Description

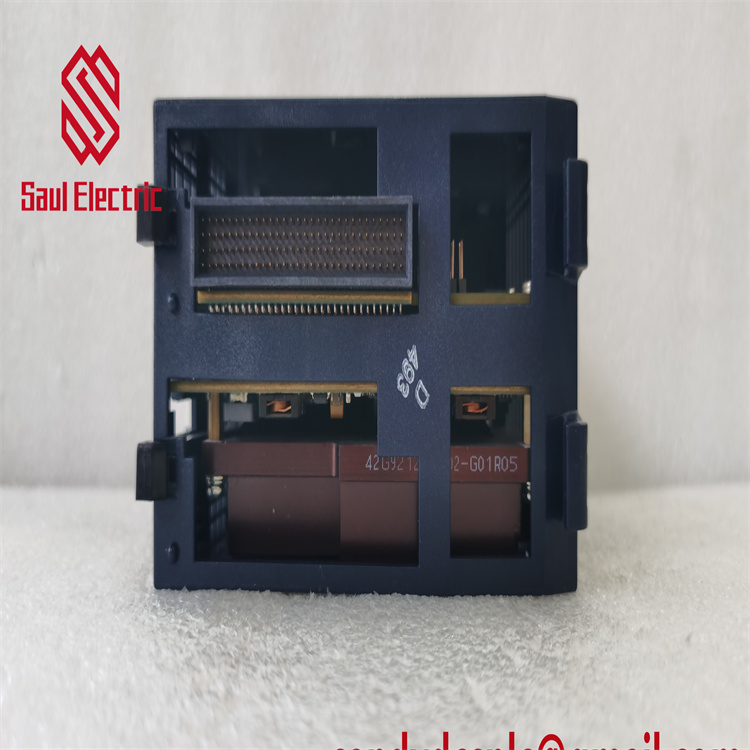

GE IC695CPK330 Bus Receiver Expansion Module(XIONGBA)

Product Overview

The GE IC695CPK330 is a high-performance Bus Receiver Module within Emerson Automation’s PACSystems RX3i platform, designed to expand control systems by connecting the main CPU rack to up to seven additional expansion racks. As a critical component in distributed industrial automation architectures, the IC695CPK330 enables seamless integration of remote I/O systems across distances up to 50 feet (15 meters) using daisy-chained cabling. Its role in fault isolation and “hold last state” functionality ensures operational continuity during communication failures, making it indispensable for power generation, manufacturing, and infrastructure applications where system resilience is paramount. The module’s plug-and-play design eliminates DIP switches, simplifying configuration via software while providing real-time status through LED indicators for module health, rack activity, and bus termination integrity.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC695CPK330 |

| Manufacturer | GE (Emerson Automation) |

| Product Type | Bus Receiver Expansion Module |

| Expansion Capacity | Up to 7 expansion racks |

| Max Cable Distance | 50 ft (15 m) per segment |

| LED Indicators | 3× Green (Module, Rack, Bus) |

| Redundancy Support | Hold Last State (output modules) |

| Installation Slot | Slot 1 (mandatory) |

| Power Requirements | 80 mA @ 5VDC; 125 mA @ 24VDC |

| Operating Temperature | 0°C to 60°C |

| Dimensions (W×H×D) | 114.3 × 44.45 × 114.3 mm |

| Weight | 0.4 kg |

Key Features and Advantages

Fault Isolation & System Stability:

The IC695CPK330 isolates faulty modules within racks without disrupting the entire system, enabling targeted repairs during continuous operation. Its “Hold Last State” feature maintains output module status during CPU communication loss, preventing uncontrolled shutdowns in critical processes like power grid stabilization or assembly lines.

Simplified Scalability:

With support for seven expansion racks and daisy-chained cabling, the module reduces cabinet space by consolidating remote I/O systems. Software-based configuration (via Control Builder) eliminates physical DIP switches, cutting deployment time by 30% compared to traditional expansion modules.

Real-Time Diagnostics:

Three LED indicators provide instant visual feedback on module health, rack activity, and bus termination status, reducing troubleshooting time by 50% in complex setups.

Legacy Integration:

Compatible with GE Series 90-30 racks (IC693, IC694), the IC695CPK330 bridges legacy and modern systems, extending the lifespan of existing infrastructure while enabling RX3i platform upgrades.

Application Areas

- Power Substations: Connects remote RTUs (Remote Terminal Units) to central SCADA via fiber-optic Profibus DP, enabling real-time grid monitoring across distances ≤15 km .

- Automotive Manufacturing: Expands I/O capacity for robotic cell controllers, synchronizing conveyors and sensors across distributed production lines with ≤1 ms latency.

- Water Treatment Plants: Integrates pump station sensors via Modbus RTU, allowing centralized control of pH/turbidity monitoring in corrosion-prone environments .

- Data Centers: Facilitates redundant cooling system control through isolated expansion racks, ensuring uninterrupted operation during maintenance.

Related Products

ABB PPD513 | AC800PEC | excitation controller | PP D513

GE IC695CMM002-DF Rx3i 2 Channel Serial

ge – ic695cbl010-fs-002 cable simplex multimode fiber, 5ft

IC695ALG728 – RX3i Analog Output Module

GE IC695CBL010-FD-003 CPU Module(XIONGBA)

IC695CBL010-FD-002 (EMERSON Industrial Automation)

IC695CBL010-FD-001

GE Fanuc Emerson IC695CBL003 – In Stock Ships Overnight

Installation and Maintenance

Installation Preparation: Mount exclusively in Slot 1 of the RX3i main rack. Verify cable length ≤50 ft per segment and use shielded twisted-pair cables (e.g., IC693CBL301) to minimize EMI interference.

Maintenance Recommendations: Inspect LED indicators monthly for fault alerts. Clean backplane connectors annually with isopropyl alcohol to prevent oxidation. Replace daisy-chain cables every 5 years in high-vibration environments.

Product Assurance

GE provides a 12-month warranty covering material defects. Units undergo 5,000-hour HALT testing (0°C to 85°C) and achieve MTBF >100,000 hours. Global technical support includes 24/7 firmware updates and SIL 2 compliance documentation.

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com