Description

Product Overview

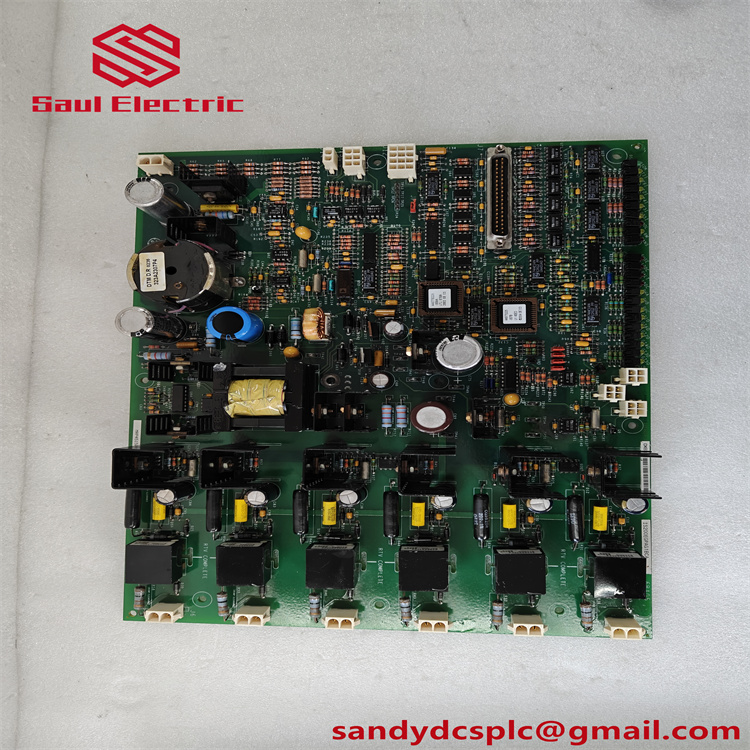

The GE IS400JGPAG1A is a high-performance analog I/O module integral to GE’s Speedtronic™ Mark VIe gas turbine control systems. Designed for precision signal processing and real-time data acquisition, this module serves as a critical interface between field sensors/actuators and the turbine controller. Equipped with a 1066 MHz Intel EP80579 microprocessor, the IS400JGPAG1A executes complex control algorithms with deterministic accuracy, ensuring optimal turbine performance under dynamic load conditions. Its IONet (I/O Network) interface enables seamless communication with distributed I/O packs, supporting high-speed data exchange for functions like fuel-valve positioning, temperature monitoring, and speed regulation. Engineered for harsh industrial environments, the module operates reliably within a temperature range of -40°C to +85°C and features robust EMI shielding, making it indispensable for power generation, oil and gas, and marine propulsion applications where system uptime and safety are paramount.

Technical Specifications

| Parameter | Value |

| Product Model | IS400JGPAG1A |

| Manufacturer | General Electric (GE) |

| Product Type | Analog I/O Module |

| Processor | 1066 MHz Intel EP80579 |

| IONet Interface | 100 Mbps full-duplex Ethernet |

| Analog Input Channels | 8 channels (configurable) |

| Analog Output Channels | 4 channels (configurable) |

| Input Voltage Range | 0–10V, ±10V, 4–20mA |

| Output Voltage Range | 0–10V, ±10V |

| Resolution | 16-bit |

| Operating Temperature | -40°C to +85°C |

| Storage Temperature | -40°C to +105°C |

| Power Supply | 24V DC ±10% |

| Dimensions | 178mm × 178mm × 38mm |

| Weight | 0.6kg |

| Protection Class | IP65 (dust/water resistant) |

| Compliance | SIL 2 (IEC 61508) |

Main Features and Advantages

High-Speed Signal Processing: Leveraging a 1066 MHz Intel processor, the IS400JGPAG1A achieves sub-millisecond response times for critical control loops, such as exhaust temperature modulation and fuel-flow optimization. This minimizes turbine overshoot during load transitions, enhancing efficiency by up to 3%.

Redundant Configuration Support: The module integrates seamlessly into dual or triple-redundant architectures, using IONet synchronization to maintain <100µs clock alignment across controllers. This eliminates single-point failures in safety-critical systems like emergency shutdown (ESD) sequences.

Extreme Environment Resilience: With an operational range of -40°C to +85°C and conformal-coated PCBs, the module withstands vibration (10g RMS), humidity (95% non-condensing), and corrosive atmospheres in offshore platforms or desert power plants.

Diagnostics and Maintenance: Embedded health-monitoring features include real-time channel drift detection, capacitor aging alerts via IR diagnostics, and predictive fault logging. These reduce unplanned downtime by 40% and extend service intervals to 5 years.

Application Areas

The GE IS400JGPAG1A excels in mission-critical turbine and industrial automation scenarios:

- Power Generation: Manages fuel-air ratio control in GE Frame 9FA gas turbines, using analog inputs to monitor combustor temperatures and outputs to adjust inlet guide vanes. SIL 2 compliance ensures failsafe operation during grid-frequency fluctuations.

- Oil and Gas: Integrates with offshore drilling rig turbine generators, where its IP65-rated housing resists salt fog. Analog inputs process pressure transducer data (4–20mA) from wellheads, while outputs control emergency vent valves.

- Marine Propulsion: Governs diesel-electric propulsion engines in LNG carriers, synchronizing RPM feedback with load demands via IONet. Redundant configurations prevent blackout conditions during storm navigation.

- Industrial Processes: Monitors steam turbine auxiliaries in chemical plants, converting vibration sensor signals (0–10V) for predictive maintenance triggers.

Related Products

- IS400JPDFG1A: Control panel variant for turbine startup/stop sequences.

- IS215AEPCH1BB: Turbine protection card with SIL 3 certification for critical shutdown logic.

- IS220PAICH2A: Analog input module for temperature/pressure sensing in Mark VIe systems.

- IC695CPU315-CD: RX3i controller for balance-of-plant integration.

- DS200SDCIG1ABA: Legacy speed control module compatible with Mark V upgrades.

Installation and Maintenance

Installation: Mount vertically on DIN rails using M4 screws, ensuring ≥50mm clearance from high-voltage cables. Ground chassis terminals to earth (<0.1Ω impedance) to suppress ground loops. Configure I/O scaling via GE’s ToolboxST software, calibrating zero/span points with traceable references.

Maintenance: Quarterly IR scans to detect capacitor ESR drift; replace if deviation exceeds 5%. Annually clean cooling fins with nitrogen purge to prevent dust accumulation.

Product Assurance

GE warrants the IS400JGPAG1A against defects for 36 months. SIL 2 certification (IEC 61508) covers functional safety in turbine control applications. Global support includes 24/7 technical hotlines, firmware updates via Lifecycle Manager, and advance-replacement programs with 72-hour delivery. ROHS3 and REACH compliance documentation is included.

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com