Description

Product Overview

The GE IS220PSVOHIA, REV D is a high-performance Servo Control Module designed for GE’s Mark VIe turbine control system, a cornerstone of industrial automation in power generation and heavy machinery. As a critical component of distributed I/O architectures, this module enables precise control of servo valves and other high-precision actuators, ensuring seamless integration between the central controller and field-level devices.

The GE IS220PSVOHIA, REV D is a high-performance Servo Control Module designed for GE’s Mark VIe turbine control system, a cornerstone of industrial automation in power generation and heavy machinery. As a critical component of distributed I/O architectures, this module enables precise control of servo valves and other high-precision actuators, ensuring seamless integration between the central controller and field-level devices.

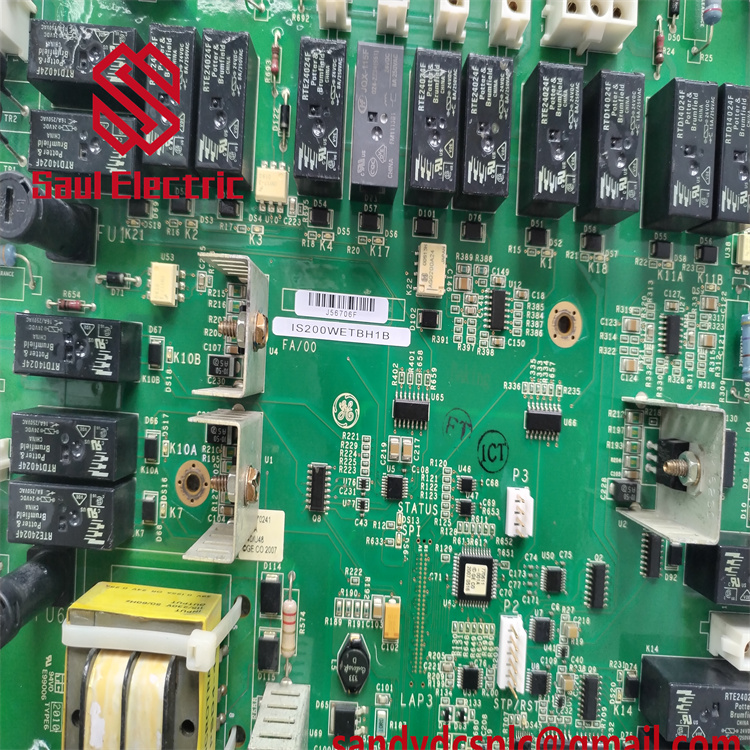

Engineered for gas and steam turbine applications, the IS220PSVOHIA, REV D acts as an electrical interface between one or two I/O Ethernet networks and a TSVO servo terminal board1314. It supports dual independent servo valve position loops, delivering real-time control with 24V DC power input and 2.5A current capacity. The module features a conformal-coated PCB for enhanced durability in harsh environments, along with IP20-rated protection against dust and light splashes17. With a compact form factor (420 x 280 x 180 mm) and -20°C to +60°C operating temperature range, it excels in demanding industrial settings, including power plants, petrochemical facilities, and marine propulsion systems.

Leveraging Modbus RTU/ASCII protocols and dual RJ45 Ethernet ports, the IS220PSVOHIA, REV D ensures fast, secure communication with the host controller. Its diagnostic capabilities, including LED status indicators (Power, Attention, TXRX, Link) and infrared serial port access, simplify troubleshooting and maintenance. This module is fully compatible with GE’s Control System Toolbox software, allowing remote configuration and auto-reconfiguration when replaced, minimizing downtime during system upgrades.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS220PSVOHIA, REV D |

| Manufacturer | General Electric (GE) |

| Product Type | Servo Control Module |

| Series | Mark VIe |

| Compatibility | TSVO servo terminal board |

| Communication Protocols | Modbus RTU, Modbus ASCII |

| Ethernet Ports | 2 x 10/100 Mbps RJ45 |

| Power Supply | 24V DC, 2.5A |

| Control Loops | Dual independent servo loops |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Physical Dimensions | 420 x 280 x 180 mm |

| Weight | ~13 kg |

| Certifications | UL 508, CE, CSA |

Key Features and Advantages

Dual Servo Loop Control: The IS220PSVOHIA, REV D supports two independent servo valve position loops, enabling precise control of critical processes like turbine speed regulation and steam flow management. This dual-loop design enhances system redundancy and reliability in mission-critical applications.

Dual Servo Loop Control: The IS220PSVOHIA, REV D supports two independent servo valve position loops, enabling precise control of critical processes like turbine speed regulation and steam flow management. This dual-loop design enhances system redundancy and reliability in mission-critical applications.

Robust Communication: With dual Ethernet ports and Modbus protocol support, the module ensures seamless data exchange between the control system and field devices. The auto-negotiation feature (10/100 Mbps, half/full duplex) adapts to varying network conditions, while Ethernet redundancy prevents communication failures.

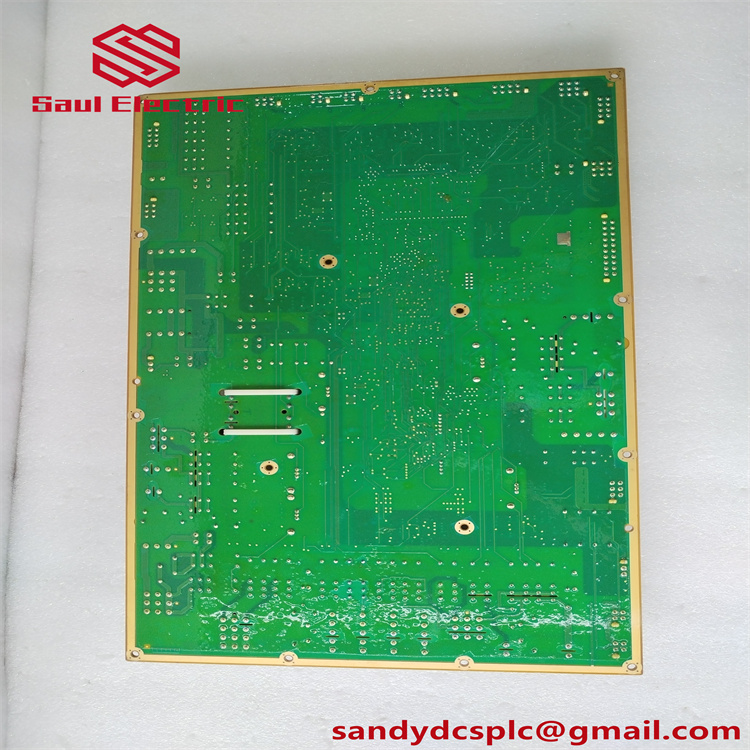

Harsh Environment Resilience: The conformal-coated PCB and IP20 enclosure protect against moisture, dust, and vibration, making it suitable for extreme industrial environments. Its wide temperature range (-20°C to +60°C) ensures stable operation in both indoor and outdoor installations.

Simplified Maintenance: Onboard diagnostics, including LED status indicators and infrared serial port access, streamline fault detection and repair. The module’s auto-reconfiguration capability (enabled via Control System Toolbox) reduces downtime during replacement, while modular construction allows quick component swaps.

High Performance: With 24V DC power input and 2.5A current capacity, the module delivers consistent performance even under heavy loads. Its surface-mount technology ensures high-quality construction and long-term durability.

Application Areas

The GE IS220PSVOHIA, REV D is widely used in industries requiring precise servo control and reliable communication:

The GE IS220PSVOHIA, REV D is widely used in industries requiring precise servo control and reliable communication:

- Power Generation: Manages steam and gas turbine servo valves to optimize energy output and reduce emissions.

- Oil & Gas: Controls compressors and pumps in offshore platforms and refineries, ensuring efficient fluid handling.

- Marine Propulsion: Regulates engine speed and thrust in naval vessels and commercial ships.

- Industrial Automation: Integrates with robotics and CNC machines for high-precision manufacturing processes.

- Water Treatment: Controls actuators in filtration systems and wastewater treatment plants, ensuring compliance with environmental standards.

Related Products

IS220PTCCH1A Thermocouple Input Module

IS220PSVOH1A, REV E – Servo Control I/O Module

IS200STCIH6A DIN-Rail Contact Terminal Board

IS200SPROH1ABC – Emergency Protection Terminal Board

Is400jgpag1a-terminal-board-for-pccah1a

Installation and Maintenance

Installation Preparation:

Before installing the IS220PSVOHIA, REV D, ensure the Mark VIe backplane is powered off and properly grounded. Verify compatibility with the TSVO servo terminal board and confirm cable specifications (75 Ohm coaxial) to avoid signal degradation. Use GE’s Control System Toolbox software to configure network parameters and enable auto-reconfiguration settings.

Installation Preparation:

Before installing the IS220PSVOHIA, REV D, ensure the Mark VIe backplane is powered off and properly grounded. Verify compatibility with the TSVO servo terminal board and confirm cable specifications (75 Ohm coaxial) to avoid signal degradation. Use GE’s Control System Toolbox software to configure network parameters and enable auto-reconfiguration settings.

Maintenance Recommendations:

Regularly inspect the module for physical damage or loose connections, particularly in high-vibration environments. Clean dust and debris from vents to prevent overheating. Monitor LED status indicators for error codes and perform firmware updates quarterly to leverage the latest security patches and performance optimizations. Replace worn-out Ethernet cables every 5 years or as per environmental conditions.

Regularly inspect the module for physical damage or loose connections, particularly in high-vibration environments. Clean dust and debris from vents to prevent overheating. Monitor LED status indicators for error codes and perform firmware updates quarterly to leverage the latest security patches and performance optimizations. Replace worn-out Ethernet cables every 5 years or as per environmental conditions.

Product Warranty

GE provides a 1-year warranty for the IS220PSVOHIA, REV D, covering defects in materials and workmanship. This includes free replacement or repair services, backed by a global network of certified technicians. For mission-critical applications, extended warranties and proactive maintenance plans are available to further reduce downtime risks. Technical support is accessible 24/7 via phone, email, and GE’s online knowledge base, ensuring rapid resolution of operational challenges.

GE provides a 1-year warranty for the IS220PSVOHIA, REV D, covering defects in materials and workmanship. This includes free replacement or repair services, backed by a global network of certified technicians. For mission-critical applications, extended warranties and proactive maintenance plans are available to further reduce downtime risks. Technical support is accessible 24/7 via phone, email, and GE’s online knowledge base, ensuring rapid resolution of operational challenges.

HS:8471800000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com