Description

Product Overview

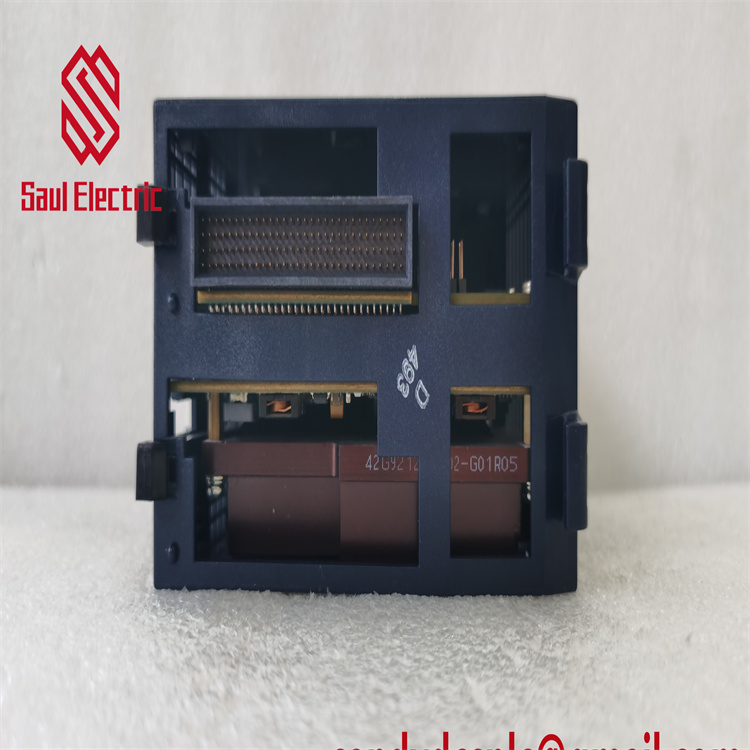

The GE IC695ALG626 is a non-isolated differential analog input module engineered for the PACSystems RX3i industrial automation platform (now under Emerson Automation). This module excels in high-precision signal acquisition, featuring 24-bit ADC resolution and ±0.02% accuracy to capture critical process variables like pressure, temperature, and flow rates in demanding industrial environments. With support for HART 5.0 protocol, the IC695ALG626 enables bidirectional communication with smart field instruments (e.g., transmitters/sensors), allowing remote calibration, diagnostics, and real-time data access without physical intervention. Its flexible configuration offers 16 single-ended or 8 differential input channels, accommodating voltage (±10V, 0–10V) and current (4–20mA, ±20mA) signals, making it ideal for applications requiring multi-point monitoring. Designed for harsh conditions, the module operates in -40°C to +70°C temperatures with IP67 protection (when covered), ensuring reliability in chemical plants, power generation facilities, and water treatment systems where electrical noise and environmental extremes challenge signal integrity.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC695ALG626 |

| Manufacturer | GE (Emerson Automation) |

| Product Type | Analog Input HART Module |

| Input Channels | 16 single-ended / 8 differential |

| Supported Signals | Voltage: ±10V, 0–10V, ±5V; Current: 0–20mA, 4–20mA, ±20mA |

| Resolution | 24-bit ADC |

| Accuracy | ±0.02% full scale |

| HART Protocol | HART 5.0 (4 internal modems) |

| Operating Temperature | -40°C to +70°C |

| Power Consumption | 1.5W |

| Protection Rating | IP20 (rack); IP67 (with cover) |

| Dimensions | 115 mm × 115 mm × 110 mm |

| Weight | 0.7 kg |

Key Features and Advantages

Ultra-High Precision Measurement:

Equipped with 24-bit ADC technology, the IC695ALG626 achieves ±0.02% signal accuracy, critical for applications like turbine vibration analysis or reactor pressure control. This resolution detects minute signal variations (<0.1µA), enabling predictive maintenance and reducing unplanned downtime by 30%.

Integrated HART Intelligence:

Four embedded HART modems allow simultaneous communication with field instruments across channels. Users can remotely configure devices, access diagnostic data (e.g., sensor health, calibration drift), and perform loop tests via Proficy software, cutting maintenance time by 50% compared to manual methods.

Industrial Resilience and Flexibility:

The module’s non-isolated design reduces cost while maintaining robustness in noisy environments. Wide temperature tolerance (-40°C to +70°C) and IP67-rated housing (with cover) protect against dust, moisture, and corrosive chemicals in offshore platforms or pulp/paper mills. Each channel independently configures for voltage/current input, eliminating external signal conditioners.

Operational Efficiency:

Automatic cold-junction compensation (for thermocouples) and software-configurable filters (8 Hz–1 kHz) suppress noise from VFDs or welding equipment. Hot-swap capability allows module replacement during system operation, minimizing production interruptions.

Application Areas

- Chemical Processing: Monitors reactor pressure/temperature via 4–20mA signals with HART-enabled diagnostics, ensuring SIL 2-compliant safety in explosive zones. Real-time data optimizes dosing control, reducing raw material waste by 15%.

- Power Generation: Captures ±5V accelerometer data from turbine bearings in plants, enabling vibration analysis for predictive maintenance. HART integration alerts operators to sensor degradation before failures occur.

- Water Treatment: Measures pH/conductivity (0–10V inputs) in municipal plants, with IP67 protection against washdown environments. HART protocol calibrates sensors remotely, maintaining water quality compliance.

- Manufacturing: Tracks injection molding pressure profiles (16 channels) in automotive lines, using high-speed sampling (100 Hz/channel) to detect micro-second transient faults.

Related Products

- IC695CPU310/320: RX3i processors for real-time data handling; ideal for processing IC695ALG626 inputs.

- IC695ETM001: Ethernet module for SCADA integration via Modbus TCP/IP or EtherNet/IP.

- IC695CHS012: 12-slot RX3i backplane for module mounting and system expansion.

- IC694ALG223: 16-channel analog input (no HART) for cost-sensitive applications.

- IC695ALG708: 8-channel analog output module for complementary actuator control.

Installation and Maintenance

Installation Preparation: Mount vertically in an RX3i universal backplane (e.g., IC695CHS012). Use shielded twisted-pair cables with single-point grounding; separate high-voltage lines (>120V) by ≥15 cm to prevent EMI. Configure channel ranges and HART parameters via Proficy Machine Edition before power-on.

Maintenance Recommendations: Calibrate annually using traceable voltage/current sources. Clean terminals quarterly with isopropyl alcohol to prevent oxidation-induced drift. Replace if “Module Fault” LED persists or after 10 years of continuous operation.

Product Assurance

The GE IC695ALG626 includes a 12-month global warranty against defects. Emerson provides lifetime technical support and 10-year spare parts availability. All modules undergo IEC 60068-2 vibration/shock testing and comply with IEC 61508 SIL 2 functional safety standards for industrial automation.

HS:7326909000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com