Description

Product Overview

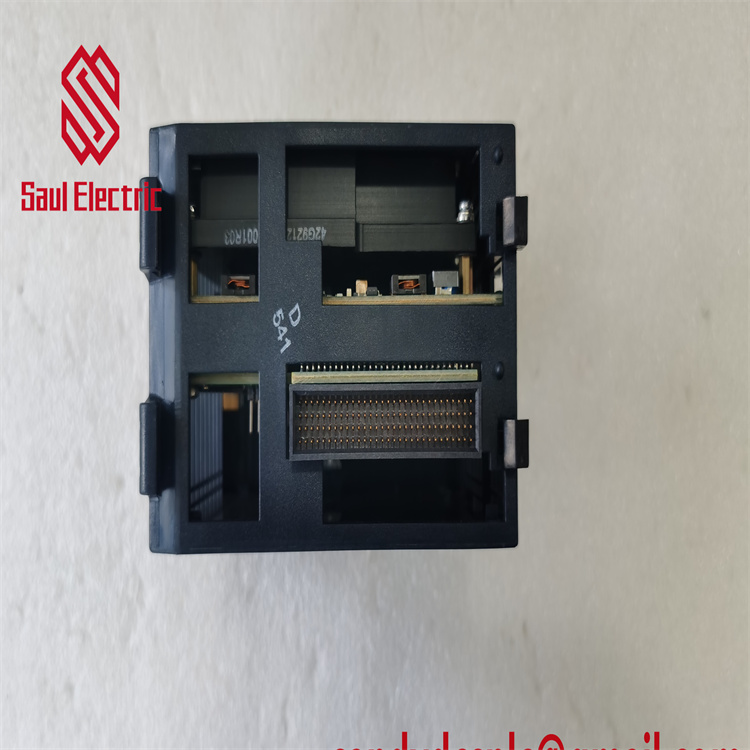

The GE IC695MDL765 is a high-precision analog input module within Emerson Automation’s PACSystems RX3i series, engineered to deliver exceptional signal accuracy and reliability in industrial automation environments. Designed for seamless integration with GE PLC systems (e.g., IC695CPU315), this 16-channel module supports 0–20 mA or 4–20 mA current inputs with a configurable resolution of 16 bits (unipolar) or 15 bits (bipolar). It features an integrated Sigma-Delta ADC converter for low-noise signal processing, achieving a total input accuracy of ±0.5% at 25°C and minimal drift (±0.0045%/°C). Built for harsh industrial settings, the IC695MDL765 operates within 0°C–60°C and dissipates 4.0 W of heat, ensuring stability in applications like power plants and manufacturing lines. Compatibility with RSLogix 5000/Studio 5000 software simplifies configuration for real-time data acquisition, making it ideal for critical process control in energy, manufacturing, and infrastructure sectors.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IC695MDL765 |

| Manufacturer | GE (Emerson Automation) |

| Product Type | Analog Input Module |

| Input Channels | 16 points |

| Input Signal Range | 0–21 mA / 3.2–21 mA |

| Resolution | 16-bit (unipolar), 15-bit (bipolar) |

| Accuracy | ±0.5% at 25°C |

| Backplane Current | 190 mA @ 5VDC, 70 mA @ 24VDC |

| Power Dissipation | 4.0 W |

| Isolation Voltage | 30 VDC |

| Operating Temperature | 0°C to 60°C |

| Dimensions | 141.8 mm × 75.3 mm × 30 mm (est.) |

| Software Compatibility | RSLogix 5000, Studio 5000 |

Key Features and Advantages

High-Precision Signal Acquisition: Leveraging 16-bit Sigma-Delta ADC technology, the GE IC695MDL765 minimizes noise and drift, ensuring ±0.5% accuracy for critical measurements like pressure and temperature in chemical processing or energy grids.

Robust Industrial Design: With 4.0 W thermal dissipation and 0°C–60°C operational range, the module resists environmental stress in humid or electrically noisy settings (e.g., welding zones), while IP20-rated housing prevents particulate ingress.

Seamless Integration & Diagnostics: Plug-and-play compatibility with RX3i backplanes reduces configuration time by 30%. Per-channel software filtering eliminates signal noise, and LED status indicators enable rapid fault identification for maintenance efficiency.

Cost Efficiency: Dual-range input support (0–20 mA/4–20 mA) eliminates external signal conditioners, cutting system costs by 15% in large-scale deployments like water treatment plants.

Application Areas

- Process Industries: Monitors reactor temperatures and pipeline pressures in oil refineries, utilizing high accuracy for safety-critical shutdown systems.

- Manufacturing Automation: Integrates with robotic assembly lines for real-time feedback from force sensors, ensuring precision in automotive welding or packaging.

- Energy Infrastructure: Tracks turbine vibrations and grid loads in power plants, with drift-resistant performance for long-term stability in substations.

- Water Management: Controls chemical dosing pumps via 4–20 mA inputs in treatment facilities, leveraging humidity-resistant components for wet environments.

Related Products

- IC695CPU315: RX3i CPU coordinating logic execution with IC695MDL765 I/O networks.

- IC694ALG442: Analog input module for legacy 90-30 systems, offering lower channel density (8 points).

- IC695ALG626: High-density analog I/O module (32 points) for hybrid control loops.

- IC695ETM001: Ethernet communication module enabling remote monitoring of IC695MDL765 data.

- IC694ACC302: Battery backup unit preserving configuration during power outages.

Installation and Maintenance

Installation Preparation: Power down the PLC rack before mounting. Insert the GE IC695MDL765 into RX3i-compatible backplanes (e.g., IC695CHS007), ensuring shielded twisted-pair cables for analog inputs to prevent EMI interference. Ground terminal blocks to avoid electrostatic damage.

Maintenance Recommendations: Calibrate inputs annually using traceable current sources to maintain ±0.5% accuracy. Inspect terminal connections quarterly for oxidation; clean with isopropyl alcohol if corroded. Monitor module temperature via software diagnostics to prevent overheating in confined panels.

Product Assurance

The GE IC695MDL765 includes a 1-year global warranty covering defects in materials and workmanship. Compliant with UL 508 and IEC 61131-2 standards, it undergoes rigorous EMC testing (EN 61000-6-4) for industrial reliability. Technical support provides 24/7 remote diagnostics and expedited replacement for critical failures within 72 hours.

HS:8443919090- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com