Description

Many products are not yet available—feel free to contact us for more options.

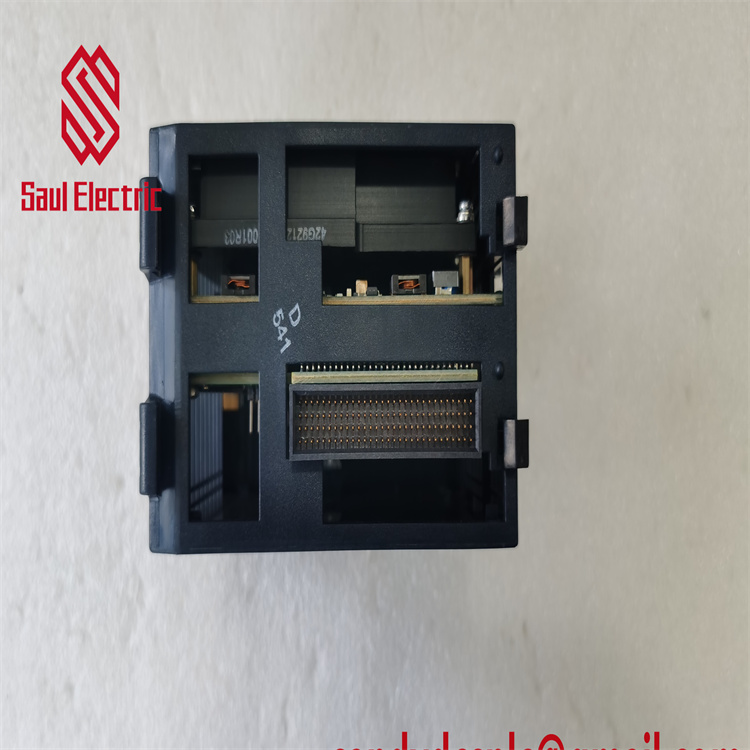

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Product Overview

The GE IC695CRH004 is a high-performance central processing unit (CPU) module designed for the PACSystems RX7i platform, engineered to deliver reliable control and automation in industrial environments. As a critical component of GE’s Series 90-30/70 PLC architecture, the IC695CRH004 integrates advanced processing capabilities with flexible communication protocols, making it ideal for complex manufacturing, energy, and process control applications. Its dual-core processor and 64 MB of user memory enable real-time data handling and seamless integration with I/O modules, HMIs, and supervisory systems.

The GE IC695CRH004 is a high-performance central processing unit (CPU) module designed for the PACSystems RX7i platform, engineered to deliver reliable control and automation in industrial environments. As a critical component of GE’s Series 90-30/70 PLC architecture, the IC695CRH004 integrates advanced processing capabilities with flexible communication protocols, making it ideal for complex manufacturing, energy, and process control applications. Its dual-core processor and 64 MB of user memory enable real-time data handling and seamless integration with I/O modules, HMIs, and supervisory systems.

Featuring a rugged design with conformal coating, the IC695CRH004 withstands harsh conditions, including temperature fluctuations (0–60°C) and electromagnetic interference. It supports ladder logic, structured text, and function block programming, ensuring compatibility with legacy systems while enabling modern automation strategies. The module’s redundant power input (24–240V AC/DC) and hot-swappable design minimize downtime, critical for 24/7 operations. By combining high-speed processing (33.6 μs/kB) with built-in diagnostics, the IC695CRH004 enhances system efficiency and reduces maintenance complexity.

For industrial engineers, the GE IC695CRH004 represents a future-proof solution that bridges traditional PLC functionality with Industry 4.0 readiness. Its Ethernet connectivity (10/100 Mbps) and support for protocols like Modbus TCP and DNP3 enable remote monitoring and predictive analytics. Whether deployed in standalone machines or large-scale distributed control systems, the IC695CRH004 ensures precise control and data integrity, driving operational excellence across sectors.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC695CRH004 |

| Manufacturer | GE (General Electric) |

| Product Type | Programmable Automation Controller (PAC) |

| Processor | Dual-core 300 MHz |

| User Memory | 64 MB (battery-backed) |

| Communication Ports | 1x Ethernet (10/100 Mbps), 1x RS-485 |

| Input Voltage | 24–240V AC/DC |

| Power Consumption | 12W maximum |

| Operating Temperature | 0–60°C (32–140°F) |

| Storage Temperature | -40–85°C (-40–185°F) |

| Dimensions | 177 mm × 127 mm × 89 mm (6.97” × 5” × 3.5”) |

| Weight | 1.2 kg (2.65 lb) |

| Certifications | CE, UL, CSA |

| Programming Software | Proficy Machine Edition |

Main Features and Advantages

High-Speed Processing: The IC695CRH004’s dual-core processor executes ladder logic at 33.6 μs/kB, supporting high-frequency applications like robotics and motion control. Its 64 MB memory allows storage of large programs and historical data, facilitating advanced analytics.

High-Speed Processing: The IC695CRH004’s dual-core processor executes ladder logic at 33.6 μs/kB, supporting high-frequency applications like robotics and motion control. Its 64 MB memory allows storage of large programs and historical data, facilitating advanced analytics.

Flexible Communication: With built-in Ethernet and RS-485 ports, the module communicates seamlessly with third-party devices (e.g., drives, sensors) using protocols like Modbus, DNP3, and CIP. This versatility reduces dependency on gateways, streamlining system architecture.

Reliability and Redundancy: Conformal coating and wide voltage tolerance (24–240V AC/DC) ensure stable operation in extreme environments. Redundant power inputs and hot-swappable design enable maintenance without system shutdowns, critical for continuous processes.

Scalable Integration: The IC695CRH004 works with GE’s 1771/1785 I/O modules and supports expansion racks, accommodating up to 512 I/O points. Its compatibility with Proficy Machine Edition software simplifies configuration and troubleshooting.

Application Areas

The GE IC695CRH004 excels in industries requiring precision and scalability:

The GE IC695CRH004 excels in industries requiring precision and scalability:

- Manufacturing: Powers assembly lines, quality control systems, and robotic cells. For example, in automotive plants, it coordinates conveyor belts and welding robots, ensuring synchronization and minimizing errors.

- Energy: Manages power generation, distribution, and renewable energy systems. Its DNP3 support enables substation automation and grid optimization.

- Water/Wastewater: Controls pumps, valves, and SCADA systems in treatment plants, ensuring regulatory compliance and energy efficiency.

- Oil & Gas: Handles wellhead monitoring, pipeline control, and refinery processes, leveraging its rugged design for offshore and onshore environments.

By addressing sector-specific challenges—such as real-time data logging in pharmaceuticals or remote diagnostics in mining—the IC695CRH004 becomes a cornerstone of smart industrial ecosystems.

Related Products

IC695CPU315-CJ General Electric 20MB RX3i 1GHz

Installation and Maintenance

Installation Preparation:

Before installing the GE IC695CRH004, verify the backplane voltage (5V DC) and ensure proper grounding. Align the module with the RX7i chassis slot, secure it with captive screws, and connect Ethernet/serial cables using RJ-45 and terminal block connectors. Configure network settings via Proficy Machine Edition, assigning IP addresses and enabling protocols as needed.

Installation Preparation:

Before installing the GE IC695CRH004, verify the backplane voltage (5V DC) and ensure proper grounding. Align the module with the RX7i chassis slot, secure it with captive screws, and connect Ethernet/serial cables using RJ-45 and terminal block connectors. Configure network settings via Proficy Machine Edition, assigning IP addresses and enabling protocols as needed.

Maintenance Recommendations:

Regularly inspect the IC695CRH004 for loose connections or dust accumulation, particularly in high-humidity environments. Replace the backup battery every 5 years to preserve memory integrity. Monitor diagnostic LEDs (Power, Run, Fault) for system health and update firmware quarterly to address security patches. For redundant setups, test failover functionality annually to ensure reliability.

Regularly inspect the IC695CRH004 for loose connections or dust accumulation, particularly in high-humidity environments. Replace the backup battery every 5 years to preserve memory integrity. Monitor diagnostic LEDs (Power, Run, Fault) for system health and update firmware quarterly to address security patches. For redundant setups, test failover functionality annually to ensure reliability.

Product Warranty

The GE IC695CRH004 comes with a 1-year warranty covering defects in materials and workmanship. GE’s global support network provides 24/7 technical assistance, including firmware updates, troubleshooting guides, and rapid replacement services. In-stock units ensure delivery within 3 days of payment, minimizing downtime. This comprehensive support ensures long-term system performance and customer satisfaction.

The GE IC695CRH004 comes with a 1-year warranty covering defects in materials and workmanship. GE’s global support network provides 24/7 technical assistance, including firmware updates, troubleshooting guides, and rapid replacement services. In-stock units ensure delivery within 3 days of payment, minimizing downtime. This comprehensive support ensures long-term system performance and customer satisfaction.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com