Description

Product Overview

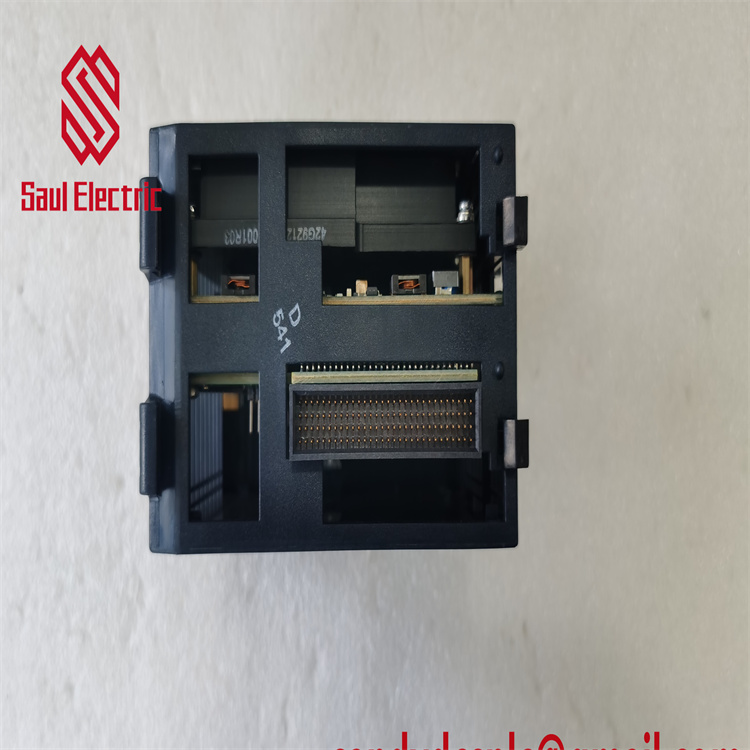

The GE IC695MGMT1YR is a specialized Maintenance Management Kit designed for GE PACSystems RX3i industrial automation platforms. Engineered to streamline system upkeep and reduce downtime, this kit integrates hardware and software tools to support proactive maintenance strategies. As part of the PACSystems RX3i series, it enhances the reliability of critical industrial systems by providing real-time diagnostics, firmware updates, and remote monitoring capabilities .

The IC695MGMT1YR includes a dedicated management module and a 1-year subscription to GE’s Proficy Maintenance software, enabling centralized control over system health. It interfaces seamlessly with PACSystems controllers like the IC695CRU320 and IC695PMM335, allowing users to schedule maintenance tasks, track component lifecycle data, and analyze equipment performance trends. This solution is ideal for industries such as power generation, oil and gas, and manufacturing, where continuous operation is essential .

With its rugged design (IP65 ingress protection) and wide operating temperature range (-40°C to +85°C), the IC695MGMT1YR ensures consistent performance in harsh environments. It complies with industry standards like IEC 61131-2 and offers redundant communication paths for fault-tolerant systems. By combining hardware resilience with advanced software analytics, this kit empowers organizations to optimize maintenance costs while extending equipment lifespan.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IC695MGMT1YR |

| Manufacturer | GE Fanuc |

| Product Type | (Hardware + Software Subscription) |

| Communication Protocol | PROFINET, EtherNet/IP, Modbus TCP |

| Interface Type | Ethernet (RJ45), Serial (RS-232/485) |

| Physical Dimensions | 170mm × 90mm × 70mm (H×W×D) |

| Weight | 0.8 kg |

| Operating Temperature | -40°C to +85°C |

| Power Supply | 19.2–28.8 VDC |

| Software Included | Proficy Maintenance (1-year license) |

| Redundancy Support | Dual Ethernet links for fault-tolerant communication |

| Data Storage | 8GB flash memory for diagnostic logs |

| Certifications | CE, UL 508 |

Key Features and Advantages

Integrated Hardware-Software Solution:

The IC695MGMT1YR combines a compact management module with Proficy Maintenance software, enabling end-to-end maintenance lifecycle management. Users can schedule predictive maintenance tasks, monitor asset health in real time, and generate actionable reports for informed decision-making .

The IC695MGMT1YR combines a compact management module with Proficy Maintenance software, enabling end-to-end maintenance lifecycle management. Users can schedule predictive maintenance tasks, monitor asset health in real time, and generate actionable reports for informed decision-making .

Remote Monitoring and Diagnostics:

Equipped with dual Ethernet ports, the module supports remote access to system logs, firmware updates, and configuration settings. This reduces the need for on-site visits, particularly valuable for distributed industrial facilities .

Equipped with dual Ethernet ports, the module supports remote access to system logs, firmware updates, and configuration settings. This reduces the need for on-site visits, particularly valuable for distributed industrial facilities .

Proactive Health Analytics:

The included software analyzes historical data to predict component failures, such as vibration anomalies in rotating equipment or voltage fluctuations in power systems. This feature helps reduce unplanned downtime by up to 30% .

The included software analyzes historical data to predict component failures, such as vibration anomalies in rotating equipment or voltage fluctuations in power systems. This feature helps reduce unplanned downtime by up to 30% .

Rugged Industrial Design:

Built to withstand extreme temperatures and EMI interference, the IC695MGMT1YR meets IP65 standards for dust and water resistance. Its compact form factor minimizes rack space while maintaining high-performance capabilities .

Built to withstand extreme temperatures and EMI interference, the IC695MGMT1YR meets IP65 standards for dust and water resistance. Its compact form factor minimizes rack space while maintaining high-performance capabilities .

Seamless Integration:

Compatible with PACSystems RX3i controllers and third-party systems, the kit simplifies integration into existing automation architectures. It supports hot-swappable module replacement, ensuring minimal disruption during maintenance .

Compatible with PACSystems RX3i controllers and third-party systems, the kit simplifies integration into existing automation architectures. It supports hot-swappable module replacement, ensuring minimal disruption during maintenance .

Application Areas

The GE IC695MGMT1YR is tailored for industries requiring systematic maintenance strategies:

- Power Generation: Monitoring steam turbines and generators to prevent unexpected failures, aligning with API 670 standards for machinery health .

- Oil and Gas: Managing offshore platforms’ critical assets, including compressors and wellhead equipment, through real-time diagnostics .

- Manufacturing: Optimizing CNC machine performance by tracking torque and vibration data, reducing wear and tear on precision tools .

- Mining: Protecting conveyor systems and crushers through predictive maintenance, extending component lifespan in harsh environments .

By centralizing maintenance workflows, the IC695MGMT1YR helps organizations achieve compliance, reduce operational costs, and enhance overall equipment effectiveness (OEE).

Related Products

- IC695CRU320: Redundant CPU module for high-availability systems, ensuring uninterrupted operation during maintenance cycles .

- IC695ETM001: High-performance Ethernet module for plant-level connectivity, enabling remote access to the maintenance kit .

- IC695PMM335: PACMotion Multi-Axis Motion Controller, which can be monitored for vibration and position accuracy via the IC695MGMT1YR .

- IC695ALG230: Analog input module for temperature and pressure monitoring, providing critical data for maintenance analytics .

- IC695MDL664: Digital I/O module for general-purpose monitoring, complementing the kit’s diagnostic capabilities .

- IC695HSC304: High-speed counter module for precise motion control, supporting predictive maintenance of machinery dynamics .

- IC695LRE001: Serial bus transmitter module for remote 背板扩展,extending the kit’s reach in large-scale industrial setups .

These modules work synergistically with the IC695MGMT1YR to form a comprehensive maintenance ecosystem.

Installation and Maintenance

Installation Preparation:

Before installing the IC695MGMT1YR, ensure the PACSystems RX3i rack is powered off and grounded. Align the module with the rack’s slot guides and secure it using the retention bracket. Connect Ethernet and serial cables to the respective ports, then install the Proficy Maintenance software on a dedicated PC or server. Configure network settings to enable communication between the module and the software .

Before installing the IC695MGMT1YR, ensure the PACSystems RX3i rack is powered off and grounded. Align the module with the rack’s slot guides and secure it using the retention bracket. Connect Ethernet and serial cables to the respective ports, then install the Proficy Maintenance software on a dedicated PC or server. Configure network settings to enable communication between the module and the software .

Maintenance Recommendations:

Regularly review diagnostic logs stored in the module’s flash memory to identify potential issues. Update firmware quarterly to access the latest features and security patches. Clean the module’s exterior with a dry cloth to prevent dust accumulation, and inspect cable connections for looseness. For software-related issues, leverage GE’s 24/7 technical support to resolve configuration or licensing challenges .

Regularly review diagnostic logs stored in the module’s flash memory to identify potential issues. Update firmware quarterly to access the latest features and security patches. Clean the module’s exterior with a dry cloth to prevent dust accumulation, and inspect cable connections for looseness. For software-related issues, leverage GE’s 24/7 technical support to resolve configuration or licensing challenges .

Product Assurance

The GE IC695MGMT1YR is backed by a 1-year warranty covering hardware defects and software license validity. GE’s global support network provides 24/7 technical assistance, including remote diagnostics and firmware updates. All hardware undergoes rigorous testing to meet ISO 9001 quality standards, ensuring long-term reliability in demanding industrial environments. For mission-critical applications, extended warranties and priority support plans are available. Trust the IC695MGMT1YR to deliver unmatched performance and peace of mind in maintenance management .

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com