Description

Product Overview

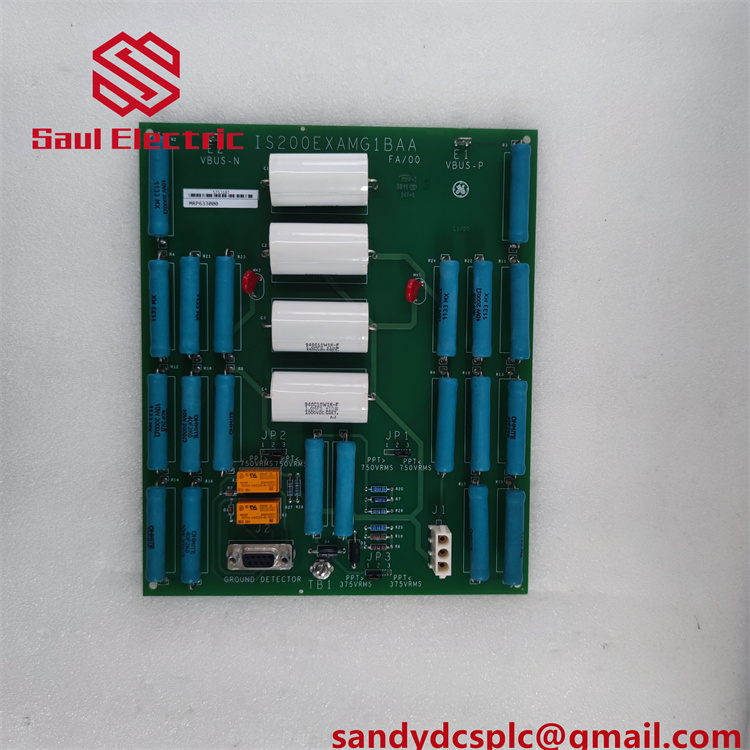

The GE IS230SRTDH2A, REV A is a high-performance RTD (Resistance Temperature Detector) Terminal Board designed by General Electric for critical temperature monitoring and control within Mark VI/Mark VIe Speedtronic Turbine Systems. Serving as a core component in industrial automation, this module interfaces with PRTD/VRTD sensors to deliver precise temperature data for gas turbine governors, exciters, and safety systems. Engineered for extreme environments, the GE IS230SRTDH2A, REV A operates reliably from -40°C to +85°C and features redundant architecture to ensure uninterrupted operation in power plants, offshore platforms, and heavy manufacturing facilities. Its compact, DIN-rail-mountable design simplifies integration into existing Mark VIe racks, while conformal-coated circuitry resists humidity, dust, and chemical corrosion. With UL/CE certifications and SIL 2 compliance, this module is indispensable for fail-safe turbine control where accuracy and redundancy are non-negotiable .

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS230SRTDH2A, REV A |

| Manufacturer | General Electric (GE) |

| Product Type | RTD Terminal Board |

| Input Voltage | 110V/220V AC (compatible with DC systems) |

| Operating Temperature | -40°C to +85°C |

| Storage Temperature | -55°C to +125°C |

| I/O Channels | 8 analog inputs, 2 analog outputs |

| Signal Compatibility | 1–5Vdc, ±5Vdc, ±10Vdc, 0–20mA, ±1mA |

| Redundancy Support | Yes (hot-swappable) |

| Dimensions | 9.25 × 7.5 × 1.5 inches (235 × 190 × 38 mm) |

| Weight | ~2 lbs (0.9 kg) |

| Certifications | UL, CE, RoHS |

| Compatible Systems | GE Mark VI/Mark VIe Turbine Control |

Key Features and Advantages

Precision Temperature Monitoring:

The GE IS230SRTDH2A, REV A supports high-accuracy RTD sensors (e.g., Pt100, Ni120) with 16-bit resolution, enabling ±0.1°C tolerance for critical processes like turbine exhaust monitoring. Its 8 configurable analog inputs handle diverse signal ranges (1–5Vdc to ±10Vdc), while dual outputs drive actuators for real-time temperature regulation .

Built-in Redundancy and Robustness:

Engineered with dual-path redundancy, the module automatically switches to a backup channel during failures, achieving >99.99% uptime in SIL 2-rated safety systems. The conformal-coated PCB and heat-resistant resin housing withstand 5G vibrations, 95% humidity, and corrosive atmospheres (e.g., offshore rigs, steel mills) .

Seamless Integration and Diagnostics:

Native compatibility with Mark VIe I/O processors (e.g., IS215UCVEH2AB) allows plug-and-play deployment via PROFIBUS or Ethernet/IP. Integrated diagnostics detect sensor drift, open circuits, and ground faults, reducing troubleshooting time by 40% using GE’s ToolboxST software .

Application Areas

- Power Generation: Monitors turbine bearing temperatures and exhaust gases in gas/steam plants, triggering emergency shutdowns to prevent equipment damage .

- Oil & Gas: Deployed on ATEX Zone 2-certified offshore platforms for compressor station temperature control, ensuring safe operations amid salt fog and methane exposure .

- Heavy Manufacturing: Manages thermal thresholds in high-vibration environments like rolling mills, preventing overheating in continuous production lines .

Related Products

IS220PTCCH1A Thermocouple Input Module

IS220PSVOH1A, REV E – Servo Control I/O Module

IS200STCIH6A DIN-Rail Contact Terminal Board

IS200SPROH1ABC – Emergency Protection Terminal Board

Is400jgpag1a-terminal-board-for-pccah1a

Installation and Maintenance

Installation: Mount vertically on DIN rails or Mark VIe backplanes with ≥20 cm clearance from high-voltage cables. Verify grounding resistance ≤0.1Ω and input voltage compatibility (110V/220V AC). Use shielded twisted-pair cables for RTD sensor connections to minimize EMI .

Maintenance: Clean air vents quarterly with dry nitrogen (<20 psi). Calibrate input channels annually using a Fluke 744 calibrator. Replace after 60,000 operational hours (≈7 years) or if diagnostic LEDs indicate signal degradation .

Product Assurance

GE offers a 12-month global warranty covering defects. Each IS230SRTDH2A, REV A undergoes MIL-STD-810H testing (thermal cycling, vibration, humidity) with an MTBF exceeding 150,000 hours. 24/7 remote diagnostics and 48-hour on-site support are available for critical failures in power generation sites .

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com