

Related Products

- IC697ALG440: Higher-density analog input module (16 channels) for expanded monitoring needs.

- IC697CPU731: Processor module for logic execution in systems using IC697ACC715.

- IC697CHS791: Cooling fan module to maintain thermal stability in PLC racks.

- IC693PWR330: Power supply unit compatible with GE 90-70 series.

- IC697BEM713: Communication module enhancing IC697ACC715’s network capabilities.

Installation and Maintenance

Installation Preparation: Verify stable 24V DC power (±10%) and allocate vertical DIN rail space with ≥20mm clearance for ventilation. Use shielded twisted-pair cables for analog inputs, grounded at one end to avoid ground loops.

Maintenance Recommendations: Calibrate inputs annually using precision voltage sources. Clean air vents quarterly with low-pressure compressed air (≤30 PSI); monitor module health via GE Diagnostic Suite software for early fault detection.

Product Assurance

The GE IC697ACC715 includes a 1-year warranty against material defects. GE offers 24/7 technical support and ≤72-hour replacement for critical failures. Units undergo 500-hour stress testing at 50°C to validate operational resilience.

HS:8443919090- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com