Description

Product Overview

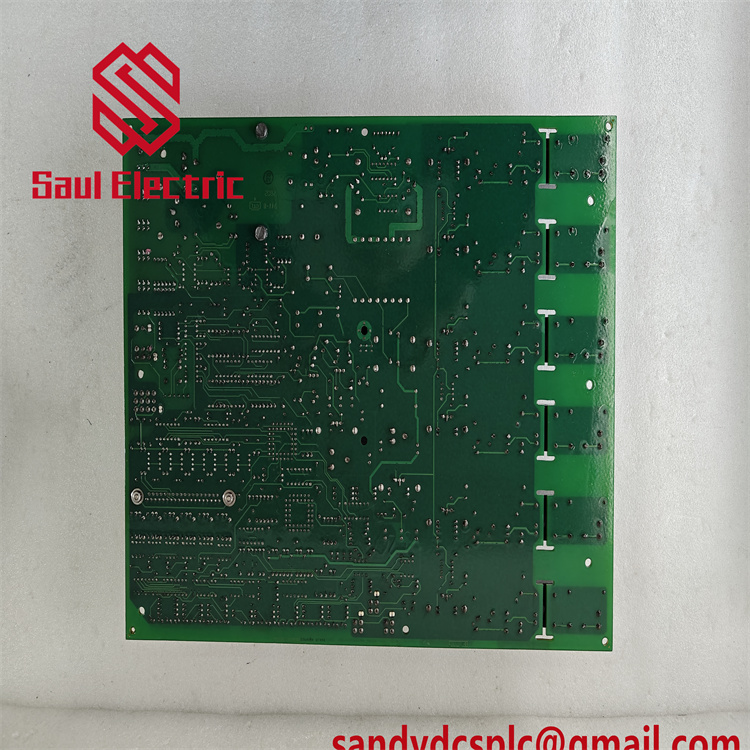

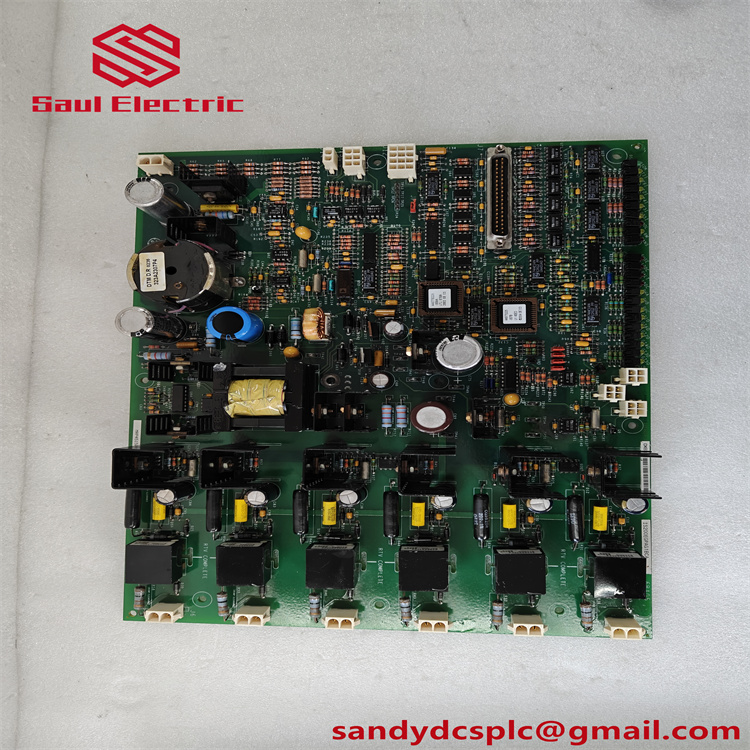

The GE IS220PVIBH1A, REV H is a high-precision Vibration Monitoring I/O Pack engineered by General Electric for the Mark VIe Speedtronic Turbine Control System. Designed to interface with vibration sensors (e.g., accelerometers, proximitors, velomitors) and terminal boards like TVBA, this module enables real-time detection of mechanical anomalies in critical industrial equipment. It processes analog vibration signals from up to 13 input channels, converting them into digital data for analysis via dual 100 Mbps Ethernet ports (EtherNet/IP or Modbus TCP). The GE IS220PVIBH1A, REV H operates reliably in extreme temperatures (-30°C to +65°C) with IP67-rated protection against dust, humidity (up to 95% RH), and corrosive environments, ensuring SIL 2-compliant safety in power plants and oil refineries. Its compact design (82.5 × 41.9 × 121.4 mm) integrates a 16-bit ADC for ±0.1% signal accuracy, preventing false alarms from electrical noise while supporting predictive maintenance for turbines, compressors, and rotating machinery.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS220PVIBH1A, REV H |

| Manufacturer | General Electric (GE) |

| Product Type | Vibration Monitoring I/O Pack |

| Input Channels | 13 (differential) |

| Compatible Sensors | Accelerometer, Velomitor, Proximitor, Seismic |

| Input Signal Range | -45 mV to +45 mV |

| ADC Resolution | 16-bit |

| Ethernet Ports | Dual 100 Mbps (RJ45) |

| Communication Protocols | EtherNet/IP, Modbus TCP |

| Operating Temperature | -30°C to +65°C |

| Power Supply | 24V DC ±10% |

| Dimensions | 82.5 × 41.9 × 121.4 mm (3.25″ × 1.65″ × 4.78″) |

| Weight | 0.38 kg |

| Protection Rating | IP67 |

| Certifications | UL, CE, CSA, ISO 9001 |

Key Features and Advantages

High-Fidelity Signal Processing:

The GE IS220PVIBH1A, REV H employs 16-bit ADC conversion with integrated DC bias elimination, ensuring ±0.1% accuracy in vibration amplitude/frequency measurements. Dual DACs dynamically adjust input ranges for Velomitor seismic sensors and accelerometers, suppressing noise in high-interference environments like steel mills (5G vibration tolerance).

Redundant Connectivity and Diagnostics:

Dual Ethernet ports enable fail-safe operation: If one network fails, data routes seamlessly through the second port without disrupting monitoring. Embedded diagnostics detect sensor faults (open-circuit/short-circuit) and relay alerts via ToolboxST software, reducing troubleshooting time by 40%.

Industrial Resilience:

Conformal-coated PCBs and IP67 housing withstand salt fog, methane exposure (ATEX Zone 2), and humidity up to 95%. Hot-swappable architecture allows module replacement during turbine operation, minimizing downtime for SIL 2 safety systems.

Application Areas

- Power Generation: Monitors gas/steam turbine bearings and rotors, triggering emergency shutdowns when vibrations exceed 12.7 mm/s RMS. SIL 2 compliance ensures zero false trips in critical plants.

- Oil & Gas: Deployed on offshore platforms to detect compressor imbalances (>50µm misalignment) in ATEX Zone 2 areas, resisting corrosion and methane explosions.

- Heavy Manufacturing: Supports vibration analysis in rolling mills, identifying motor misalignment via integrated accelerometer channels (1–3 kHz sampling).

Related Products

IS220PTCCH1A Thermocouple Input Module

IS220PSVOH1A, REV E – Servo Control I/O Module

IS200STCIH6A DIN-Rail Contact Terminal Board

IS200SPROH1ABC – Emergency Protection Terminal Board

Is400jgpag1a-terminal-board-for-pccah1a

Installation and Maintenance

Installation: Mount vertically on DIN rails with ≥20 mm clearance from high-voltage cables. Use shielded twisted-pair cables (AWG 18-22) for sensor connections to minimize EMI. Verify 24V DC input voltage (±10%) and ground resistance ≤0.1Ω.

Maintenance: Calibrate DAC bias quarterly via front-panel test points. Clean ventilation slots annually with dry nitrogen (<30 psi). Replace electrolytic capacitors after 60,000 operational hours (≈7 years) to prevent signal drift.

Product Assurance

GE offers a 12-month global warranty covering material defects. Units undergo MIL-STD-810H testing (thermal shock, vibration) with an MTBF exceeding 150,000 hours. Critical failure support includes 24/7 remote diagnostics and 48-hour replacement for power generation sites.

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com