Description

Product Overview

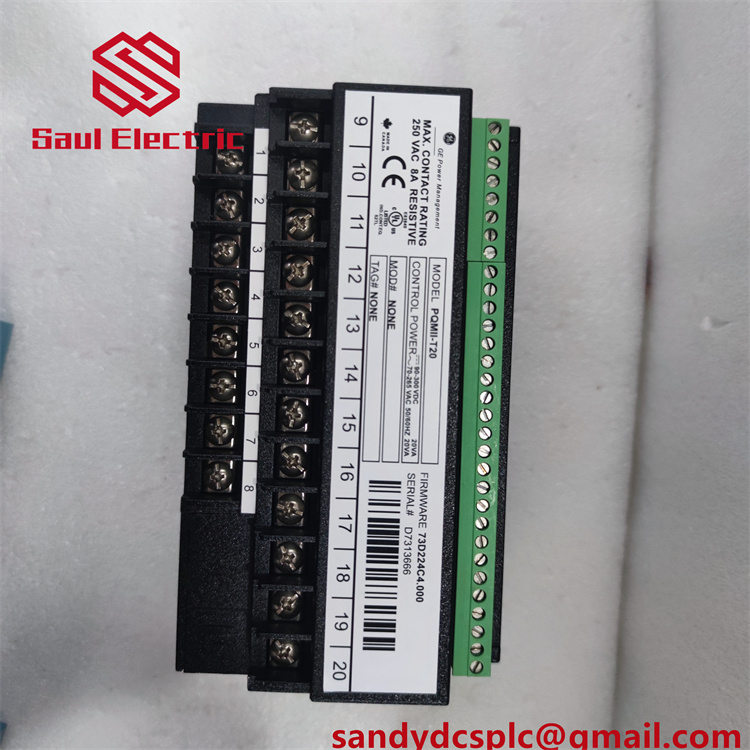

The GE PQMII-T20 is a three-phase power quality monitoring module engineered for real-time analysis of electrical systems in industrial, commercial, and utility applications. As part of GE’s PQM II series, this compact device delivers comprehensive metering of voltage, current, power, harmonics, and energy usage, enabling proactive identification of power quality issues such as voltage sags, swells, and transient disturbances. The GE PQMII-T20 features four isolated analog outputs (0-20 mA/4-20 mA) and four programmable relay outputs, allowing seamless integration with SCADA systems, PLCs, and distributed control architectures13.

Equipped with Modbus RTU/RS485 communication and optional Ethernet connectivity, the GE PQMII-T20 supports remote configuration and data logging of up to 10,000 events, ensuring compliance with industry standards like IEEE 1159. Its true RMS measurement technology guarantees ±0.5% accuracy across a wide voltage range (20–60 VDC/20–48 VAC) and frequencies (50/60 Hz), making it ideal for critical environments such as power plants, data centers, and renewable energy installations27. The module’s waveform capture and harmonic analysis capabilities (up to 50th harmonic) provide granular insights into power system health, while its -40°C to +85°C operating range and conformal-coated PCB ensure reliability in harsh industrial conditions48.

Refurbished GE PQMII-T20 units undergo rigorous testing to meet OEM standards, offering a cost-effective solution for retrofitting legacy systems or upgrading power monitoring infrastructure. With hot-swap capabilities and intuitive front-panel controls, the module minimizes downtime during maintenance or expansion1011.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | GE PQMII-T20 |

| Manufacturer | General Electric (GE) |

| Product Type | Three-Phase Power Quality Monitoring Module |

| Voltage Range | 20–60 VDC / 20–48 VAC (50/60 Hz) |

| Current Range | 0–5 A RMS (with external CTs) |

| Accuracy | ±0.5% of reading for voltage, current, and power |

| Harmonic Analysis | Up to 50th harmonic (voltage/current) |

| Communication | RS485 (Modbus RTU), optional Ethernet (DNP 3.0) |

| Analog Inputs | 1x 4–20 mA (for external sensor integration) |

| Analog Outputs | 4x isolated 0–20 mA/4–20 mA |

| Relay Outputs | 4x programmable SPDT (125 VAC/30 VDC, 5 A) |

| Data Logging | Internal memory for 10,000+ events |

| Operating Temperature | -40°C to +85°C |

| Dimensions (WxHxD) | 144 mm x 144 mm x 52 mm (5.67” x 5.67” x 2.05”) |

| Weight | 1.5 kg (3.31 lbs) |

| Certifications | CE, FCC Class A, RoHS |

Key Features and Advantages

Comprehensive Power Quality Analysis:

- Monitors 18+ parameters including real/reactive/apparent power, power factor, and energy consumption, providing a holistic view of electrical system performance511.

- Waveform capture and voltage disturbance recorder (VDR) capabilities identify transient events (e.g., voltage dips) for root-cause analysis in mission-critical applications37.

Flexible Integration:

- Supports Modbus RTU and optional Ethernet/IP protocols, enabling seamless integration with GE’s Proficy software suite and third-party SCADA systems28.

- Four isolated analog outputs and programmable relays facilitate closed-loop control (e.g., power factor correction or load shedding)13.

Rugged Industrial Design:

- Conformal coating and wide temperature tolerance ensure reliability in extreme environments, including offshore platforms and manufacturing plants48.

- Fanless design reduces maintenance needs, while hot-swap functionality allows module replacement without system downtime1011.

Cost-Effective Solution:

- Refurbished units with 1-year warranties offer significant savings compared to new replacements, ideal for retrofitting legacy power monitoring systems110.

- Compact 144 mm x 144 mm form factor minimizes space requirements in switchgear and control panels25.

Application Areas

-

Industrial Automation:

- Monitoring power quality in CNC machinery, conveyor systems, and robotics to prevent equipment damage and optimize energy efficiency711.

-

Power Generation & Utilities:

- Real-time analysis of voltage stability in substations, wind farms, and solar installations to ensure grid compliance and maximize energy output411.

-

Commercial Buildings:

- Detecting harmonics and voltage fluctuations in data centers, hospitals, and office complexes to protect sensitive equipment (e.g., servers, medical devices)711.

-

Oil & Gas:

- Ensuring reliable power supply in offshore platforms and refineries through continuous monitoring of transient events and power factor correction48.

-

Smart Grid Management:

- Enabling predictive maintenance by logging voltage sags/swells and harmonics data for grid operators and energy service providers37.

Related Products

-

GE PQMII-T20-C-A:

- Enhanced variant with expanded voltage range (70–265 VAC) and Ethernet connectivity, suitable for high-voltage industrial applications17.

-

GE PQMII-T20-A:

- DNP 3.0-compatible model with advanced harmonic analysis and waveform capture, ideal for utility-scale power monitoring37.

-

GE Multilin 700 Series:

- High-end power meters offering advanced analytics and cybersecurity features for mission-critical infrastructure11.

-

GE VME-5565:

- VMEbus reflective memory card for synchronizing real-time data between GE PQMII-T20 and distributed control systems10.

-

GE Enervista MMII Software:

- Configuration tool for remote parameter tuning and data visualization, compatible with GE PQMII-T20 networks10.

Installation and Maintenance

Pre-Installation Preparation:

- Verify compatibility with 20–60 VDC/20–48 VAC power supply and ensure proper CT/PT wiring for current/voltage measurement. Use the GE PQMII-T20 hardware manual to configure Modbus addresses and relay setpoints via front-panel buttons or Enervista software911.

Maintenance Recommendations:

- Inspect CT/PT connections quarterly for corrosion or loose wiring. Clean the module’s exterior with a dry cloth to prevent dust buildup in high-humidity environments. Schedule annual firmware updates to address security vulnerabilities and enhance compatibility810.

- For critical systems, maintain spare modules to minimize downtime. Replace batteries (if equipped) every 5 years to preserve data logging functionality911.

Product Assurance

The GE PQMII-T20 is backed by a 1-year warranty on refurbished units, covering defects in materials and workmanship. GE-certified technicians provide 24/7 technical support for installation, calibration, and troubleshooting. Spare parts and repair services are available through authorized partners, ensuring long-term system maintainability110. While discontinued, the module’s robust design and widespread use in legacy systems make it a reliable choice for industrial operators prioritizing power quality and operational continuity.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com