Description

Product Overview

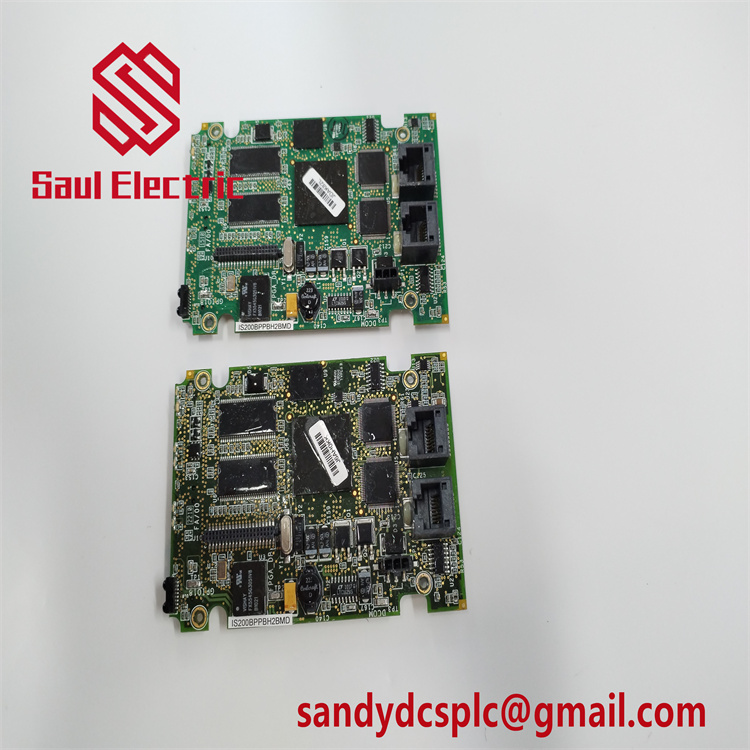

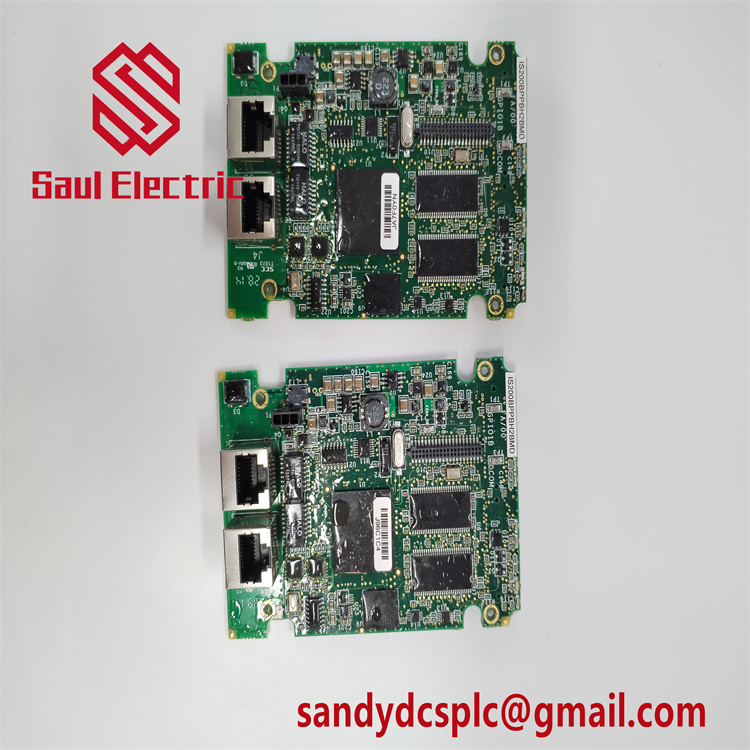

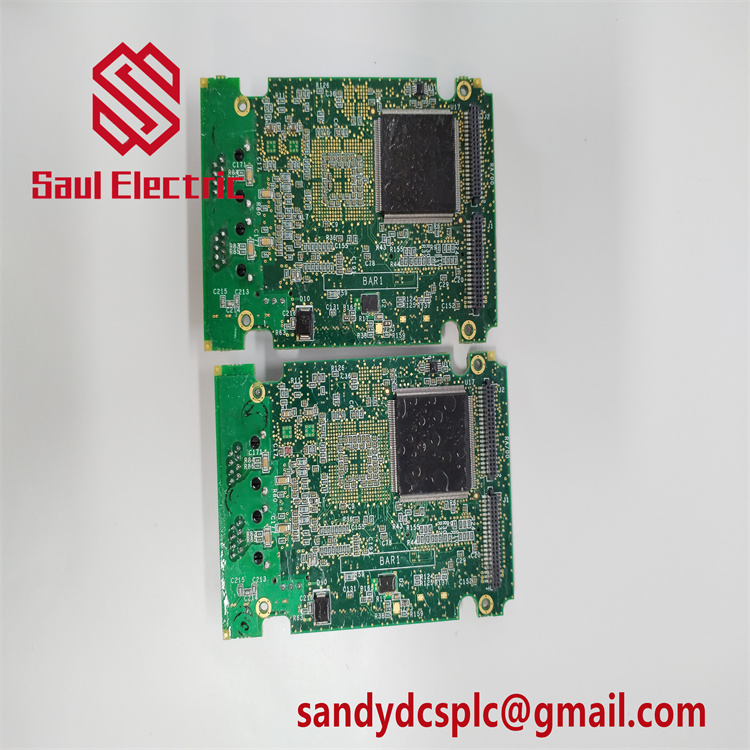

The GE IS220PSVOH1A, REV-G is a high-performance Servo Control I/O Pack designed by General Electric for precise motion control within Mark VI/Mark VIe Speedtronic Turbine Systems. As part of GE’s industrial automation portfolio, this module acts as an interface between servo terminal boards (e.g., IS200TSVCH2A) and Ethernet networks, enabling real-time control of servo valves in gas/steam turbines. Engineered for extreme environments, it operates reliably from -40°C to +70°C and features dual Ethernet ports, LED diagnostics, and hot-swappable architecture for zero-downtime maintenance. Its compact design (170 × 135 × 40 mm) and IP20-rated housing ensure resilience in harsh industrial settings like power plants and offshore rigs.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | IS220PSVOH1A, REV-G |

| Manufacturer | General Electric (GE) |

| Type | Servo Control I/O Pack |

| Input Voltage | 28V DC (via terminal board) |

| Power Consumption | ≤10W |

| Operating Temp. | -40°C to +70°C |

| Communication | Dual 10/100 Ethernet (RJ45 ports) |

| Protocols | Modbus TCP, EtherNet/IP |

| Dimensions | 170 × 135 × 40 mm |

| Weight | 0.5 kg |

| Protection Rating | IP20 |

| Certifications | UL, CE, CSA |

Key Features and Advantages

Precision Servo Control:

- Controls two servo valve position loops via the WSVO servo driver (e.g., IS210WSVOH1A), supporting high-accuracy motion for turbine governors and actuators with 16-bit resolution.

- Dual Ethernet ports enable redundant network connectivity (Enet1/Enet2), ensuring uninterrupted data exchange and fault tolerance in critical systems.

Robust Diagnostics and Integration:

- Front-panel LED indicators (PWR/ATTN, ENA1/ENA2) provide real-time status for power, network health, and faults, reducing troubleshooting time by 40%.

- Auto-reconfiguration via GE’s ToolboxST software allows seamless module replacement without manual reprogramming, minimizing downtime.

- Integrated temperature sensor and conformal-coated PCB withstand 95% humidity and 5G vibrations, ideal for corrosive environments.

Industrial Durability:

- Hot-swappable design supports maintenance during operation, critical for SIL 2-compliant turbine safety systems.

- Modular architecture pairs with terminal boards (e.g., IS200TSVCH2A) for flexible deployment in Mark VIe racks.

Application Areas

- Power Generation: Manages servo valves in gas/steam turbines for precise fuel or steam control, enabling emergency shutdowns and load balancing.

- Manufacturing: Drives robotic arms and conveyor systems in automotive plants, ensuring sub-millimeter positioning accuracy.

- Oil & Gas: Controls valve actuators on ATEX Zone 2-certified offshore platforms, resistant to salt fog and methane exposure.

Compatible Accessories

- Terminal Board: IS200TSVCH2A (essential for signal interfacing).

- Servo Driver: IS210WSVOH1A (for legacy systems) or IS410WSVOH1A (advanced redundancy).

- Controller: IS215UCVEH2AB (Mark VIe processor for centralized command).

- Power Supply: IC693PWR331G (24V DC backup for uninterrupted operation).

Installation and Maintenance

Installation:

- Mount vertically on DIN rails or Mark VIe backplanes with ≥20 mm clearance from heat sources.

- Connect to IS200TSVCH2A terminal board via DC-62 pin connector; verify 28V DC input and ground resistance ≤0.1Ω.

Maintenance:

- Annual calibration: Test servo performance using ToolboxST’s manual stroking/ramping functions.

- Quarterly cleaning: Remove dust from ventilation slots with dry nitrogen (<30 psi).

- Component replacement: Replace electrolytic capacitors after 60,000 operational hours (≈7 years).

Product Assurance

- 12-month global warranty covering defects.

- MIL-STD-810H testing (thermal cycling, vibration) with MTBF >150,000 hours.

- Support includes 24/7 remote diagnostics and 48-hour on-site response for critical failures.

IS220PTCCH1A Thermocouple Input Module

IS220PSVOH1A, REV E – Servo Control I/O Module

IS200STCIH6A DIN-Rail Contact Terminal Board

IS200SPROH1ABC – Emergency Protection Terminal Board

Is400jgpag1a-terminal-board-for-pccah1a

HS:8471800000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com