Description

Product Overview

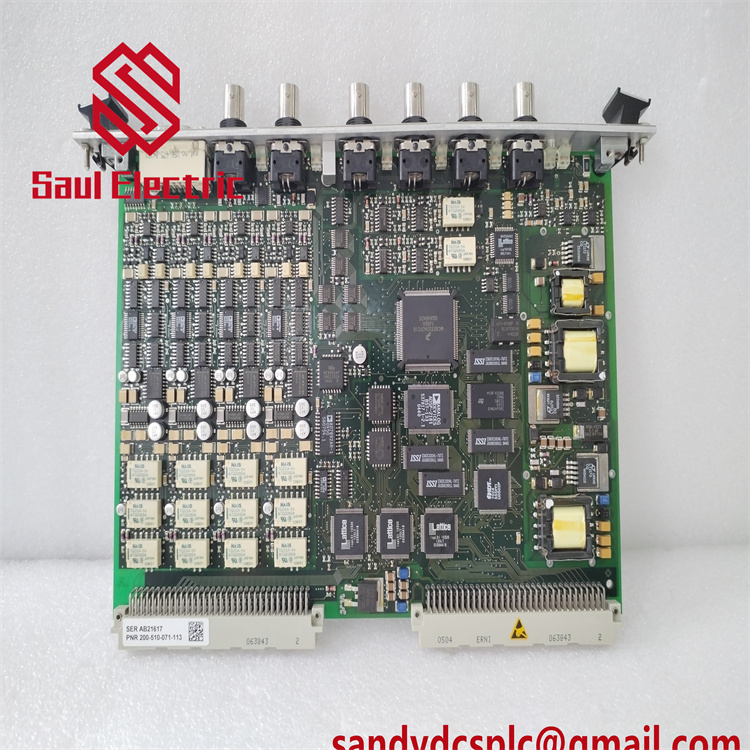

The GE VM600 MPC4 is a high-performance mechanical protection card designed for real-time monitoring and analysis of critical machinery in industrial automation systems. Belonging to the VM600 series from GE’s Vibro-Meter® product line, this module serves as a cornerstone in turbine control, compressor monitoring, and other safety-critical applications. With 4 dynamic channels and 2 tachometer (speed) channels, the GE VM600 MPC4 supports a wide range of sensors, including accelerometers, displacement probes, and proximity sensors, enabling precise measurement of parameters such as relative/absolute vibration, eccentricity, and thrust position.

Engineered with DSP technology, the GE VM600 MPC4 delivers real-time signal processing, including digital filtering, integration/differentiation, and order tracking. Its SIL 2 certification ensures compliance with safety integrity requirements for applications in hazardous environments, while ATEX and IECEx certifications make it suitable for explosive atmospheres. The module’s adaptive alarm settings and self-diagnostic capabilities detect anomalies in sensor signals or communication errors, minimizing downtime and enhancing operational reliability.

In automation systems, the GE VM600 MPC4 acts as a bridge between field devices and control systems, providing analog outputs (0–10 V or 4–20 mA) and relay outputs for actuation. Its hot-swappable design allows for maintenance without system shutdown, while Modbus RTU/RS485 communication simplifies integration into existing DCS or PLC networks. Whether in oil refineries, power plants, or chemical facilities, the GE VM600 MPC4 ensures continuous operation and protection of critical assets.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | GE VM600 MPC4 |

| Manufacturer | GE (Vibro-Meter®) |

| Product Type | Mechanical Protection Card |

| Input Channels | 4 dynamic + 2 tachometer (speed) |

| Input Voltage | 24 VDC (power supply) |

| Signal Compatibility | Accelerometers, proximity probes, speed sensors |

| Output Type | Analog (0–10 V/4–20 mA), relay outputs |

| Communication Protocol | Modbus RTU/RS485 |

| Safety Integrity Level (SIL) | SIL 2 |

| Environmental Rating | IP40 (Indoor use), ATEX/IECEx-certified |

| Operating Temperature | -20°C to +70°C |

| Physical Dimensions | 262 mm x 20 mm x 187 mm |

| Weight | 0.40 kg |

Key Features and Advantages

Multi-Channel Signal Processing: The GE VM600 MPC4 supports 4 dynamic channels for vibration analysis and 2 tachometer channels for speed monitoring, all independently configurable. Its DSP algorithms enable real-time filtering, amplitude/phase tracking, and adaptive alarm thresholds based on operational conditions.

Safety-Critical Compliance: With SIL 2 certification and ATEX/IECEx compliance, the module ensures fail-safe operation in hazardous environments. The SIL 2-rated design meets rigorous safety standards for applications such as emergency shutdown systems and turbine protection.

Hot-Swap Capability: The GE VM600 MPC4 allows for live replacement of modules without disrupting system operation, reducing maintenance downtime. This feature is critical in continuous-process industries where downtime equates to significant financial loss.

Sensor Power Integration: The module provides built-in power supply for IEPE accelerometers and proximity probes, simplifying wiring and reducing external components. Buffered outputs enable direct connection to oscilloscopes or data loggers for waveform analysis.

Flexible Configuration: Users can program alarm setpoints, time delays, and hysteresis via GE’s VibroSight System Manager software. The module supports both metric and imperial units, accommodating global industrial standards.

Application Areas

The GE VM600 MPC4 is widely used in industries requiring high-precision machinery monitoring:

- Oil and Gas: Monitors turbine compressors, pumps, and wellhead equipment for vibration anomalies, ensuring compliance with API 670 standards.

- Power Generation: Supports steam turbine control, generator bearing health monitoring, and boiler feedwater pump protection in thermal and nuclear power plants.

- Chemical Processing: Detects early signs of equipment degradation in reactors, centrifuges, and agitators, preventing catastrophic failures in hazardous environments.

- Metals and Mining: Enhances reliability of crushers, conveyors, and mills by providing real-time vibration analysis and predictive maintenance insights.

- Water Treatment: Ensures optimal performance of pumps, blowers, and mixers in wastewater treatment plants through continuous condition monitoring.

Related Products

- GE VM600 IOC4T: Input/output card paired with MPC4 for analog/digital signal conditioning and relay control.

- GE VM600 RLC16: 16-channel relay card for alarm actuation and system shutdowns.

- GE VM600 AMC8: 8-channel analog monitoring card for temperature and process parameter surveillance.

- GE VM600 CPUM: Modular CPU card for system control and Modbus TCP/PROFINET communication.

- GE VM600 CMC16: 16-channel dynamic signal analyzer for advanced vibration diagnostics.

- GE VM600 IRC4: Intelligent relay card with configurable logic for complex protection schemes.

- GE VM600 XMX16: Extended measurement card for high-speed data acquisition and FFT analysis.

- GE VM600 AME8: 8-channel analog output card for closed-loop control applications.

- GE VM600 IQS450: Proximity probe interface module for displacement measurements.

- GE VM600 EA402: Extension cable for vibration sensors, ensuring signal integrity over long distances.

Installation and Maintenance

Installation Preparation:

Ensure the VM600 ABE04x rack is properly grounded and ventilated. Use IOC4T cards to terminate field wiring, following the pinout diagram provided in the user manual. Verify the 24 VDC power supply and connect the module to the rack using keyed connectors to prevent misalignment.

Ensure the VM600 ABE04x rack is properly grounded and ventilated. Use IOC4T cards to terminate field wiring, following the pinout diagram provided in the user manual. Verify the 24 VDC power supply and connect the module to the rack using keyed connectors to prevent misalignment.

Maintenance Recommendations:

- Routine Checks: Inspect front-panel LEDs monthly to verify channel status. Use VibroSight System Manager to perform diagnostic tests and firmware updates.

- Sensor Calibration: Calibrate accelerometers and proximity probes annually to maintain accuracy. Replace worn or damaged sensors immediately.

- Environmental Monitoring: Clean dust from ventilation slots quarterly and ensure ambient temperature remains within -20°C to +70°C.

- Spare Parts Inventory: Keep a spare GE VM600 MPC4 module on hand for rapid replacement during unexpected failures.

Product Assurance

GE guarantees the GE VM600 MPC4 against defects in materials and workmanship for 1 year from delivery. Our global technical support team provides 24/7 assistance for installation, troubleshooting, and firmware updates. With a dedicated inventory of spare parts and a streamlined logistics network, we ensure 3-day delivery after payment to minimize operational disruptions.

For mission-critical applications, GE offers extended warranties and predictive maintenance programs to optimize system performance and lifecycle costs. All products undergo rigorous testing to meet ISO 9001 and IEC 61508 standards, ensuring compliance with the highest industry benchmarks.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com