Description

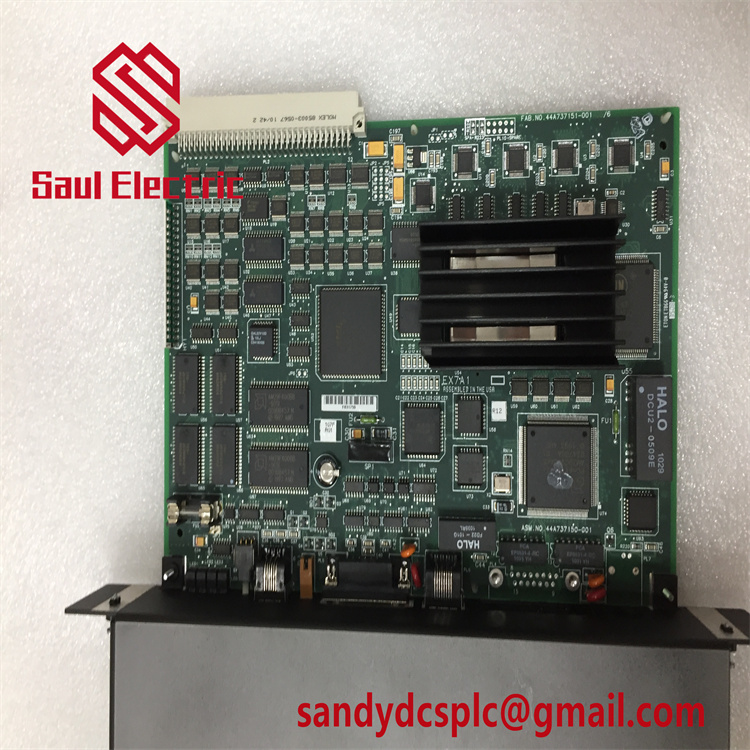

Product Overview

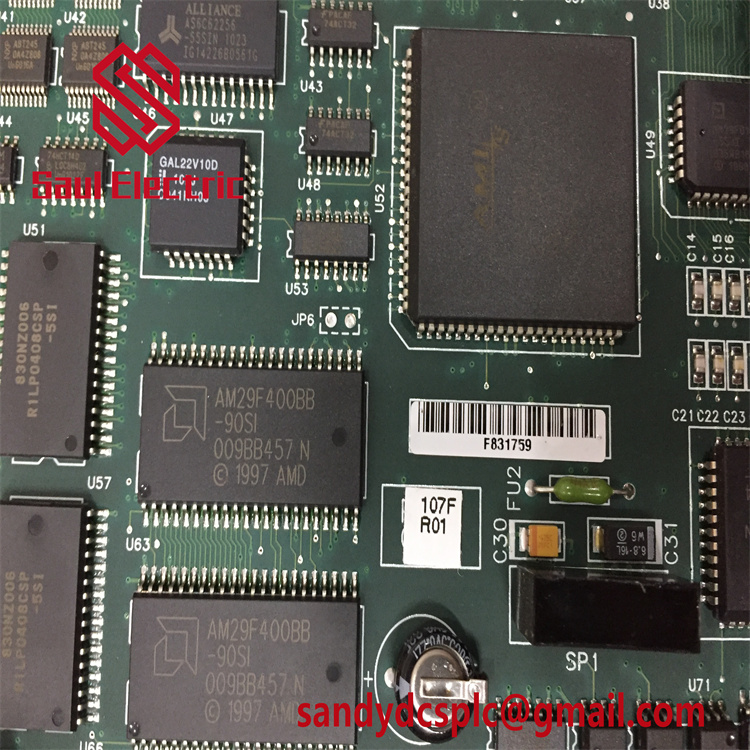

The GE IC697ACC624 is a rack-mounted fan assembly engineered for critical thermal management in industrial automation systems, particularly within GE Fanuc Series 90-70 PLC racks. Designed to dissipate heat from densely packed control modules, this component ensures system stability by preventing overheating in high-demand environments. Its aluminum construction optimizes heat transfer while maintaining structural integrity under vibration and thermal stress. Operating at 120V AC with variable speed control (0–3,400 RPM), the IC697ACC624 dynamically adjusts cooling intensity based on real-time temperature feedback. This adaptability minimizes energy consumption while safeguarding sensitive electronics like processors and I/O modules. With certifications including UL, CE, and FCC, it meets stringent industrial safety standards, making it indispensable for manufacturing plants, power facilities, and process industries where uninterrupted operation is non-negotiable.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IC697ACC624 |

| Manufacturer | GE (General Electric) |

| Product Type | Rack Fan Assembly |

| Operating Voltage | 120V AC ±10% |

| Current Consumption | Max 0.3A |

| Speed Range | 0–3,400 RPM (variable) |

| Airflow Capacity | 36 CFM |

| Noise Level | 32 dBA (max 42 dBA) |

| Dimensions (W×D×H) | 105 mm × 120 mm × 105 mm |

| Weight | ~0.5 kg (estimated) |

| Operating Temperature | -10°C to +50°C |

| Humidity Tolerance | 0–95% RH (non-condensing) |

| Material | Aluminum alloy |

| Certifications | UL, CE, FCC |

Key Features and Advantages

Intelligent Thermal Management: The IC697ACC624 employs PWM-based speed modulation, automatically increasing airflow during peak loads (e.g., processor-intensive tasks) and reducing power during idle periods. This cuts energy use by up to 40% compared to fixed-speed fans.

Robust Environmental Resilience: Engineered for harsh settings, its aluminum housing resists corrosion from dust, chemicals, or humidity. The IP20-rated design prevents particulate ingress, while a -10°C to +50°C operating range ensures reliability in foundries or outdoor installations.

Low-Noise Operation: At ≤32 dBA under typical loads, the fan minimizes acoustic disruption in control rooms—critical for facilities with strict noise regulations. Vibration-damping mounts further reduce mechanical resonance.

Easy Integration & Maintenance: Tool-less DIN rail mounting simplifies installation in GE 90-70 racks. Front-facing status LEDs alert technicians to airflow degradation, enabling proactive maintenance before overheating occurs.

Application Areas

- Manufacturing Automation: Cools PLC cabinets in automotive assembly lines, preventing shutdowns due to CPU overheating during continuous 24/7 operations.

- Energy Infrastructure: Deployed in power plant DCS cabinets to dissipate heat from high-wattage modules (e.g., drives or redundant power supplies), ensuring grid stability.

- Chemical Processing: Maintains optimal temperatures in corrosive environments where volatile compounds demand explosion-resistant cooling solutions.

- Water Treatment Facilities: Extends equipment lifespan in humid pump-control stations by mitigating moisture-induced component stress.

Related Products

- IC697CHS791: Complementary cooling fan module for GE 90-70 racks, offering higher airflow (45 CFM) for larger enclosures.

- IC697ACC724: Analog input module often paired with IC697ACC624; requires active cooling for precision signal integrity.

- IC697PWR711: Power supply unit benefiting from the IC697ACC624’s thermal management to prevent voltage drift.

- IC697CPU731: Processor module that generates significant heat; relies on IC697ACC624 for sustained performance.

- IC697CBL700: Fan cabling kit for simplified wiring integration.

Installation and Maintenance

Installation Preparation: Verify 120V AC power stability (±10%) and allocate vertical DIN rail space. Ensure 50mm clearance around vents for unobstructed airflow. Use shielded cables routed away from high-voltage lines to reduce EMI.

Maintenance Recommendations: Clean dust filters quarterly using compressed air (≤30 PSI). Monitor airflow via GE Diagnostic Suite software; replace if RPM drops >15% below baseline. Lubricate bearings annually with NSF-H1 grease for high-humidity sites.

Product Assurance

The GE IC697ACC624 includes a 1-year warranty covering material defects. GE provides 24/7 technical support and ≤72-hour replacement for critical failures. Each unit undergoes 500-hour endurance testing at 50°C to validate thermal resilience.

HS:8443919090- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com