Description

Product Overview

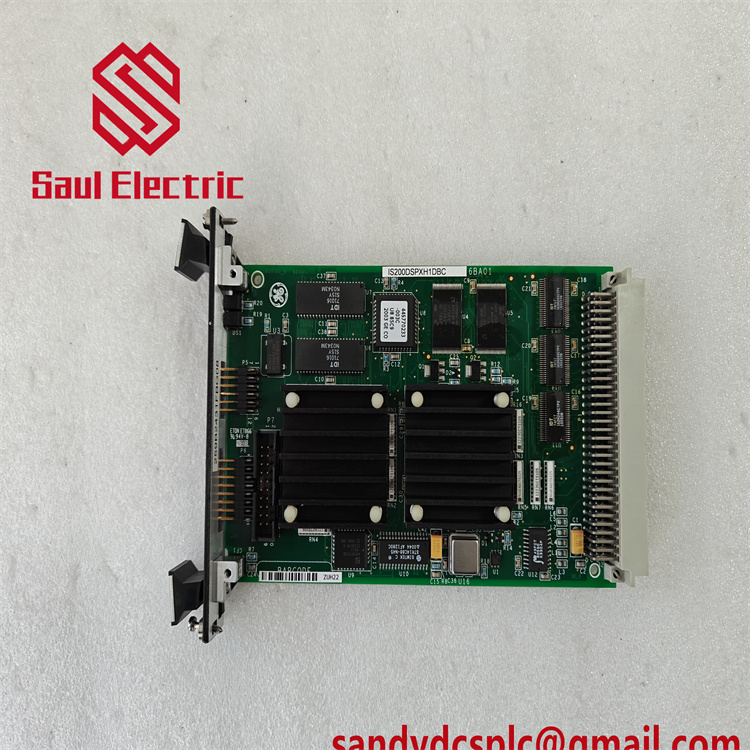

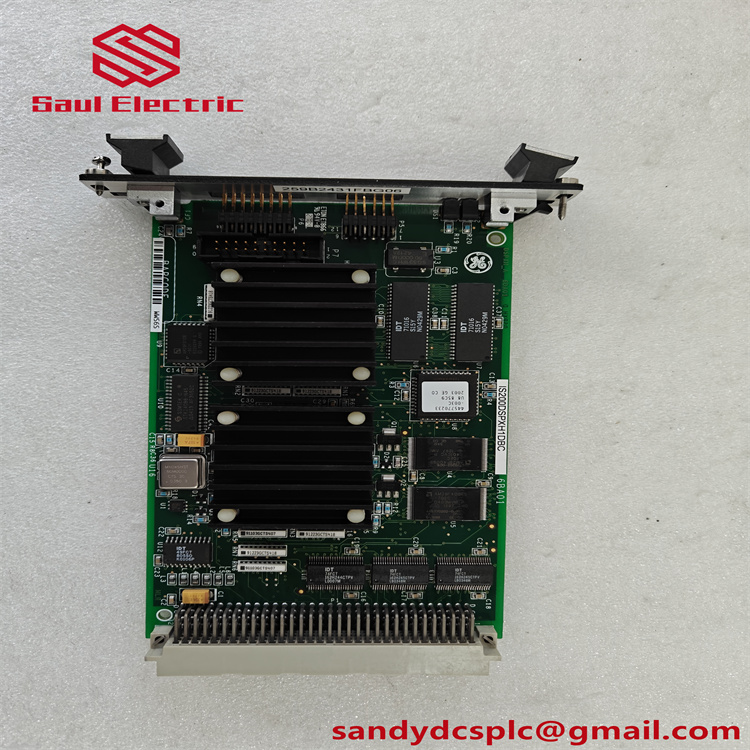

The GE IS230STAI2AH01 is a high-precision analog input module engineered for GE’s Mark VIe turbine control system, a cornerstone of industrial automation in power generation, oil & gas, and heavy machinery. Designed to interface with a wide range of sensors, this module delivers real-time data acquisition for critical applications such as turbine health monitoring, process control, and predictive maintenance. As part of the Mark VIe distributed I/O architecture, the IS230STAI2AH01 ensures seamless integration with GE’s advanced control systems, enabling precise measurement and analysis of analog signals in mission-critical environments .

The GE IS230STAI2AH01 is a high-precision analog input module engineered for GE’s Mark VIe turbine control system, a cornerstone of industrial automation in power generation, oil & gas, and heavy machinery. Designed to interface with a wide range of sensors, this module delivers real-time data acquisition for critical applications such as turbine health monitoring, process control, and predictive maintenance. As part of the Mark VIe distributed I/O architecture, the IS230STAI2AH01 ensures seamless integration with GE’s advanced control systems, enabling precise measurement and analysis of analog signals in mission-critical environments .

With 8 differential voltage inputs (e.g., 0-10V, ±10V) and 15-bit resolution, the IS230STAI2AH01 offers exceptional accuracy for monitoring parameters like shaft vibration, temperature, and pressure. Its software-configurable filters (2.3/4/4.7Hz) reduce noise in high-vibration settings, while 24/28Hz filters cater to specialized applications such as speed control in gas turbines. The module’s conformal-coated PCBs and -30°C to +65°C operating range ensure reliability in harsh industrial conditions, including offshore platforms and petrochemical plants. By supporting 24V DC redundant power inputs, the IS230STAI2AH01 minimizes downtime in fault-prone systems, making it ideal for continuous-operation environments .

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS230STAI2AH01 |

| Manufacturer | General Electric (GE) |

| Product Type | High-Precision Analog Input Module |

| Series | Mark VIe |

| Input Configuration | 8 differential voltage channels (0-10V, ±10V) |

| Resolution | 15-bit |

| Filter Options | Software-configurable (2.3/4/4.7Hz); 24/28Hz for specific applications |

| Power Supply | 24V DC (redundant support) |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Physical Dimensions | 16 cm x 16 cm x 12 cm (6.3″ x 6.3″ x 4.7″) |

| Weight | ~0.8 kg |

| Certifications | UL 508, CE, CSA |

Key Features and Advantages

High-Accuracy Signal Conditioning: The IS230STAI2AH01’s 15-bit resolution and low noise floor enable precise measurement of subtle changes in analog signals, critical for detecting early signs of turbine wear or process deviations. Its software-configurable filters allow customization for specific applications, ensuring optimal signal integrity in noisy environments .

High-Accuracy Signal Conditioning: The IS230STAI2AH01’s 15-bit resolution and low noise floor enable precise measurement of subtle changes in analog signals, critical for detecting early signs of turbine wear or process deviations. Its software-configurable filters allow customization for specific applications, ensuring optimal signal integrity in noisy environments .

Harsh Environment Resilience: With conformal-coated PCBs and an IP20-rated enclosure, the module resists dust, moisture, and EMI/RFI interference. Its -30°C to +65°C temperature range supports reliable operation in extreme conditions, while vibration-resistant design ensures stability in high-vibration settings like turbine installations .

Redundant Power and Diagnostics: The IS230STAI2AH01 supports dual 24V DC inputs for uninterrupted power supply, backed by LED indicators for real-time monitoring of power status, channel health, and fault conditions. User-configurable alarms for over-range, under-range, and open-circuit events simplify troubleshooting and reduce maintenance downtime .

Flexible Integration: Compatible with IS220PAICH1A/B analog I/O packs and IS200STAIH1A/B terminal boards, the IS230STAI2AH01 integrates seamlessly into Mark VIe systems. Its plug-and-play design eliminates manual configuration, while auto-reconfiguration via GE Control System Toolbox streamlines module replacement .

Application Areas

- Turbine Health Monitoring: Integrates with proximity probes and accelerometers to measure shaft vibration and axial displacement, enabling predictive maintenance and preventing catastrophic failures in gas and steam turbines .

- Temperature Control: Supports 4-wire RTD sensors for high-accuracy temperature monitoring in turbines and industrial processes, with lead resistance compensation for 3-wire configurations .

- Process Automation: Monitors pressure, flow, and level sensors in oil refineries and chemical plants, facilitating closed-loop control and optimizing operational efficiency .

- Power Generation: Provides real-time data for speed control, fuel metering, and safety interlocks in power plants, ensuring grid stability and compliance with environmental standards .

- Marine Propulsion: Enhances engine control systems in naval and commercial vessels by delivering precise analog inputs for propulsion and fuel efficiency optimization .

Related Products

IS220PTCCH1A Thermocouple Input Module

IS220PSVOH1A, REV E – Servo Control I/O Module

IS200STCIH6A DIN-Rail Contact Terminal Board

IS200SPROH1ABC – Emergency Protection Terminal Board

Is400jgpag1a-terminal-board-for-pccah1a

Installation and Maintenance

Installation Preparation: Ensure the Mark VIe backplane is powered off and grounded. Use GE Control System Toolbox software to configure channel settings, filter parameters, and power redundancy. Shielded twisted-pair cables (16 AWG max) are recommended to minimize signal interference. Verify compatibility with IS220PAICH1A/B packs and IS200STAIH1A/B terminal boards before installation .

Installation Preparation: Ensure the Mark VIe backplane is powered off and grounded. Use GE Control System Toolbox software to configure channel settings, filter parameters, and power redundancy. Shielded twisted-pair cables (16 AWG max) are recommended to minimize signal interference. Verify compatibility with IS220PAICH1A/B packs and IS200STAIH1A/B terminal boards before installation .

Maintenance Recommendations: Regularly inspect LED indicators for fault codes and clean dust from vents to prevent overheating. Replace worn fuses immediately and perform quarterly firmware updates to address security patches and performance optimizations. For high-vibration environments, check cable connections bi-annually. Annual preventive maintenance by certified GE technicians is advised for mission-critical applications .

Product Warranty

GE provides a 1-year warranty for the IS230STAI2AH01, covering defects in materials and workmanship. This includes free replacement or repair services, supported by a global network of certified technicians. Extended warranties and proactive maintenance plans are available for critical applications to further reduce downtime risks. Technical support is accessible 24/7 via phone, email, and GE’s online knowledge base, ensuring rapid resolution of operational challenges .

GE provides a 1-year warranty for the IS230STAI2AH01, covering defects in materials and workmanship. This includes free replacement or repair services, supported by a global network of certified technicians. Extended warranties and proactive maintenance plans are available for critical applications to further reduce downtime risks. Technical support is accessible 24/7 via phone, email, and GE’s online knowledge base, ensuring rapid resolution of operational challenges .

HS:8471800000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com