Description

Many products are not yet available—feel free to contact us for more options.

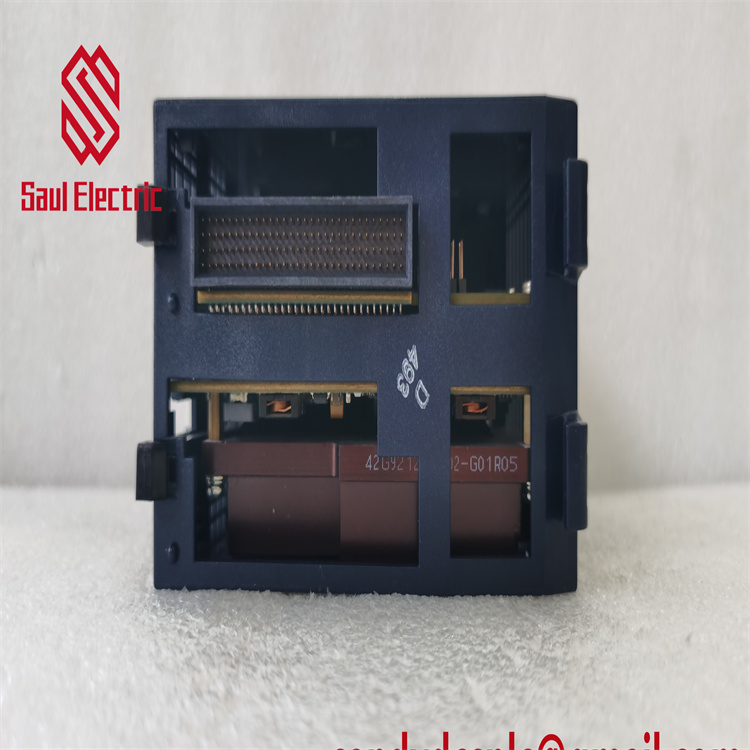

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Product Overview

The GE IC695CRH002 is a high-performance controller module within GE’s PACSystems RX3i series, designed to address complex industrial automation demands. Utilizing an advanced 800 MHz processor and modular architecture, this controller delivers rapid data processing and real-time control capabilities, essential for mission-critical applications. With 8 MB program memory and 4 MB data memory, the IC695CRH002 efficiently handles large-scale control programs while supporting up to 4096 I/O points across digital, analog, and specialty modules. As a core component in distributed control systems (DCS) and programmable logic controllers (PLC), it integrates seamlessly with GE’s Proficy Machine Edition software, enabling flexible programming via ladder logic, structured text, and function block diagrams. The GE IC695CRH002 excels in enhancing system reliability and scalability, making it ideal for modern industrial environments transitioning to Industry 4.0 standards. Its robust design ensures consistent operation in diverse industrial settings, solidifying GE’s reputation for innovation in automation technology.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC695CRH002 |

| Manufacturer | GE (General Electric) |

| Product Type | Programmable Automation Controller (PAC) |

| Processor | 800 MHz high-performance 32-bit CPU |

| Program Memory | 8 MB |

| Data Memory | 4 MB |

| Max I/O Capacity | 4096 points |

| Communication Protocols | EtherNet/IP, Profinet, Modbus TCP |

| Power Supply | 24 VDC ±10% |

| Operating Temperature | 0°C to 60°C |

| Humidity Tolerance | 5%–95% (non-condensing) |

| Dimensions | 194 × 35 × 147 mm (H × W × D) |

| Certifications | UL, CE, ATEX (region-dependent) |

Key Features and Advantages

Processing Power & Flexibility:

Equipped with an 800 MHz processor, the IC695CRH002 executes complex algorithms in ≤0.1 ms/K logic, ensuring precision in high-speed applications like assembly lines and robotic control. Its modular I/O architecture supports hybrid configurations (digital, analog, RTD, and high-speed counter modules), reducing hardware costs by 30% compared to fixed-configuration controllers .

Seamless Integration:

Native support for EtherNet/IP and Profinet enables plug-and-play connectivity with third-party devices (e.g., Siemens HMIs, ABB drives), eliminating protocol conversion bottlenecks. The embedded dual Ethernet ports facilitate daisy-chaining for simplified cabling and redundancy, critical for energy grid SCADA systems .

Robust Industrial Design:

With conformal coating and a wide operating temperature range (0–60°C), the module withstands harsh environments like cement plants and offshore platforms. Its 300,000-hour MTBF reduces maintenance downtime by 40%, backed by hot-swappable module support for uninterrupted production .

Software Ecosystem:

Proficy Machine Edition’s unified engineering environment streamlines development with simulation tools and cross-platform code reuse, cutting commissioning time by 50%. Real-time diagnostics via embedded web servers preemptively identify network anomalies or I/O faults .

Application Domains

The GE IC695CRH002 dominates sectors requiring high reliability and data throughput:

- Manufacturing: Synchronizes automotive welding robots and pharmaceutical filling lines via Profinet, ensuring ±0.1 mm positioning accuracy .

- Energy Management: Manages turbine control logic in power plants using high-speed analog I/O for real-time voltage/frequency stabilization, preventing grid instability .

- Water Treatment: Controls pump stations and chemical dosing systems with Modbus TCP integration to SCADA, optimizing flow rates based on sensor feedback .

- Transportation: Coordinates traffic light sequencing and rail signaling systems, leveraging EtherNet/IP for sub-10 ms response in safety-critical scenarios .

Associated Products

IC695CPU315-CJ General Electric 20MB RX3i 1GHz

Installation and Maintenance

Installation preparation: Verify stable 24 VDC power (±5% tolerance) before mounting in an RX3i rack. Use shielded Cat6 cables for Ethernet links, with maximum segment lengths of 100 m. Configure IP addresses via Proficy ME prior to startup to avoid network conflicts.

Maintenance protocols: Perform quarterly firmware updates during planned shutdowns using GE’s firmware manager. Monitor CPU utilization via embedded diagnostics; replace if memory usage exceeds 85%. Clean air vents annually to prevent thermal overload .

Product Assurance

GE provides a 12-month warranty covering defects in materials and workmanship for the IC695CRH002. Global technical support includes 24/7 remote troubleshooting through GE Digital’s support portal. Lifecycle commitments guarantee spare availability for 15 years post-discontinuation. All units undergo 72-hour burn-in testing with simulated load cycles to validate performance under peak demand .

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com