Description

Product Overview

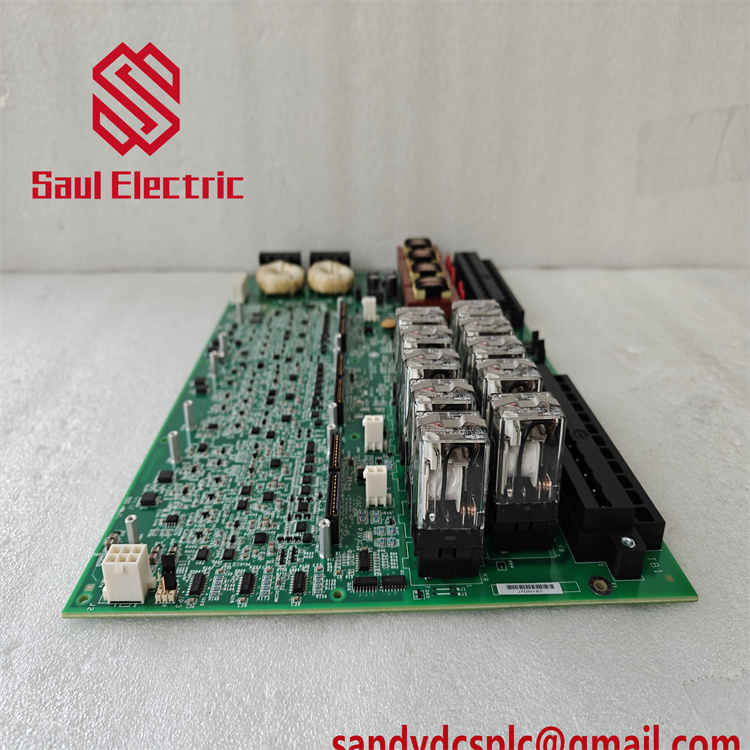

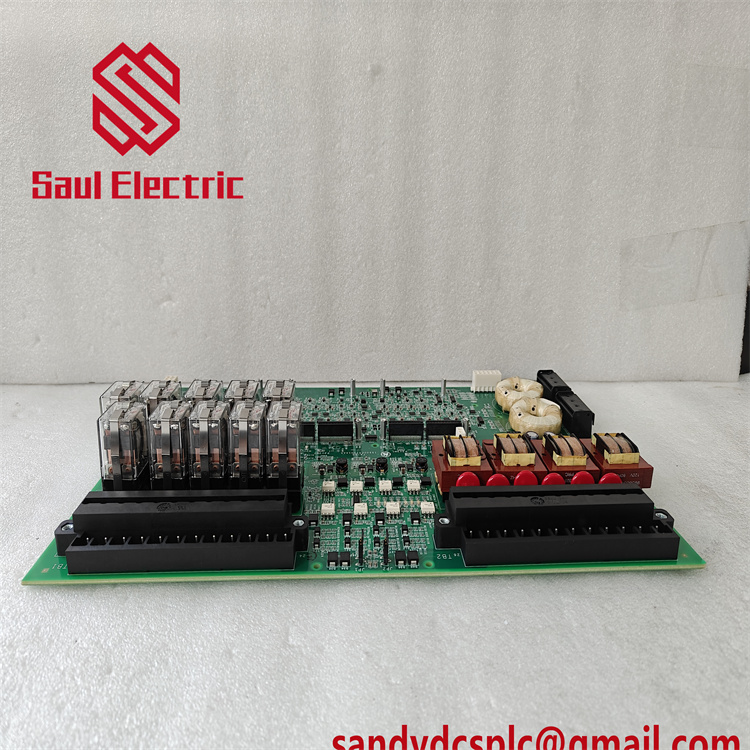

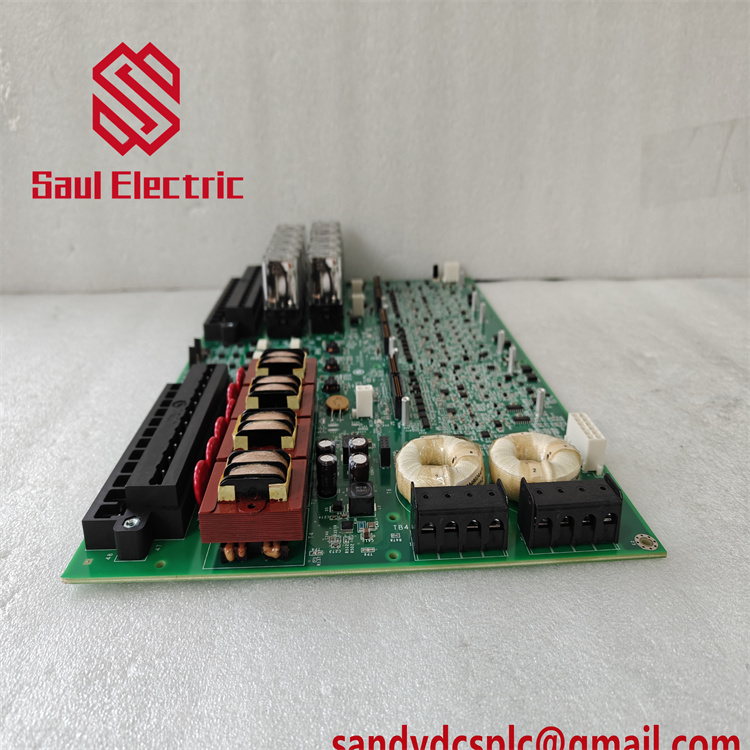

The GE IS220YDOAS1A REV G (also referred to as YDOA-H1A) is a Safety Discrete Output I/O Pack designed for GE’s SPEEDTRONIC™ Mark VIe gas turbine control system. This module provides high-reliability discrete output control and feedback monitoring for mission-critical applications in power generation, oil & gas, and heavy industrial sectors. Mounted on the DS200DCCA base card, the IS220YDOAS1A interfaces with terminal boards like the IS200STCIH1A/2A, supporting up to 12 potential-free relays for SIL-compliant turbine control logic .

Engineered for compatibility with GE’s Mark VIe architecture, the IS220YDOAS1A REV G features dual RJ-45 Ethernet ports for redundant communication with I/O networks and a three-pin power input for 24–36 VDC operation. Its modular design allows seamless integration with GE’s ControlST software suite, enabling real-time diagnostics, relay status monitoring, and firmware updates. The board’s rugged enclosure and conformal coating ensure operation in harsh environments, with a wide temperature range (-30°C to +65°C) and resistance to vibration and electromagnetic interference .

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS220YDOAS1A REV G |

| Manufacturer | General Electric (GE) |

| Product Type | Safety Discrete Output I/O Pack |

| Interface Type | Dual Ethernet (RJ-45), DC-37 pin connector, 3-pin power input |

| Relay Capacity | 12 potential-free relays (SPST/DPST) |

| Input Voltage | 24–36 VDC (isolated) |

| Output Current | 2 A per relay |

| Communication Protocols | Ethernet Modbus TCP/IP, IONet |

| Power Requirements | 28 VDC ±10% (via base card) |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Weight | 0.9 kg (2.0 lb) |

| Vibration Resistance | 10–500 Hz, 2g |

| Isolation Voltage | 500 VDC |

| Redundancy Support | Dual Ethernet ports for network redundancy |

| Programming Software | GE ControlST |

Main Features and Advantages

The GE IS220YDOAS1A REV G stands out for its SIL-compliant safety logic and dual Ethernet redundancy. It supports fail-safe operation for emergency turbine shutdowns, ensuring compliance with industry safety standards. Each relay channel includes diagnostic feedback for open/closed status, enabling proactive maintenance and reducing downtime .

Another key strength is its modular architecture and hot-swappable design. The IS220YDOAS1A supports field replaceable units (FRUs), allowing engineers to replace faulty components without manual reconfiguration. GE’s ControlST software automatically downloads the latest firmware and configuration settings, minimizing maintenance complexity. The board also features multi-protocol support, including MODBUS TCP/IP and IONet, enabling seamless integration with third-party systems .

Additionally, the IS220YDOAS1A REV G offers scalable connectivity with other Mark VIe modules. Its DC-37 pin connector enables seamless integration with the PPDA (Power Supply Diagnostic I/O Package) for real-time power monitoring and with JPDF/JPDE modules for DC power distribution. This flexibility allows the board to be tailored to specific system requirements, from basic discrete output control to fully redundant configurations .

Application Areas

The GE IS220YDOAS1A REV G is primarily used in turbine control systems across industries requiring reliable safety-critical outputs:

- Power Generation: Controls steam and gas turbine valves, enabling precise speed regulation and emergency shutdowns. Integrates with SCADA systems for real-time performance optimization.

- Oil & Gas: Manages turbine-driven compressors and pumps in pipelines and refineries, enhancing safety and operational efficiency. Used in emergency shutdown systems to prevent mechanical damage.

- Heavy Manufacturing: Optimizes industrial turbines in steel production and water treatment plants, improving resource allocation.

- Marine Propulsion: Provides diagnostic feedback for shipboard turbine engines, reducing fuel consumption and maintenance costs.

By enabling high-speed discrete signal processing and redundant communication, the IS220YDOAS1A plays a vital role in maintaining turbine performance and reducing unplanned outages. Its compatibility with legacy and modern protocols also makes it suitable for retrofitting older systems to meet current industry standards .

Related Products

- IS420UCSCH1A: High-performance controller for Mark VIe systems, supporting SIL3 safety applications.

- DS200DCCA: Base card providing power and backplane connectivity for Mark VIe modules.

- IS220PCLAHIA: Core analog I/O module for integrating thermocouple and 4-20 mA signals.

- IS220PSCAHIA: Serial communication I/O module supporting MODBUS and PROFIBUS protocols.

- GE ControlST Software: Configures and monitors the IS220YDOAS1A, enabling advanced diagnostics and real-time control.

- IS200STCIH1A/2A: Terminal boards for signal conditioning and distribution, compatible with the IS220YDOAS1A.

Installation and Maintenance

Installation Preparation:

Ensure the IS220YDOAS1A is installed in a clean, dry environment with proper ventilation. Verify compatibility with the DS200DCCA base card and secure the board using anti-vibration mounts. Prior to powering up, check all wiring connections for accuracy, particularly the Ethernet and power interfaces. Use GE’s ControlST software to update firmware to the latest version and configure relay channels according to the turbine’s requirements .

Maintenance Recommendations:

Regularly inspect the IS220YDOAS1A for signs of physical damage or loose connections. Clean the board periodically to prevent dust accumulation, and ensure the operating temperature remains within the specified range. Monitor power supply voltage levels to avoid overloading, and replace aging components (e.g., relays) during scheduled outages. Perform quarterly firmware updates to access new features and security patches. For redundant systems, test communication failover mechanisms bi-annually to ensure seamless operation during faults .

Product Assurance

GE provides a 1-year warranty for the IS220YDOAS1A, covering defects in materials and workmanship. Authorized partners like Radwell and AX Control offer 2-year warranties on refurbished units, ensuring long-term system viability. GE’s global technical support team provides 24/7 assistance for installation, troubleshooting, and firmware updates. The company’s Predix platform enables remote monitoring and predictive maintenance, further enhancing uptime and operational efficiency. For discontinued products like the IS220YDOAS1A, GE’s certified partners also offer repair services, ensuring continued support for legacy systems .

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com