Description

Product Overview

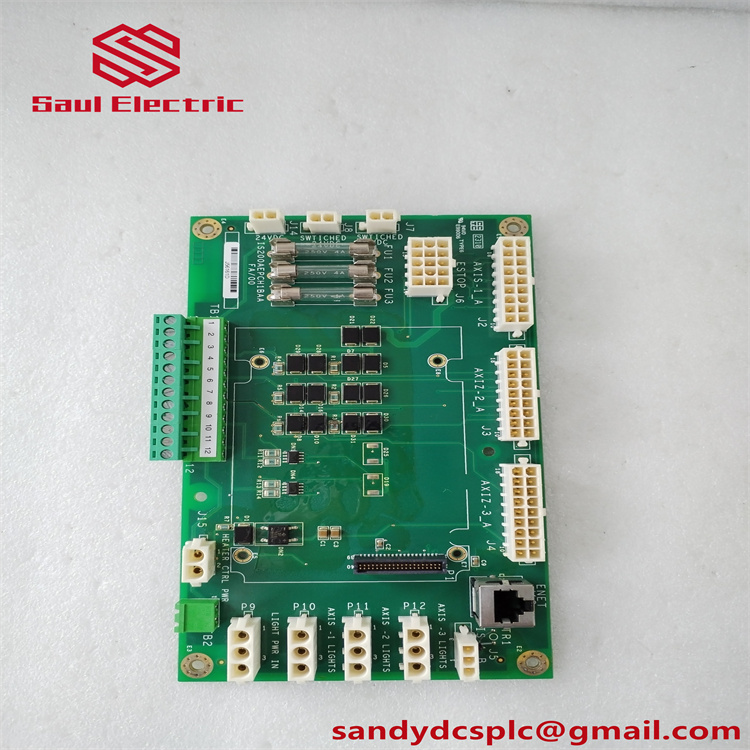

The GE IS220PTURH1A, REV D is a high-reliability Primary Turbine Protection Pack engineered by General Electric for critical safety functions in gas/steam turbine control systems within the Mark VIe Speedtronic platform. Designed to prevent catastrophic failures, this module integrates advanced diagnostics and rapid trip logic to monitor turbine speed, vibration, and temperature parameters, triggering sub-millisecond safety shutdowns during overspeed (>110% RPM) or mechanical fault conditions. Its dual-slot architecture supports seamless redundancy configurations, while the passive magnetic speed input circuit detects rotational speeds as low as 2 RPM, ensuring precise monitoring of turbine coast-down phases. Encased in a black industrial-grade alloy housing with optimized thermal dissipation, the GE IS220PTURH1A, REV D operates reliably across temperatures from -20°C to +50°C (extended range: -40°C to +60°C per variant data), making it indispensable for power plants and heavy industries demanding fail-safe protection .

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | IS220PTURH1A, REV D |

| Manufacturer | GE (General Electric) |

| Product Type | Turbine Protection I/O Pack |

| Input Voltage | 24 V DC ±10% |

| Power Consumption | ≤15 W |

| Speed Detection Range | 2 RPM–10,000 RPM |

| Trip Response Time | <100 ms |

| Communication Ports | 2× Ethernet, 1× IR (diagnostic) |

| Operating Temperature | -20°C to +50°C (standard) |

| Protection Rating | IP54 (dust/moisture resistant) |

| Dimensions (W×H×D) | 292 × 130 × 27 mm |

| Weight | 0.32 kg |

| Certifications | UL, CE, ISO 9001 |

Note: Thermal tolerance may extend to -40°C/+60°C in specific configurations .

Main Features and Advantages

Critical Fault Protection:

The GE IS220PTURH1A, REV D employs four passive magnetic speed inputs to continuously monitor turbine rotation, detecting micro-level anomalies (e.g., 2 RPM coast-down) and executing overspeed trips within 100 ms—preventing mechanical disintegration during grid failures or load rejection events. Integrated auto-reconfiguration syncs firmware/parameters with controllers via Ethernet, eliminating manual calibration errors .

Industrial Resilience:

Housed in a fanless, EMI-shielded alloy chassis with IP54-rated sealing, the module withstands vibration (IEC 60068-2-6) and corrosive atmospheres common in turbine halls. Front-panel LEDs (Power, Fault, Online) provide instant health visibility, while the IR port enables non-intrusive diagnostics during operation .

Redundancy and Integration:

Dual Ethernet ports enable parallel connectivity to Mark VIe controllers and plant networks (Modbus RTU/Ethernet IP). Compatible with terminal board IS200TRPAH1A, the module supports hot-swap replacements in redundant setups, minimizing downtime during maintenance .

Application Areas

- Power Generation: Primary overspeed protection for gas/steam turbines in combined-cycle plants, synchronizing with Speedtronic Mark VIe controllers to enforce ANSI/IEEE C37.96 safety margins .

- Industrial Turbomachinery: Monitors compressors and pumps in oil refineries, triggering emergency stops on excessive vibration or bearing failure .

- Renewable Energy: Safeguards gearbox integrity in wind turbines by detecting rotor overspeed during storm conditions .

Related Products

- IS220PTURH1B: Enhanced version with wider temperature range (-40°C to +85°C) for Arctic operations .

- IS220YTURS1A: SIL-3 certified variant for nuclear turbine protection, compliant with IEC 61508 .

- IS200TRPAH1A: Terminal board for wiring speed sensors and trip relays to IS220PTURH1A, REV D .

- IS220PAICH1A: Analog I/O pack for complementary pressure/temperature monitoring in turbine systems .

- ControlST Toolbox: Software suite for configuring auto-replication and diagnostics .

Installation and Maintenance

Installation Preparation: Verify DC input voltage (24 V ±10%) and allocate ≥50 mm lateral clearance for heat dissipation. Mount on DIN rail using M4 screws, connecting speed sensors to IS200TRPAH1A terminal board via shielded twisted-pair cables. Enable auto-reconfiguration in ControlST before commissioning.

Maintenance Recommendations: Clean air vents quarterly with dry compressed air. Test trip logic annually using simulated overspeed signals. Replace modules during planned outages; redundant configurations permit live swaps. Monitor Fault LED for early warnings (e.g., temperature drift).

Product Assurance

GE provides a 12-month warranty covering defects. Global support includes 24/7 remote diagnostics and expedited replacement (3–5 days delivery from certified warehouses). Units comply with IEC 62443 cybersecurity standards and ISO 13849 (PL-e) functional safety requirements .

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com