Description

Product Overview

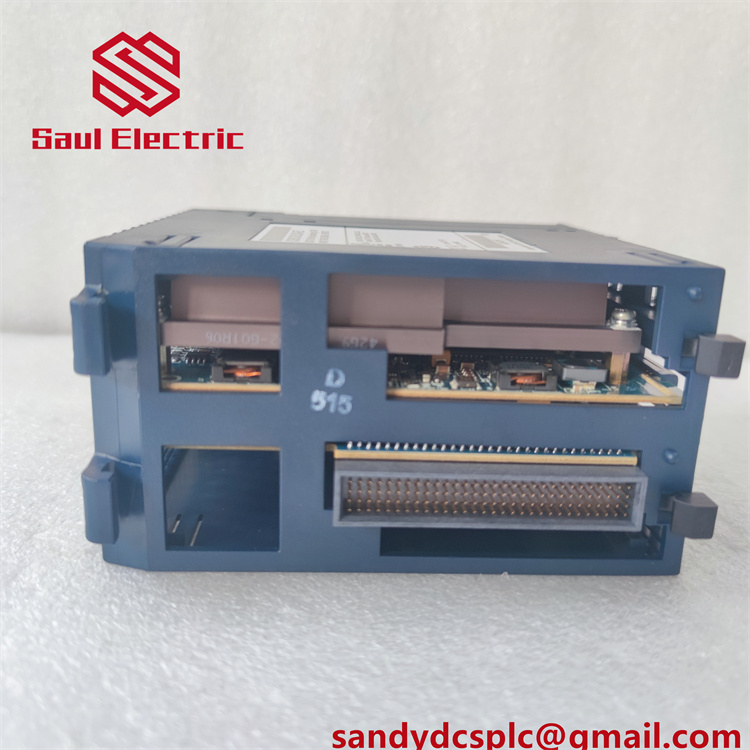

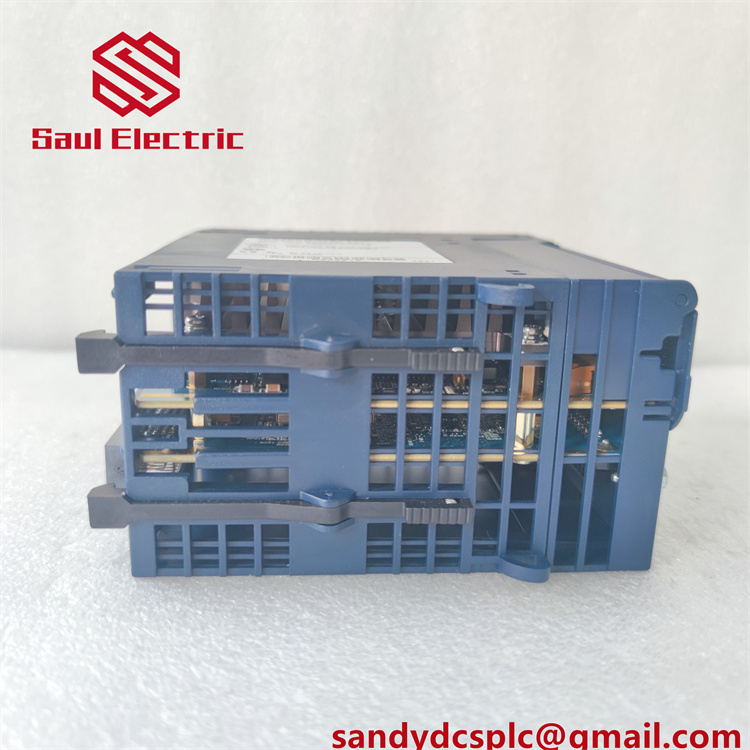

The GE IC695LCO004 is a high-density discrete output module within GE’s PACSystems RX3i platform (now under Emerson Automation), designed for robust industrial control applications. This module provides 16 isolated output channels, configurable as relay or transistor types, supporting voltage ranges from 5–30 VDC or 120/240 VAC to drive actuators, valves, indicators, and other field devices. As part of the RX3i series, the IC695LCO004 integrates seamlessly into PLC or DCS architectures, enabling precise on/off control in real-time industrial processes. Its dual-output flexibility allows users to switch between relay (for mixed AC/DC loads) and transistor (for high-speed switching) modes via firmware, eliminating hardware replacements during system reconfiguration. With channel-to-backplane isolation (1,500 VAC) and built-in protection against overcurrent/short circuits, the GE IC695LCO004 ensures operational stability in electrically noisy environments like manufacturing floors or energy plants, extending system longevity while optimizing control cabinet space.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GE IC695LCO004 |

| Manufacturer | GE (Emerson Automation) |

| Product Type | Discrete Output Module |

| Output Points | 16 channels |

| Output Type | Relay or Transistor (configurable) |

| Voltage Range | 5–30 VDC or 120/240 VAC (selectable) |

| Max Load Current | 2 A per channel (resistive) |

| Isolation | 1,500 VAC (channel-to-backplane) |

| Response Time | ≤10 ms (transistor), ≤15 ms (relay) |

| Backplane Current | 80 mA @ 5VDC |

| Operating Temperature | 0°C to 60°C |

| Protection Rating | IP20 |

| Dimensions | 118 mm × 72 mm × 35 mm (standard RX3i) |

Key Features and Advantages

Flexible Output Configuration: The GE IC695LCO004 supports both relay and transistor outputs via software configuration. Relay outputs handle mixed AC/DC loads (e.g., solenoids, motors), while transistor outputs enable high-speed switching (≤10 ms) for rapid control tasks like conveyor synchronization.

Robust Signal Integrity: With 1,500 VAC channel-to-backplane isolation and EMI-resistant design, the module prevents ground loops in harsh environments (e.g., welding facilities). Integrated diagnostics monitor open-load faults and output status, reducing troubleshooting time by 40%.

Industrial Durability: Rated for 0°C–60°C operation and vibration resistance (5g @ 10–500 Hz), the IC695LCO004 withstands mechanical stress in automotive assembly lines or offshore platforms. Hot-swap capability (with external power disconnect) minimizes downtime during maintenance.

Seamless Integration: Native compatibility with RX3i CPUs (e.g., IC695CPU315) and PAC Machine Edition software simplifies programming. Dual voltage ranges (DC/AC) accommodate global electrical standards without hardware changes.

Application Areas

- Manufacturing Automation: Controls pneumatic valves, robotic arms, and conveyor motors in automotive assembly lines, leveraging fail-safe states to prevent production halts during faults.

- Energy Infrastructure: Manages pump startups/shutdowns and cooling valve operations in power plants, with surge protection for inductive loads (e.g., turbine control solenoids).

- Water Treatment Systems: Drives chemical dosing pumps and sludge press actuators in high-humidity environments, utilizing moisture-resistant components for reliable 24/7 operation.

- Packaging Machinery: Coordinates fillers and sealers with millisecond response times, ensuring precise throughput in food/pharmaceutical production.

Related Products

- IC695MDL664: 32-point digital input module for complementary I/O monitoring in RX3i systems.

- IC695ALG626: Analog I/O module (voltage/current) for hybrid signal processing in process control.

- IC695CPU315: RX3i CPU controller for central logic coordination with IC695LCO004.

- IC694RTB032: Legacy I/O termination module for backward-compatible system upgrades.

- IC695PSD040: 40W power supply supporting rack redundancy configurations.

Installation and Maintenance

Installation Preparation: Mount vertically in RX3i racks with ≥50 mm clearance for heat dissipation. Use shielded cables for output lines exceeding 10 meters to suppress EMI. Ensure load currents ≤2A per channel to prevent overheating.

Maintenance Recommendations: Clean ventilation slots quarterly with compressed air. For relay versions, test contact resistance after 100,000 cycles; replace if >0.5 Ω. Update firmware via SD card during planned outages to optimize transient response.

Product Assurance

The GE IC695LCO004 includes a 1-year global warranty covering material and workmanship defects. Technical support provides 24/7 remote diagnostics and 72-hour on-site replacement for critical failures. Compliant with IEC 61131-2 and UL 508 safety standards, the module undergoes rigorous environmental testing (-40°C to 85°C storage) to ensure reliability in industrial deployments.

HS:8443919090- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com